Administration of the project

History of Journal Bearings

Table of Contents

What is a Journal Bearing?

Journal Bearing is one of the most common and the simplest type of bearings and is a type of plain bearing. Essentially, a journal bearing is a shaft that rotates in the whole. A good discussion on the engineering principles of journal bearings can be found in the following video:

Despite its simplicity, journal bearings have an extensive and interesting history which we will try to outline in this short article. For a more thorough discussion on the history of journal bearings, we highly recommend a paper by Hannon W.M. and Braun M.J. [1] and a History of Tribology written by Dawson [2]

History of Journal Bearings

Bearings gained popularity during the industrial revolution in the 19th century, but their history dates back to 1607 when Zonka published a paper on existing machines and their applications [1]. At approximately the same time, the concept of roughness was invented.

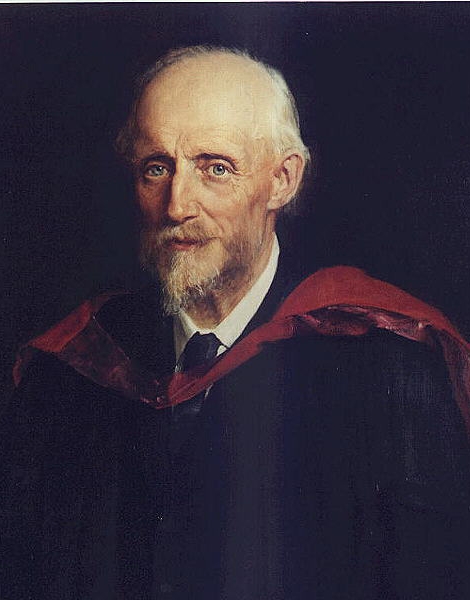

Some people believe that it was Gustav Hirn who was the father of plain bearings [3]. He showed that in the absence of lubrication, friction occurs according to the Coulomb’s law. He then showed that if you use grease and a slightly loaded bearing, the coefficient of friction will increase with increasing shaft speed. Hirn also proved that the coefficient of friction with an average load in a lubricated bearing is proportional to the square root of speed, load, and journal area.

In 1907, Robert Henry Thurston calculated the coefficient of friction for most of the systems, including a plain bearing. Among the plethora of information on friction, Thurston pointed that the coefficient of friction passes through a minimum as the load increases. Now, this discovery is recognized as the starting point for the transition from hydrodynamic to elastohydrodynamic lubrication.

It is also worth telling here the influence of Nikolai Petrov, who in 1883 took the first step towards studying the effects of friction associated with lubrication in the form of a liquid film [4]. In his work, he analyzed the experimental work of Hirn and demonstrated the importance of frictional effects in films. In total, Petrov has carried out over 600 experiments that show carefully measured values of friction. As a result of this work, Petrov introduced a relation which is now referred to as Petrov’s law

In parallel with the discoveries of Petrov, the English mechanical engineer Beauchamp Tower made independent discoveries in the same area. In 1883, he published reports showing pressure measurements of a liquid film in a slip bearing. He accidentally discovered hydrodynamic pressure. He also found that the local pressure of the liquid film is higher than the average pressure. Tower concluded that the pressure is constantly changing in a circumferential direction. In addition, he found that due to the vertical load, the pressure distribution becomes highest at the bottom of the bearing and drops to atmospheric pressure at the top. In his next works, Tower investigated the pressure distribution in the sliding bearing. He found that the integral of the circumferential pressures of the bearing gives the load capacity equal to the applied load. He then published two more papers, but they were overshadowed by the theory of liquid film, which was developed by Osborne Reynolds in 1886.

