Administration of the project

Close Examination of Frictional Wear on an Atomic Scale

Friction and wear have long been a focus of scientists, researchers, engineers, and industries around the world. The common goal is to maximize profits, however, the environmental impact becomes even more important. Wear and friction on machinery and its various components work against these factors, causing systems, machines, and components to work at less than peak efficiency. Ultimately, as wear and friction take their toll, efficiency decreases and costs increase, and replacements must be purchased.

A great deal of time and effort has gone into the study of friction in the sliding process. While our understanding of the many mechanisms that control the friction process is fairly comprehensive, we still do not fully understand which mechanisms are at play at a specific time under specific circumstances on one particular materials combination.

This gap in our knowledge is shrinking, thanks to researchers at TU Wien. Utilizing advanced large molecular dynamics computer simulations brings new light to the friction process at the microscopic level.

As a scientific tool, computer simulation was developed in nuclear physics and meteorology shortly after the end of World War II. Since that time computer simulations have expanded into a variety of fields, becoming an indispensable tool.

Successful simulations do more than simply compute numbers. They utilize a wide variety of techniques in order to make inferences from those numbers. The results of simulations are not automatically considered to be correct but must be tested to prove their validity. As computer simulations grow in depth and complexity, they are now powerful enough to simulate the wear and friction on real materials at an atomic level.

The atomic level is actually smaller than the nanoscale. The atomic scale means it we are dealing with atoms (makes sense), which are smaller than one nanometer.

The researchers examined the friction process in alloys of copper and nickel. Examining different ratios of the two metals, as well as varying mechanical loads, provided a comprehensive picture of the minute details occurring as the metals slide over each other. Details of the researchers’ results can be found in the article “Unraveling and Mapping the Mechanisms for Near-Surface Microstructure Evolution in CuNi Alloys under Sliding”.

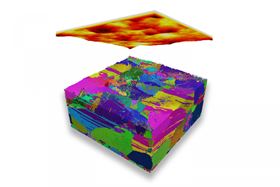

Stefan J. Eder, Manel Rodriguez Ripoll, Ulrike Cihak-Bayr, Daniele Dini, and Carsten Gachot undertook the task of examining the circumstances that encourage the process of plastic deformation, as well as surface damage. The researchers accomplished this by examining several different copper nickel alloys as they underwent sliding (which involves tens of millions of atoms) using molecular dynamic computer simulations. Grain size, shear, stresses, and twinning in the aggregate were all closely analyzed. The result was the creation of a deformation mechanism map for copper nickel alloys. The validity of the map was carefully verified for its accuracy by comparing the images produced by the simulation to those seen with an electron microscope. After intense verification, the simulation images proved to be valid.

When two metals slide against each other, we cannot see any changes with the human eye. However, multiple, complex changes and processes occur at the microscopic level. As the two metals slide against each other, their tiny grains, with a diameter no longer than a few micrometers, can be deformed, rotated, or shifted by the immense pressure. It is also possible that the microscopic grains are broken down into even smaller grains or grow larger as a result of the mechanical force occurring, or the resulting increased temperature.

Sliding of CuNi25 at 0.8 GPa colored according to the grain orientation (EBSD). TU Wien

Each metal has its own unique microstructure. The microstructure of a metal has a strong impact on the metal’s physical properties such as corrosion resistance, ductility, hardness, high/low temperature behavior, strength, toughness, or wear resistance. These processes taking place at the microscopic level determine the changes occurring to the metal on a larger scale.

While it is possible to examine the changes the grains have undergone with an electron microscope, it is not possible to study the timeline of the changes. Computer simulations now make this possible. Not only a timeline of the changes be mapped, but it is now possible to determine what causes each of the different changes at different points in time.

The field of tribology will be greatly enhanced by this new computer simulation technology. For years, researchers and scientists believed that the field could be improved with the use of computer simulations. The day has finally arrived when the simulations have reached a level of accuracy and computing power great enough that simulations are now useful to those studying tribology.

The team conducting this research are excited about what future computer simulations may bring to light. They hope to extend their research to analyze, understand, and improve any number of industrial processes at the atomic level.

More information: Stefan J Eder et al, Unraveling and Mapping the Mechanisms for Near-surface Microstructure Evolution in CuNi Alloys under Sliding, ACS Applied Materials & Interfaces (2020). DOI: 10.1021/acsami.0c09302

Be the first to comment