Administration of the project

Fretting, fretting corrosion and fretting mechanisms

Table of Contents

What is fretting?

Fretting or fretting wear is a specific wear type which is characterized by low amplitude oscillating sliding between bodies, which are nominally at rest [1] (for example due to vibration, cyclic stresses, etc). The amplitude of sliding may vary from tens of mircons (in bolted joints, electrical contacts) to tens of nanometers (in MEMS). Fretting typically appears as pits or grooves surrounded by corrosion products. Fretting is usually accompanied by corrosion (in a corrosive environment).

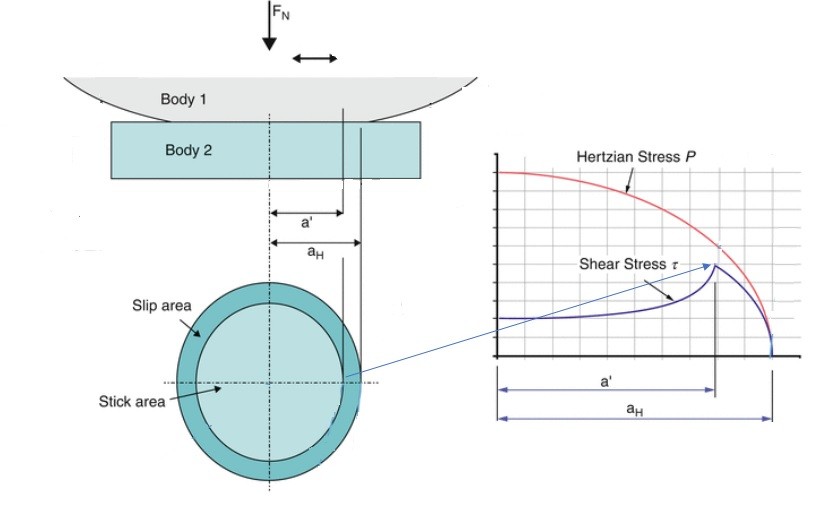

In fretting there is no macroscopic sliding. The surfaces are nominally in static contact in the central region of a contact (for a ball on flat case), where the normal pressure is high. At the periphery, where the pressure is low and the tangential traction is sufficiently high to overcome the static friction, microslip occurs. Figure 1 shows stick and slip zones in a fretting contact.

Fretting is a combination of abrasive and adhesive wear, where under applied normal load adhesive junctions occur, while the oscillating motion causes rupture of the material in a form of debris. Debris typically get entrapped in the contact and form rolls which act like bearings [2]. This may lead to reduction of coefficient of friction with time.

Fretting corrosion

Corrosion often develops under fretting condtions, a wear mode known as fretting corrosion. Due to rupture of the material and formation of debris, the fresh surface is exposed to air and subsequently it is prone to oxidation (it depends on the inertness of the material). In case of steel, the iron oxide is very hard and thus acts as an abrasive. Since the particles cannot escape the contact, they initiate abrasive wear and subsequent oxidation and the process continues. This may lead to elevated wear volumes, as compared to abrasive or adhesive wear modes independently.

Fretting test

Fretting tests are used to determine the effects of several fretting parameters on the performance of materials. These parameters include differing materials, relative displacement amplitudes, normal force at the fretting contact, alternating tangential force, the contact geometry, surface integrity parameters such as finish, and the environment testing environment. The results may be used for selecting material combinations, design stress levels, lubricants, and coatings to alleviate or eliminate fretting concerns in new or existing designs. Various fretting testers are commercially available. In the video below a typical fretting test operation is shown (in a gross sliding, also called linear reciprocating regime):

Fretting corrosion mechanism

Typically, three stages of fretting can be distinguished [3]:

1. In the the first stage metallic contact between two surfaces occurs on asperity level (cold welding, adhesion). This happens, if the protective oxide layer is broken down, so that highly reactive bare materials come into contact. The contact occurs at few asperities (i.e., surface protrusions).