In his famous work, Reynolds presented results that indicate that the inclination between two rigid bodies determines the load-carrying capacity of a plain bearing. He also studied the effects of the tangential motion of a parallel plate relative to a fixed plate. Ultimately, by applying the method of expressing stress in a viscous fluid, Reynolds simplified the Navier-Stokes equations (while making several fundamental assumptions). These simplified equations were then solved for axial and circumferential velocities in terms of pressure gradients, film thickness, and journal surface velocity. These velocities were then introduced into the continuity equation. When integrated over the liquid film thickness, what is known now to be the “Reynolds equation” was obtained:

(1)

To find a solution for a partial plain bearing, Reynolds applied trigonometric series. Then the results obtained were compared with the experiments of Tower. Reynolds’ work truly expanded the understanding of how plain bearings work and the influence of his work on comprehension journal bearings is hard to overestimate.

We note that although the study of liquid film bearings did not begin with Reynolds’ experiments, he was the first to propose a differential equation. Over time, researchers began to make changes to it. The new models have led to the addition of energy, variable properties, cavitation, turbulence, inertia, and coupling to the rotor dynamics equations to the equation.

The Energy Equation and Rise of the Thermal Wedge

When comparing the results obtained from experiments and theory, it becomes apparent that the thermal environment of the bearing will influence density, dynamic viscosity, conductivity, and specific heat and, consequently, influence pressure. For example, Fogg [5] made an unexpected discovery in 1946 by observing the increase in load-bearing capacity of a parallel plate thrust bearing. To explain this, he postulated the formation of a thermal wedge of the liquid film as the cause of the loading. The geometric wedge arises from the eccentricity of the shaft, which causes a change in the speed of the fluid, which in turn must be balanced by pressure forces. A thermal wedge occurs due to density changes resulting from temperature fluctuations in all three directions.

Cope [6] in 1949 combined the classical Reynolds equations with the equations of state for density and viscosity. Cope’s energy analysis began by linking friction heat dissipation to the amount contained in the lubricant. To obtain the boundary conditions for the energy equation, Cope assumed that heat does not travel to the shaft and sleeve. He stated that the density of a gas is directly proportional to pressure and inversely proportional to temperature. In this context, it should also be mentioned that at very high pressures, the oil can become “solid”, leading to a three-component solid lubrication situation. Cope stated that Fogg’s thermal wedge was “fully justified,” and mathematically expressed this in equations.

Other Forms of the Reynolds Equation

After the coupling of the fluid energy equation with the Reynolds equation became common in engineering, some authors wanted to improve the classical Reynolds equation to include variable properties and their effects that could reflect both geometric and thermal wedges.

Dawson[7] was the first to propose the generalized Reynolds equation. It had to internally account for both wedge and thermal effects. This generalized form contains several functions that represent integrals over the film thickness of density and dynamic viscosity, as well as integrals over the entire film. Since the late 1960s, several other authors have also proposed various modifications of the Dawson equation.

References

- [1] Hannon W.M., Braun M.J. (2013) Hydrodynamic Journal Bearing History. In: Wang Q.J., Chung YW. (eds) Encyclopedia of Tribology. Springer, Boston, MA. https://doi.org/10.1007/978-0-387-92897-5_42

- [2] D. Dowson, The History of Tribology (Longman Group, London, 1979)

- [3] G. Hirn, Sur les principaux phe´nome`nes qui pre´sentent les frottements me´dias. Bull. Soc. Ind. Mulhouse 26, 188–277 (1854)

- [4] N.P. Petroff, Friction in machines and the effects of the lubricant. Inzh. J. St. Petersburg 5, 189–194 (1883)

- [5] A. Fogg, Fluid film lubrication of parallel surface thrust bearings. Proc. Inst. Mech. Eng. 155, 49–67 (1946)

- [6] W.F. Cope, The hydrodynamical theory of film lubrication. Proc. R. Soc. Lond. A Math. Phys. Sci. 197(1049), 201–217 (1949)

- [7] D. Dowson, A generalized Reynolds equation for fluid-film lubrication. Int. J. Mech. Sci. 4, 159–164 (1962)

Be the first to comment