I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Abrasive Wear

Table of Contents

Definition:

Abrasive wear is the type of wear mechanism that results in the disintegration of the material on the surface due to the influence of the hard particle in contact with the surface. It also occurs when a hard surface or particles interacts or slides on the soft surface and causes material loss [1]. This is a type of the wear that occurs due to the loading of solid particle on the surface of the material which is having hardness that is equal or lesser compared to the loaded particle [2].

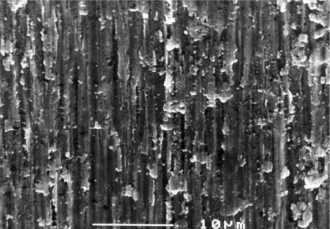

Fig-1 Figure illustrating the abrasive wear of Ti-6Al-4V alloy [3]

Abrasive wear mechanisms:

Abrasive wear can be caused in any condition on a surface in the presence of hard particles. for example, in case of the surface of the car tyre interacting on the road surface gets worn out very easily due to the interaction of softer tyre material with lower hardness compared to the road surface. The grooves can be found in abrasive wear tracks generated at the interface of the two similar metals experiencing sliding friction. There are also the formation of the wear particles or debris during this process that influence in further wearing on the materials surface [4]. The reason for the formation of the wear particles is due to the work hardening, phase transformation or the interaction of the third body at the interface [5].

The abrasive wear mechanisms was initially believed to be caused due to the cutting initiated by sharp edged objects or by wear grits. However, it is found in the microscopic analysis that there are many other indirect mechanisms involving in the initiation of the abrasive wear. That includes the particle removal by cutting, fracture, fatigue and grain formation. These four causes of abrasive wear mechanisms are explained below.

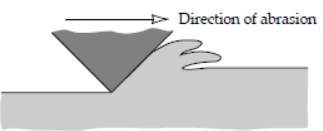

Abrasive wear due to micro-cutting:

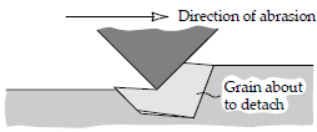

The first mechanism which represents the classic model of abrasive wear formation is the cutting where the sharp grit or asperity causes the cut on the softer material surface resulting in wear [6]. The worn-out material from the softer material surface is called the wear debris. This mechanism of micro-cutting is shown in the Fig-2.

Fig-2 Abrasive wear by cutting [7].

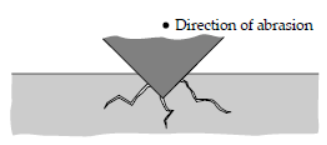

Abrasive wear due to fracture:

The wear caused due to the formation of brittle fracture generated by the crack initiated at the subsurface. There are mainly three modes of crack formation that includes vent cracks which propagates at 30degree to the surface, second mode is through localized fragmentation at the surface and the last is the deep median cracks [8]. The brittle fracture is formed due to the high loads acting on the sharp grits and due to the brittleness on the surface of the materials. This mechanism is illustrated in the Fig-3.

Fig-3 Abrasive wear by fracture [7].

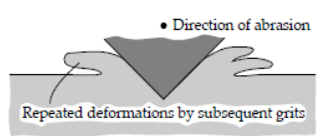

Abrasive wear due to fatigue:

When the grits on the surface causing the abrasive wear is causing the repeated strain on the surface of the metal causes the fatigue. These repeated strains influence the deformation by sideways material displacement that later results into a wear particle and causing the abrasive wear [9]. This mechanism is shown in the Fig-4.

Fig-4 Abrasive wear by fatigue [7].

Abrasive wear by grain pull out:

The grain pull out is a abrasive wear mechanism particularly found in case of ceramics materials. The grain pull out in ceramic materials is caused at the surfaces where the boundaries of grains at the surface is weaker and it is removed as the wear debris [10]. This mechanism is illustrated in the Fig-5.

Fig-5 Abrasive wear by grain pull-out [7].

Modes of Abrasive wear mechanism:

Based on the movement of the wear debris formed during the abrasive wear outside the worn surface, the abrasive wear can be divided into two groups namely two body abrasive wear and three body abrasive wear.

Two-body abrasive wear:

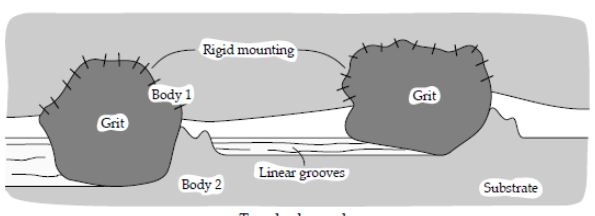

In this mode the wear occurs due to the removal of the materials on the surface by sharp grits or hard particles. This mode can be simply explained by an example of material removal by the sand paper on the opposite surface. The material displacement in this mode takes place due to the cutting or ploughing operations [11]. The two-body abrasive wear mode is illustrated in the Fig-6.

