Administration of the project

Four Ball Tester

Table of Contents

What is a Four Ball Tester?

Oil lubrication and lubrication technologies are essential in reducing friction and wear losses in machines. The key in efficiency of the frictional system is a lubricant (grease, oil, solid lubricants). Four Ball Tester, also known as Shell four ball tester, is used to characterize lubricants properties, such as wear prevention (WP), extreme pressure (EP) and frictional behavior (various testing standards are listed below).

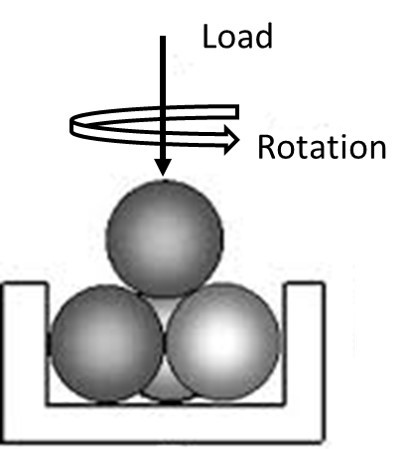

The tester consists of four balls in the configuration of an equilateral tetrahedron, as shown in the figure below. The upper ball rotates and is in contact against the lower three balls, which are held in a fixed position.

Four Ball Extreme Pressure Test

When the extreme pressure properties of a lubricant are tested, the ability of a lubricant to function under extreme pressure conditions is determined. The test starts at ‘low’ loads – loads at which the lubricant functions well, a proper lubricant film is developed and seizure is not detected. The load is gradually increased according to the test standard until the lubrication fails, meaning that the lubricant film can no longer separate the surfaces and there is surface to surface contact. As a last step, the load is increased until catastrophic failure occurs. This final failure is termed ‘welding’ and is characterized by increased noise level, sharp changes of the friction signal, etc. Based on the performance of a lubricant in this test, different formulations can be developed.

Four Ball Wear Test

Four ball test can also be used to measure the performance of the lubricant with respect to wear. During the test the upper ball is rotated against the rest of the balls that are fixed. The load is performed at fixed conditions (load, temperature, speed, etc.), unlike the extreme pressure test. After the test, the wear scar measurements are performed using for example optical profilometry and can be used to judge the performance of a lubricant with respect to wear. Friction force is also measured during this test and therefore, can also be analyzed.

Lubricant testing procedure

Here is a video of four ball tester operation:

Testing standards for four ball tests

The following testing standards are based on four-ball tester use:

•ASTM D2783: EP Test for lubricating fluids (ASTM D2596 for grease)

•IP 239: EP and AW tests for lubricants

•DIN 51350-02: Extreme pressure properties test for liquid lubricants

•ASTM D4172: WP tests for lubricating fluids (ASTM D2266 for greases)

•ASTM D5183: Coefficient of friction of lubricants

•DIN51350-03: Wear test for liquid lubricants

References

- [1] Rapid selection of environmentally friendly layered alkaline-earth metal phosphates as solid lubricants using crystallographic data,, Xiaosheng Zhang,Wenxing Niu,Yingjing Dai,Hong Xu &Jinxiang Dong, https://doi.org/10.1038/s41598-018-34478-5

Be the first to comment