The article is written by Riya Veluri, an editorial team member of Industrial Lubricants. After her graduation, Riya works as a website developer & SEO specialist in Lubrication & Tribology Industry & writes technical articles on Lubricants, Lubrication, Reliability & sustainability.

Viscosity Index

Table of Contents

What is viscosity index?

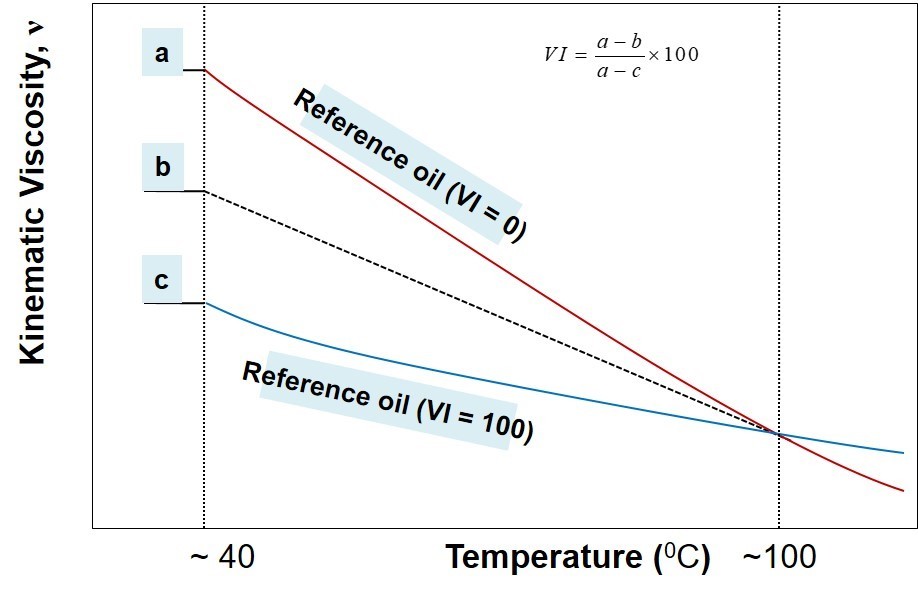

The viscosity index (VI) is an arbitrary, unitless measure of a fluid’s viscosity change relative to a temperature change. We can say that the it is the dimensionless number that shows how the temperature change can affect viscosity of an oil (engine oil and automatic gear oils, and power-steering fluids). The higher the VI, the smaller the change in fluid viscosity for a given change in temperature and vice versa. Thus, a fluid with a low viscosity index will experience a relatively large swing in viscosity as temperature changes. High-VI liquids, in contrast, are less affected by temperature changes. Viscosity Index was measured by a scale of 0 to 100; however, modern science of lubrication has led to the development of oils with very high VI. The best oils with the highest VI are stable and do not vary greatly in viscosity over a wide temperature range. In turn, this means consistent, high performance in the machine.

Calculate Viscosity Index

Standard ASTM D2270 Calculates Viscosity Index by Measuring the Kinetic Viscosity of Liquids at 40° and 100°C and ASTM D567 Method for Calculating Viscosity Index from Viscosity at 100ºF and 210ºF.

Normally, all things being equal, highly refined mineral oils with few contaminants have high VIs and Synthetic oils generally have a higher VI than mineral oils. Below you will find a simple VI calculator.

ASTM D2270 and ISO 2909:

Oil viscosity (see ASTM D445) usually decreases with increasing temperature. If this reduction is significant, the system may not be sufficiently lubricated over the entire operating temperature range. The viscosity index describes this change – a high viscosity index indicates a slight viscosity change with increase in temperature compared to a low viscosity index.

- The standard covers procedures for calculating the viscosity index of petroleum products, such as lubricating oils, and related materials by their kinetic viscosities at 40°C and 100°C.

- The standard does not apply to petroleum products with a kinematic viscosity less than 2.0 mm2/s at 100 °C. This practice applies to that petroleum or lubricating products whose kinetic viscosity is between 2mm2/s and 70 mm2/s at 100°C. Equations are already provided for calculation of viscosity index for products like petroleum with kinematic viscosity above 70mm2/s at 100 °C.

- Values stated in SI units are considered standard. No other units are there for measurement in this standard.

- The values stated in SI units are to be regarded as the standard. For user reference, 1 mm2/s = 10-6m 2/s = 1 cSt.

ASTM D567 Method for Calculation of Viscosity Index from Viscosity at 100ºF and 210ºF.

The viscosity of oil usually decreases as the temperature increases. Viscosity index means that it measures the change in viscosity with temperature – a high viscosity index indicates a small viscosity change of a petroleum product with changes in temperature. This is the method that determines the viscosity index of lubricating oils. This method is considered obsolete by ASTM and replaced by ASTM D2270.

Viscosity Index Calculator

Here we are discussing the rule of calculating the viscosity Index.

