Administration of the project

Controlling Wettability and Liquid Repellence on Material Surfaces

Industries around the world would welcome new, improved engineered surfaces that included reversibly switching interfacial properties, including the ability to repel liquids and wettability. Wettability is the ability of a liquid to maintain contact with a solid surface. The degree of wettability is a result of a balance between adhesive (liquid to surface) and cohesive (liquid to liquid) forces. Wettability plays an important role in tribology as well, especially on the smaller scale.

However, materials with these properties are not easy to find, and very few exist. A group of researchers, led by Yue Liu from the Materials Science and Engineering Department and Chemistry and Molecular Engineering Department in China, recently generated a broad concept regarding the development of such engineered surfaces. The group specifically focused on developing metallic porous surfaces with controlled wettability.

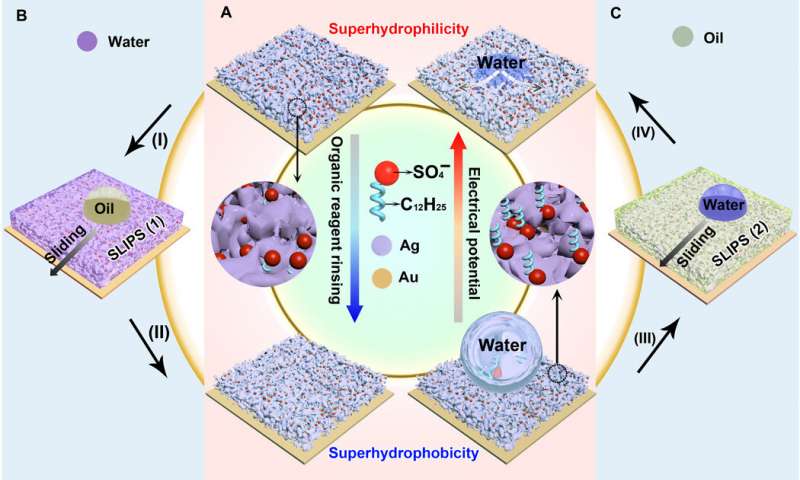

The team developed a single-step electrodeposition process to build porous metallic surfaces with both reversible wettability and liquid-repellent properties. Unlike previous processes, which attempted to use external stimuli such as pH values, light, or electrical potentials, this concept relies on the change in orientation of dodecyl sulfate ions, which are ionically bonded to a porous membrane. The membrane is superhydrophobic (extremely difficult to wet) when the dodecyl chains point out. The surface transitions to a superhydrophilic (attractive to water or other liquids) state when the dodecyl ions rotate and move into the pores of the membrane.

The surfaces created in this new process demonstrated adjustable wettability capabilities, which would capture various lubricants in the pores of the surface material. The result is the creation of a porous surface infused with liquid and customized for any desired liquid-repellent properties.

The researchers looked into various applications, including encryption, droplet transfer control, and water harvesting. Furthermore, the researchers were able to coat the porous silver membrane onto a copper mesh creating a liquid gate, which would allow various liquids to pass by when requested to do so.

Due to the low cost of the process, along with its easy adaptability, it is believed that the technique will have an impact across many different industries in a wide variety of applications. One unique application is the encryption of information.

The article “Electrodeposited Surfaces with Reversibly Switching Interfacial Properties” by Thammarasee Jeewandars provides an overview of how the process can be adapted for use in the field of encryption. First, a pencil connected to the negative pole of a power supply is used to drag a water droplet along the superhydrophobic surface, writing some kind of message. Immersing the porous membrane in water or exposing it to steam then reveals the previously hidden message. Finally, rinsing the membrane off with ethanol returns the surface to a superhydrophobic state. Consequently, the surface can be used repeatedly for different messages.

Along with encryption, the research team developed other applications for the technique. The applications include, but are not limited to, fog harvesting, droplet transfer, liquid-repellence, and oil/water separation. The team looked at the Namib Desert beetle (a beetle that is able survive some of the most arid conditions in the world by collecting water from the early morning fogs on its bumpy back surface) for inspiration. That inspiration led to the creation of patterned hydrophilic and hydrophobic stripes in order to create an excellent water repellent surface. Yue Liu and the other researchers involved in the project believe their method will have a strong influence in any number of fields, and be incorporated into a variety of applications.

For a more detailed explanation of the process, refer to the article “Electrodeposited Surfaces with Reversibly Switching Interfacial Properties” in Sciences Advances (advances.sciencemag.org/content/5/11/eaax0380/).

Be the first to comment