2. In the second stage debris are generated and subsequently oxidated. It is difficult for particles to escape the contact since the amplitude of motion is limited and therefore they act as abrasives, which may increase the wear rate.

3. In the third stage, fretting fatigue develops. Due to repeated loading (normal and shear stresses), the elevated stress area in fretting occurs on the sides of the loaded area. Therefore, the crack initiates at the boundaries of the fretting area and propagates inside.

Fretting fatigue

In fretting contact surfaces are worn and, at the same time, they are affected by cyclic friction stress. Fatigue with fretting is called fretting fatigue [4]. The friction stress is maximum on the contact surface of the material and decreases drastically toward the inside of the material. Therefore, fretting fatigue crack growth behavior differs significantly from fatigue crack growth behavior in friction-less fatigue [5]. In fretting fatigue, the growth rate of a crack near the contact surface decreases drastically with increasing crack length. Then, after showing a minimum value, it is in accord with the plain fatigue crack growth rate. The fretting fatigue strength is often half or less of the plain fatigue strength and it will not become higher even if the tensile strength of the material is increased [5].

Fretting fatigue life is shorter than plain fatigue life. In fretting fatigue, a crack easily nucleates due to friction stress even at a small stress amplitude at which plain fatigue failure may not occur. Ultimtely, the crack grows leading to the failure of the material. In orthopedic implants, fretting occurs where two materials come into contact with each other; such as in bone plates or screws.

Factors affecting fretting

- Contact load: Wear is a linear function of load and fretting would, therefore, increase with increased load as long as the amplitude is not reduced.

- Amplitude: No measurable threshold amplitude exists below which fretting does not occur. An upper threshold limit, however, may exist at which the transition of wear rate to the regular sliding type occurs.

- Number of cycles: The degree of fretting increases with the number of cycles. An incubation period is reported to exist during which the damage is negligible. This period is followed by a steady-state period with a constant wear rate. Further, the rate of fretting wear is increased.

- Temperature: Temperature has a significant impact on the rate of chemical reactions and therefore on oxidation of materials. At elevated temperatures, the oxide formation rate is high and the oxide layer acts as a protective layer. This layer protects bare materials from coming into contact and forming adhesive junctions (cold welding). Thus the wear rate is reduced with an increase of temperature.

- Relative humidity: Typically, increased humidity reduces the fretting corrosion. It is believed to be a consequence of increased oxidation rate in presence of water and thus formation of a protective layer.

- Inertness of materials [6]: the ability of the materials to react with oxygen directly impacts the fretting fatigue.

References

- [1] Fretting Corrosion. Von R. B. Waterhouse. 253 S. 306 Abb., 13 Tab. 1972, Pergamon Press, Oxford, New York, Toronto, Sydney, Braunschweig

- [2] Friction Science and Technology: From Concepts to Applications, Peter J. Blau,

- [3] Zaki Ahmad, in Principles of Corrosion Engineering and Corrosion Control, 2006

- [4] Mechanical testing of metallic biomaterials, N. Maruyama, in Metals for Biomedical Devices, 2010

- [5] R.B. Waterhouse, Fretting wear, Wear, 1984

- [6] Engineering Tribology, Gwidon W. Stachowiak, Andrew W. Batchelor, Third Edition, 2005

Leave a Reply

You must be logged in to post a comment.

hello.

i want to enquire whether fretting wear can occur in suspension front forks of motor cycles.

as the front forks continuously undergo reciprocating motion, under contact between hard chrome plating and various sealings generally made up of NBR rubber,PTFE etc, is there any chance of fretting wear on the front forks?

Hello,

I just read the article abot fretting.

Thank’s for that clear explanations.

For me I made the conlusion that bearings installaed at low tmepeatures e.g. -20°C might therefore be more affected by fretting (low temperatures in combination with low absolute humidity).

Is that a valid conclusion?