Fig-6 Abrasive wear by two-body wear mode [7].

Three-body abrasive wear:

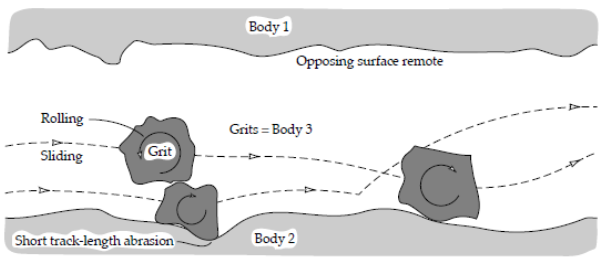

In this mode the wear occurs very slowly compared to the two-body wear mode due to the non constrained motions of the grits at the interface of the surface causing the wear. The grits freely roll and slide at the interface, the properties like hardness of the surface that forces the grits on to the surface is an important feature determining the wear [12]. The three body abrasive wear is shown in the Fig-7.

Fig-7 Abrasive wear by three-body wear mode [7].

Abrasive wear research:

GK Nathan et.al., [13] studied the various factors influencing the abrasive wear in metals and the conditions such as applied load, length of abrasive path, velocity of the abrasive surface, types of abrasive particle, temperature and absolute humidity of the environment etc. are the influencing parameters of the abrasive wear. In a study conducted by H. Unal et.al., [14] on the abrasive wear behaviours of the polymeric materials found that the wear rate increases linearly with increasing the duration distance of the wear. A model on demonstrating the abrasive wear resistance of the multiphase materials was shown by N. Axen et.al., [15] this model helps in clarifying the roles of the matrix and the reinforcing phase in a composite that resists the wear of the multiphase materials.

Reference:

[1] Bhushan B. Principles and Applicaion of Tribology. New York: A Wiley-Interscience Publication; 1999.

[2] Kato K. Abrasive Wear of Metals. Tribology International. 1997:333-8.

[3] Redmore, E., Li, X. and Dong, H., 2019. Tribological performance of surface engineered low-cost beta titanium alloy. Wear, 426, pp.952-960.

[4] Rigney DA. Comments on Sliding Wear of Metals. 1997;30.

[5] Moore MA. A Review of Two-Body Abrasive Wear. 1974;27.

[6] T. Kayaba, The Latest Investigations of Wear by the Microscopic Observations, JSLE Transactions, Vol. 29, 1984, pp. 9-14.

[7] Stachowiak, G.W. and Batchelor, A.W., 2013. Engineering tribology. Butterworth-heinemann.

[8] K. Phillips, Study of the Free Abrasive Grinding of Glass and Fused Silica, Ph.D. Thesis, University of Sussex, United Kingdom, 1975.

[9] O. Vingsbo and S. Hogmark, Wear of Steels, ASM Materials Science Seminar on Fundamentals of Friction andWear of Materials, 4-5 October 1980, Pittsburg, Pennsylvania, editor: D.A. Rigney, Metals Park, Ohio, Publ.ASM, 1981, pp. 373-408.

[10] M.V. Swain, Microscopic Observations of Abrasive Wear of Polycrystalline Alumina, Wear, Vol. 35, 1975, pp. 185-189.

[11] N. Emori, T. Sasada and M. Oike, Effect of Material Combination in Rubbing Parts on Three Body Abrasive Wear, JSLE Transactions, Vol. 30, 1985, pp. 53-59.

[12] T. Sasada, M. Oike and N. Emori, The Effects of Abrasive Grain Size on the Transition Between Abrasive and Adhesive Wear, Wear, Vol. 97, 1984, pp. 291-302.

[13] Nathan, G.K. and Jones, W.J.D., 1966. The empirical relationship between abrasive wear and the applied conditions. Wear, 9(4), pp.300-309.

[14] Unal, H., Sen, U. and Mimaroglu, A., 2005. Abrasive wear behaviour of polymeric materials. Materials & Design, 26(8), pp.705-710.

[15] Axen, N. and Jacobson, S., 1994. A model for the abrasive wear resistance of multiphase materials. Wear, 174(1-2), pp.187-199.

Leave a Reply

You must be logged in to post a comment.

send me tittle thesis around tribology