Founder of TriboNet, Editor, PhD (Tribology), Tribology Scientist at ASML, The Netherlands. Expertise in lubrication, friction, wear and contact mechanics with emphasis on modeling. Creator of Tribology Simulator.

Molecular Dynamic Simulations of Zinc Phosphate – Iron Oxide Reaction

In order to improve wear resistance of the surfaces operating in harsh conditions, along with base oils additives are frequently used. ZDDP is one of the best additives in terms of antiwear performance, however, environmentally unfriendly. The search for a new, environmentally friendly and antiwear efficient substitute for ZDDP is an ongoing process. Development of such a substitute, requires a clear understanding of ZDDP antiwear mechanism.

It is well understood, that the antiwear mechanism is linked to the generation of the tribofilm. The tribofilm formed by the ZDDP (50-200nm thick), mainly consists of oxygen, phosphate, sulfide, zinc and iron, with the increase of amount of iron away from the surface. The polyphosphate glasses are considered to be responsible for the antiwear action in the mild wear situation. However, the exact mechanism is not clear. Different theories exist. One assumes that the tribofilm during the rubbing is in magma or possibly in plasma state (see also triboplasma). After the end of the test (when the analysis of the tribofilm is performed), the temperature and pressure is decreased, so the magma or plasma state is changed to the solid state. This is supported by the observations of tribofilm flow patterns and its amorphous structure. Besides, the tribofilm surface is very homogeneous and smooth. The antiwear action is then related to a lubrication type – generation of the liquid layer, which separates the surfaces and decrease the wear. According to another theory, there is a pressure and shear induced chemical reaction between phosphates and iron oxide, which results in formation of mixed zinc – iron phosphate glass. This glass is then worn and therefore, the bulk material is only worn through the chemical reaction and not through the mechanical action.

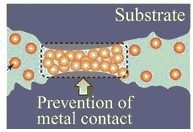

An international team of researchers from France and Japan studied the possible antiwear mechanisms using Molecular Dynamic simulations. The model was developed to explore the reaction occurring during friction between zinc metaphosphate glass (main constituent of ZDDP, non-crystalline, highly amorphous solid) and steel native oxide. A long-chain amorphous zinc metaphosphate layer ![]() was built and slid against an amorphous iron oxide layer

was built and slid against an amorphous iron oxide layer ![]() under 1 GPa pressure. The presence of the base oil was omitted to simplify the model. The interatomic potentials of the phosphate and oxide included long range Columbic interactions and exchange repulsion energy terms. A good agreement with experimentally measured density of

under 1 GPa pressure. The presence of the base oil was omitted to simplify the model. The interatomic potentials of the phosphate and oxide included long range Columbic interactions and exchange repulsion energy terms. A good agreement with experimentally measured density of ![]() and

and ![]() was observed in the model, indicating applicability of the employed interatomic potential. On top of it, the elastic modulus of iron oxide was found to be 256GPa (experimental value 214-350GPa).

was observed in the model, indicating applicability of the employed interatomic potential. On top of it, the elastic modulus of iron oxide was found to be 256GPa (experimental value 214-350GPa).

The MD simulation was performed and the interface between layers was studied in detail. It was found, that the mixed layer of zinc and iron phosphate glass was formed due to migration of the Fe atoms into ![]() layer and the migration was facilitated by sliding. The reaction of phosphate and oxide gave a mixed zinc – iron phosphate glass. The suggested antiwear mechanism is developed by a strong adhesion of phosphate to steel surface and chemical digestion of the iron oxide, eliminating the generation of abrasive wear particles. Therefore, the MD simulations mainly support the chemical reaction antiwear theory.

layer and the migration was facilitated by sliding. The reaction of phosphate and oxide gave a mixed zinc – iron phosphate glass. The suggested antiwear mechanism is developed by a strong adhesion of phosphate to steel surface and chemical digestion of the iron oxide, eliminating the generation of abrasive wear particles. Therefore, the MD simulations mainly support the chemical reaction antiwear theory.

On the other hand, during the simulations, the flow of the zinc polyphosphate was observed. Under extreme conditions, the layer changed from solid to liquid like state. The authors note, that the MD simulations require significantly higher speeds (100 m/s) compared to the experimental conditions (order of 1 m/s). It makes it difficult to state with confidence that the change to liquid like form takes place in reality and further research is needed to support this theory.

The details of the simulations can be found in the original article Experimental and Molecular Dynamics Simulations of Tribochemical Reactions with ZDDP: Zinc Phosphate–Iron Oxide Reaction, Minfray, C. et al.

Credit for image: Experimental and Molecular Dynamics Simulations of Tribochemical Reactions with ZDDP: Zinc Phosphate–Iron Oxide Reaction, Minfray, C. et al.

Leave a Reply

You must be logged in to post a comment.

Selfishly, I wish these researchers would refocus their efforts away from ZDDP tribolayer mechanics and on to the characterization of triboplasma events.