L = kinematic viscosity of an oil at 40 °C of 0 viscosity index having the same kinematic viscosity at 100 °C as the oil whose viscosity index needs to be calculated, mm2 /s,

Y = kinematic viscosity at 100 °C of the petroleum product whose viscosity index needs to be calculated, mm2 /s.

H = kinematic viscosity of an oil at 40 °C of 100 viscosity index having the same kinematic viscosity at 100 °C as the oil whose viscosity index needs to be calculated, mm2 /s.

U = kinematic viscosity at 40 °C of the lubricant or petroleum product whose viscosity index needs to be calculated, mm2 /s.

The viscosity index can be calculated using the following formula:

ASTM D2270 table to get the L & H values for the calculations.

Here is a simple VI calculator to calculate viscosity index from the temperatures at 40°C and 100°C:

This calculator allows calculating kinematic viscosity at 100°C from the known VI and kinematic viscosity of the oil at 40°C:

This calculator allows calculating kinematic viscosity at 40°C from the known VI and kinematic viscosity of the oil at 100°C:

The common equation used to calculate the viscosity by interpolation between two reference points is with the Ubbelohde-Walther equation, which is adopted in ASTM D341. Here is a simple calculator to interpolate viscosity:

VI modifiers:

VI modifiers are normally used in multi-grade engine oils, gear oils and automatic transmission fluids, power steering fluids, hydraulic fluids and greases. Widely used materials are, for example, olefin copolymers (OCP), polyalkyl methacrylates (PAMA), poly isobutylene (PIB), styrene block polymers, methylmethacrylate (MMA), polybutadiene rubber (PBR), cis-polyisoprene. (of a synthetic rubber), polyvinyl palmitate, polyvinyl caprylate, copolymers of vinyl palmitate with vinyl acetate, and various other materials used as viscosity index modifiers in a variety of petroleum oils.

Below is the table of viscosity indexes of different petroleum products & fluids for ref:

| Oil / fluid types | VI |

|---|---|

| Mineral oil | 95 – 105 |

| Multi-grade oil | 140 – 200 |

| PAO oil | 135 – 160 |

| Ester | 140 – 190 |

| Vegetable oil | 195 – 210 |

| Glycol | 200 – 220 |

| Silicone oil | 205 – 400 |

Classification:

The VI scale was established by the Society of Automotive Engineers (SAE). The arbitrarily chosen temperatures for reference are 100 and 210 °F (38 and 99 °C). The scale was initially interpolated between 0 for naphthenic Texas Gulf crude and 100 for paraffinic Pennsylvania crude. Since the scale’s inception, better oils have also been produced, making VI over 100 (see below).

VI-improving additives and high-quality base oils are widely used nowadays, allowing VI to be achieved over a value of 100. The viscosity index of synthetic oils ranges from 80 to over 400.

Normally when we are talking about the synthetic oils, then there are normally two types of synthetic oil available for widely used in different critical & high temperature applications.

- PAO Based synthetic Oil (Polyalphaolefin)

- PAG based synthetic oil (Polyalkylene Glycol).

Study shows that PAO based synthetic oils have better viscosity index compare to Group – i, group – ii or group – iii oils (Without addition of any index significantly better than PAO-based lubricants of the same viscosity grade.

| VI | Classification |

| Under 35 | Low |

| 35 to 80 | Medium |

| 80 to 110 | High |

| Above 110 | Very high |

Conclusions:

The viscosity index is an essential parameter indicating the flow properties related to the temperature of the oil. Selection of oil for a specific application without considering its VI, e.g. cause premature wear and costly machinery damage. As we have already discussed that normally in synthetic oil, Viscosity index is greater than the any kind of mineral oil. So, In critical applications or high temperature applications synthetic oil or grease is preferred rather than mineral oil based lubricants.

References:

- BLAIR, G. Viscosity of Liquids and Colloidal Solutions. Nature 156, 147–148 (1945). https://doi.org/10.1038/156147a0

- http://ppapco.ir/wp-content/uploads/2019/07/ASTM-D2270-2016.pdf

- https://wiki.anton-paar.com/en/viscosity-index/

- https://en.wikipedia.org/wiki/Viscosity_index

Leave a Reply

You must be logged in to post a comment.

Is there a way to calculate the Viscosity at -40C for Dexron 75W-90 pour point is -57C

Hello Bryan! You can use the Ubbelohde-Walther calculator. To use it you would need viscosity at 2 different temperatures. I hope this helps!

Hi there!

Great article but it didn’t explain what’s the difference (if any) between

ASTM D2270 and ISO 2909, as we could see on many engine oil manufacturers technical sheets. Could you please explain that?

Best of luck and keep up the good work you are doing!

Chris

Hi,

Could you please tell me PAG base oil is good for a slow RPM gearbox that is lubricated by splash lubrication?