I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Elastohydrodynamic Lubrication Regime

Table of Contents

Introduction

The lubrication regime that occurs due to the elastic deformation of the lubricated contacts is the elastohydrodynamic lubrication regime. This lubrication regime is important for all lubrication regimes to understand because of its application in various mechanical components such as roller bearings, cam-tappet system, flexible seals, and bio-medical applications of human synovial joints [1].

Definition

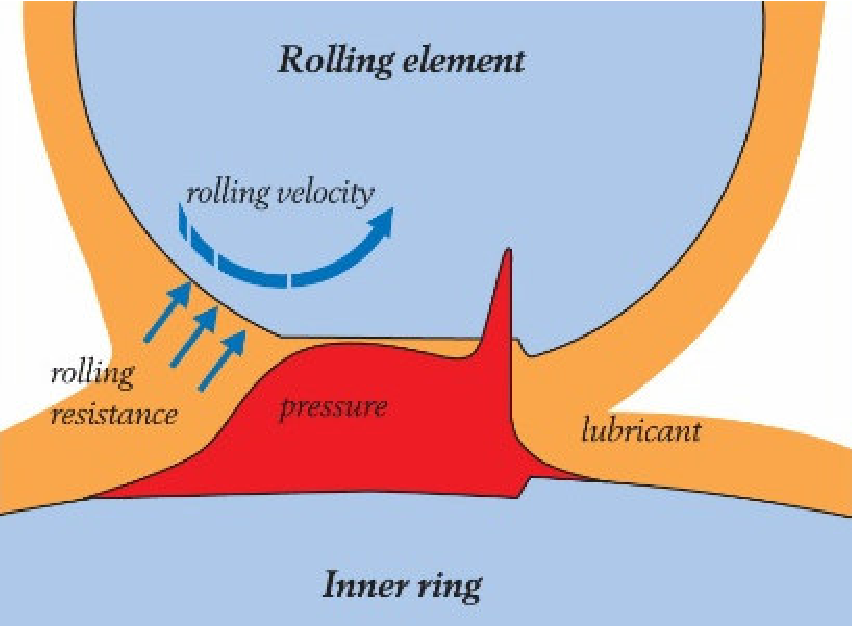

Elastohydrodynamic lubrication (EHL) occurs in non-conformal lubricated contacts where the load per unit area is high compared to the stiffness of the material and the contacting surfaces. The schematic representation of the EHL is shown in the Fig-1 This is possible when the contacts do not fit well together due to the limited contact area and the high elastic deformation at the surface. The surfaces in the contact interface may roll, spin or slide against each other which tends to the lubricant to be dragged into the converging gap of the contacts due to the shear stress exerted on the lubricant from the surface [2].

Fig-1 Schematic representation of the roller bearing elements [3]

Types of EHL

The EHL can be classified into two types they are Hard EHL and Soft EHL [2].

Hard EHL: Hard EHL contact occurs mainly in metallic contacts where the materials have a high elastic modulus. The EHL can be distinguished as soft or hard mainly by the pressure on the lubricant viscosity which plays an important role in the elastic deformation of the bodies. In the case of the hard EHL contacts, the maximum pressure can reach 3-4 GPa and the minimum film thickness would be in the range of 0.1-1 μm. This type of lubrication is seen mainly in the applications such as gears, rolling bearings, cams, rail wheel contacts, etc.

Soft EHL: Soft EHL occurs in the case of the softer materials with low elastic modulus and the elastic deformations are larger when the applied loads are lighter. The maximum pressure, in this case, is 1MPa, because of the lower pressure in the contacts interface it does not affect the viscosity of the lubricant. Since the pressure–viscosity coefficient does not vary much it would not be considered in the calculation of the minimum film thickness. The practical applications of this type of EHL contacts include seals, tiers, and other machinery with rubber or plastic-based lubricated contacts.

