Generating electricity through friction

Electricity is considered as a basic necessity for humans just like food, water and shelter. Ironically, if we think about it we need electricity to make food, water and shelter nowadays. In its early days, electricity was generated through coal and petroleum, which takes serious man hours, life risk and is very harsh towards the climate. Now we are technologically advanced to an extent that, we are able to generate electricity by merely applying pressure on certain type of materials, though this idea has been around for quite some time in the form of piezoelectricity. The idea of electricity through friction is under serious consideration and have been consistently proven to be a hopeful source through research. But there are a few drawbacks in these devices as well. Such as, the generated current is too low to make a difference or the life cycle of the devices is very poor for long term usage. But a group of scientists from Tsinghua University in China had a breakthrough, which might change perspectives and also alter the course of research in this field.

Broadly speaking we can classify nano-generators of electricity into three categories, namely Triboelectric nanogenerator, Piezoelectric nanogenerator and Electret-based microgenerators. In this experiment the researchers used sliding Schottky generators, which produce direct current using sliding Schottky junctions. The advantage of using this generator is, its simple structure and the ability to produce high current densities. Generally, this kind of generators under practice require a pressure of 1-10 GPa which generate a current of 10000 – 10,00,00,000 A/m². But as a drawback its life cycle is usually 1-5 cycles only. If we go for generators with larger life cycles such as around 3600 – 10000 life cycles the drawback is with the current generated being a mere 0.033 A/m².

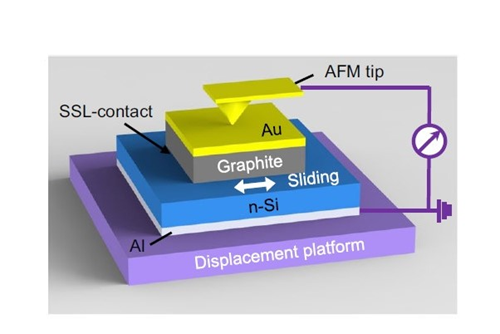

Fig1: Structure of generator under discussion

The generator which was developed by the researcher’s produce very ambitious numbers such as a life cycle of 5000 cycles with the ability to induce maximum current of 210 A/m² by overcoming the above discussed drawbacks. It is important to understand that the current order is thrice of any other reported TENGs or PENGs until now. This generator is designed in three steps. Initially a graphite flake from a graphite mesa of 4 X 4 X 2.6 µm is cleaved. This graphite flake is moved onto an atomic smooth surface of n-type silicon with a doping concentration of 1015cm-3. This surface is coated with Al electrode on the back of the film, at this point the electron transfer between the graphite and n-Si contacted surfaces will be done automatically to form a depletion layer and a Schottky barrier. In the third and the final step the top layer which is the graphite flake, is pressed using a conductive atomic force microscope tip which is coated with Au.

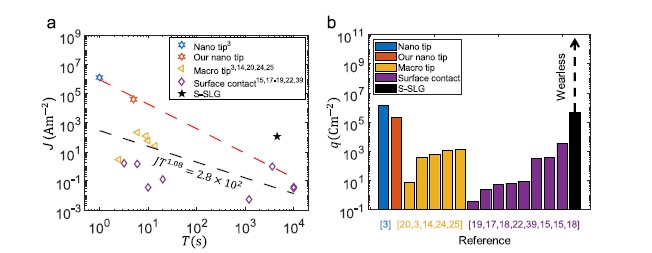

A comparative study is performed between the other reported S-G’s to have a broad understanding. In most of the S-G’s evident wear was observed due to the friction induced excitation. But on the researched material, after performing experiments the frictional co-efficient is found to be as low as 0.0039 – 0.0045. This is followed by another comparative study between Schottky superlubric generator and ordinary Schottky generator. This study is done by sliding an AFM Au-tip with a radius of curvature of 35nm and a normal force of 4.49 µN. It is observed that the normal S-G produce a pulse current unlike the stable output of the micro generator in discussion. The maximum current produced by the ordinary generator is also too low(15pA) compared to an approximate current density of 4 X 104 Am-2. Additionally, the life cycle of the general generator is observed to be at least two orders lower in magnitude. Which makes this combination of a micro generator far superior and highly efficient.

Fig2: Comparison of the Schottky superlubric generator (S-SLG) with reported Schottky generators

Followed by this experiment, scientists also performed a Quasi-static simulation of DLED mechanism to understand its behavior of the electronic dynamic transportation of continuous sliding contact in S-SLGs. This helps the researchers to understand and predict related properties derived from the simulation results. Though they may not be considered the most accurate. It is definitely helpful to draw conclusions and predict the material’s behavior. This is a new hope in this field of research which can show exponential progress with further research and collaboration. Having said that I feel that the likelihood of these micro generators to come into practical use in related fields is quite considerable in the near future.

Further information:

Huang, X., Xiang, X., Nie, J. et al. Microscale Schottky superlubric generator with high direct-current density and ultralong life. Nat Commun 12, 2268 (2021). https://doi.org/10.1038/s41467-021-22371-1

Abbreviations:

S-SLG: Schottky superlubric generator

S-Gs: Schottky generators

DLED: Depletion layer establishment and destruction

Leave a Reply

You must be logged in to post a comment.

The common sense towards having electrified trains should make sense but to go a step further where this article into electricity by friction seems to be heading and have an electrified pathway that could be applied over the existing road systems for vehicles should become the focus of innovation into the future of transportation?

Hello!

I could definitely see that as a possibility. I guess it requires proper infrastructure and technology which is good enough to yield profits after maintenance and initial costs of setting up such system. I believe we already do have such ideas in place. Especially by using piezoelectric materials, which generate electricity under pressure.

we have a highly conductive and abrasion resistant plating material vs. Au which could improve the life time of the devices.