Computational Tribology

Predicting the size of wear particles

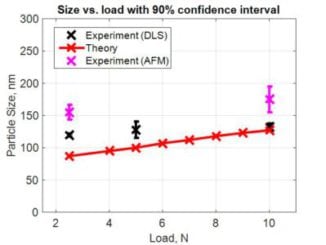

A wear process results in the generation of particles, of various size, shape, color and chemical composition. The reported size of wear particles varies from mm scale, which is typically attributed to severe wear, to […]