Physical properties

Film thickness-pressure profile:

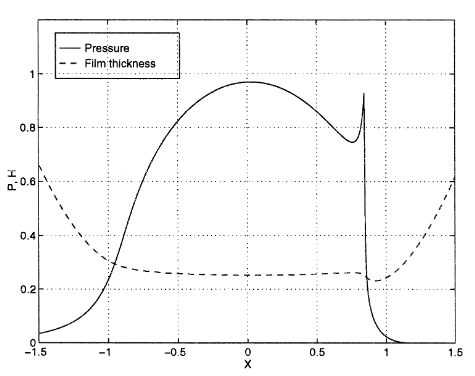

In both cases of the hard and soft EHL contacts, there is a formation of the coherent fluid film which helps in preventing the asperity interaction at the contact interfaces. This shows that the shearing of the lubricant is one of the major contributions to resisting the friction at the contacts during the motion. The pressure distribution and the lubricating film thickness of the EHL are very important to be studied to implement in different applications. Fig-2 shows the film thickness profile and the pressure distribution in the EHL contacts. Here we can see that the central part of the curve has uniformity in film thickness and the press distribution is Hertzian except the inlet and outlet. At the outlet there is a pressure spike which decreases as the speed or viscosity of the lubricant is decreased [4].

Fig-2 Film thickness profile and pressure distribution in an EHL contact [2]

Frictional properties of EHL:

The friction prediction in the EHL regime is one of the challenging issues, the understanding of the change in the frictional properties under EHL is dependent on studying the rheological properties of the lubricant. However, in comparison to the boundary lubricated regimes the COF values at the EHL are considerably less which depends on the properties of the lubricant layers such as the chemistry of the lubricant, additives in the lubricant, and the surface system. Another important aspect that influences friction is the surface topography at the contact interface. The greatest influence of the surface topography can be seen at the transition region from the boundary to full film lubrication regimes.

Starvation

Starvation is the condition in which the increase in the oil supply at the contact would increase the film thickness. The film thickness in the starved EHL contact depends on the contact geometry, speed, physical properties of the lubricant, and the lubricant supply at the contact. When the contact is fully flooded then the pressure build takes relatively far upstream with a non-zero pressure gradient. If the inlet is not fully filled, then the two layers of the oil merge to form the meniscus at the inlet of the contact, which two layers of the oil merge to form the pressure at that point. Thus, the reduction in the lubricant feed will reduce the film thickness and the shape of the pressure distribution in the contact [1].

Difference between fully flooded EHL and starved EHL

The schematic representation of the film thickness and the pressure distribution curves for both the fully flooded and starved EHL is shown in the Fig-3. Here the difference in the pressure spike can be seen where there is no pressure spike at the starved EHL. However, in the case of the fully flooded EHL a clear pressure spike is observed.

Fig-3 Film thickness profile and pressure distribution in an EHL contact [5]

Research on EHL

The study of the EHL in various aspects considering the properties of the lubricants, varying the type of lubricants, and the physical parameters such as the pressure, viscosity, temperature, etc is important. These studies help in improving the efficiency of the various mechanical components operating in the EHL regime. Erik Hoglund has studied the influence of lubricant properties on the EHL using oils of different origins i.e., mineral, vegetable, and synthetic oils. Different oils have shown different results where the mineral oil has the highest values of pressure-viscosity coefficients and exhibits high density with an increase in pressure whereas vegetable oil has exhibited low density with an increase in pressure. These type of studies finds the application of different oils to improve the desirable properties at the EHL contact in the required components [6]. Also, researchers have studied the effect of EHL at different contacts and have developed models to study their effect based on the contact at the interface [7].

EHL Film Thickness Calculator (Central and Minimum): Elliptical (Point) Contact

References

[4] I. Newton, Philosophiae Naturalis Principia Mathematica, Impri- matur S. Pepys, Regiae Societatis Praeses, 5 Julii 1686, 4to Londini, 1687

Be the first to comment