Administration of the project

Friction has memory

Experiments show that the friction between two surfaces depends on their history of contact and that this “memory” is reminiscent of the behavior of glasses.

Contrary to what you may have learned in high school, friction between two surfaces is not constant. For a wide range of materials and surface types, it increases with time, as microscopically uneven surfaces deform and come into closer contact. Experiments now find an additional wrinkle: friction can have a memory, meaning that it can depend not only on the current state of the interface but also on how it got there. The findings hint at connections between friction and the behavior of glasses and other disordered systems and, in the long run, may influence how scientists think about friction associated with earthquakes, industrial machinery, and micromachines.

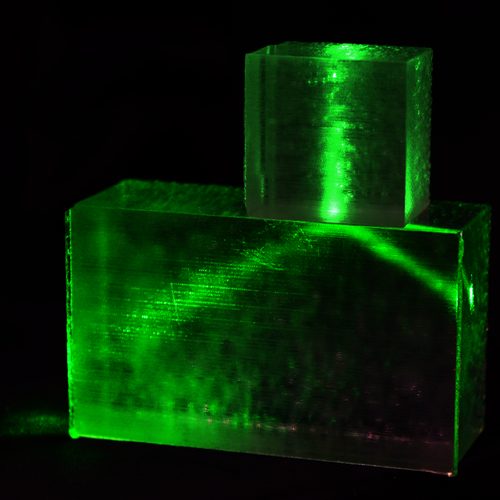

Traditional models of the “aging” of friction assume that the frictional resistance depends only on conditions at the interface and on the duration of contact. Shmuel Rubinstein and graduate student Sam Dillavou of Harvard University put this assumption to the test by means of a novel experiment that measured the response of friction to a change in the force at the interface. They placed pairs of clear plastic slabs, one on top of the other, with surface areas of 0.5 to 4 square centimeters, in a device that allowed a chosen force (the “load”) to push down on the top slab.

To measure the actual area of contact between the two slightly rough surfaces, the duo used a technique Rubinstein co-developed that involves shining light at a low angle onto the top surface of the lower slab. The light passes into the upper slab in a patchy pattern because it crosses the interface only where there is true contact. In the first step of the experiment, Dillavou and Rubinstein applied a constant load to the upper slab. The contact area grew logarithmically with time, as expected from many prior studies of friction under fixed conditions.

In the second step, the researchers abruptly reduced the load after a “waiting” time ranging from a few seconds to nearly three hours. The area of contact fell suddenly at first, as many small regions detached. It then continued to fall slowly for an extended period of time before resuming the rising logarithmic trend of the first step. The fall and rise imply that the frictional interface has a memory. Under the same external conditions, the contact area passed through the same value twice, which means that it cannot depend only on those conditions but must also depend on the history of the interface.

In another set of experiments, Dillavou and Rubinstein measured the coefficient of friction, which is defined as the force needed to make the interface slip divided by the load. They used the same two-step procedure, but after the waiting time and the abrupt reduction in load, they applied a steadily increasing lateral force to the lower slab until it slipped. The researchers conducted thousands of such tests for different values of the waiting time and the initial and reduced loads.

The friction coefficient also fell and rose again after the load reduction, but comparison with the contact area measurements for the same parameters showed that the two properties did not vary in concert. Sometimes the area of contact rose when the friction coefficient fell, and vice versa. The patchiness of the actual contact between the slabs explains this mismatch, the researchers say. The coefficient of friction depends mainly on a fraction of the interface where contact is strongest, and if those areas shrink while more numerous but weaker contact areas grow, the total area of contact could rise even while the friction coefficient falls. However, Rubinstein admits that it’s not clear why some areas would have larger contact but less friction.

To account for the behavior of both parameters, Dillavou and Rubinstein turned to an empirical model that pictures disordered systems, such as glasses, as collections of numerous microsystems that evolve at different rates in response to changing conditions [1]. In the case of friction, these microsystems could be tiny regions undergoing deformation or adhesion at the interface. In the two-step experiments, rapidly evolving microsystems reach equilibrium during the waiting time, while slower ones are still changing. After the load is abruptly reduced, these groups evolve differently as they move toward the new equilibrium, producing the observed behavior.

Ben Lishman of South Bank University in London, who studies motion and friction in sea ice, finds the new report “fascinating” and says that it may help scientists “understand what friction really is” at a microscopic scale. He adds, however, that empirical models of friction mostly work well, so it may take some time for the new insights to influence those models.

This research is published in Physical Review Letters.

Material provided by Physics Forum.

References

- A. Amir, Y. Oreg, and Y. Imry, “Mean-Field Model for Electron-Glass Dynamics,” Phys. Rev. B 77, 165207 (2008); “Slow Relaxations and Aging in the Electron Glass,” Phys. Rev. Lett. 103, 126403 (2009).

Be the first to comment