I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Surface Roughness

Table of Contents

Definition

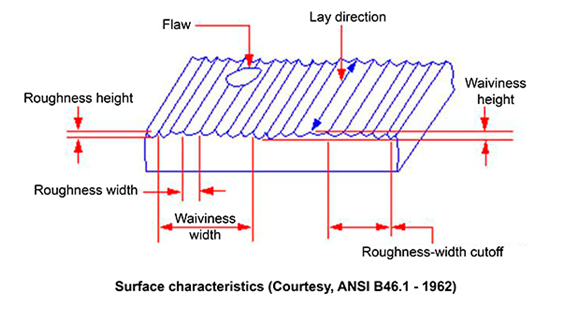

Surface roughness is defined as the irregularities which are inherent in the production process (e.g., cutting tool or abrasive grit). It may be the result of vibrations, chatter, or work deflections and strains in the material. In surface metrology, roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. [1] In tribology, rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces. Roughness is often a good predictor of the performance of a mechanical component, since irregularities on the surface may form nucleation sites for cracks or corrosion. On the other hand, roughness may promote adhesion. [2] Fig-1 shows the surface roughness with proper labeling.

Fig-1 Surface Roughness Profile with labeling [4]

Causes for surface roughness

When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3]

Surface Roughness Parameters

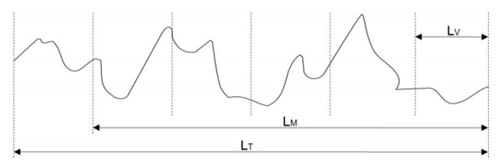

Traversing Length:

It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length.

Assessment Length:

It is the length over which the surface is acquired and assessed. It is denoted by LM

Sampling Length:

It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter.

Fig-2 Indication of the Length Parameters in the Surface Roughness profile.

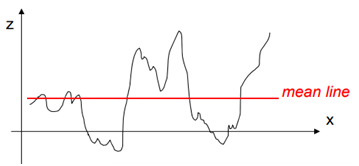

Mean Line of the profile:

It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile.

Fig-3 Indication of the mean line in the Roughness profile.

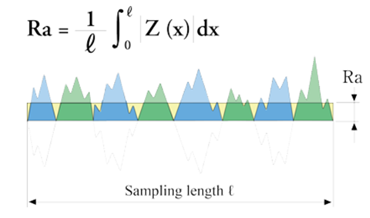

Arithmetic mean deviation (Ra):

Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5]

Fig-4 Indication of the Ra on the surface roughness profile.

Root mean square deviation (Rq):

Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5]

Fig-5 Indication of the Rq on the surface roughness profile. [6]

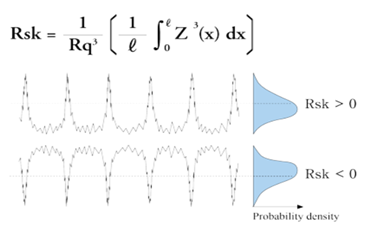

Skewness (Rsk) :

The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5]

Fig-6 Indication of the Rsk on the surface roughness profile. [6]

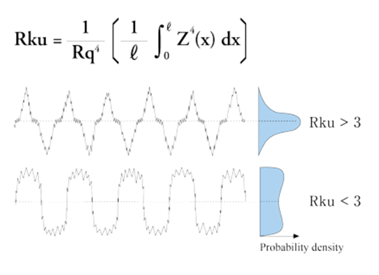

Kurtosis (Rku):

The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5]

Fig-7 Indication of the Rku on the surface roughness profile [6]

Reference

[1] https://guide.digitalsurf.com/en/guide.html

[2] https://en.wikipedia.org/wiki/Surface_roughness

[4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135

[5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall.

[6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Be the first to comment