I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

What is Lubrication?

Table of Contents

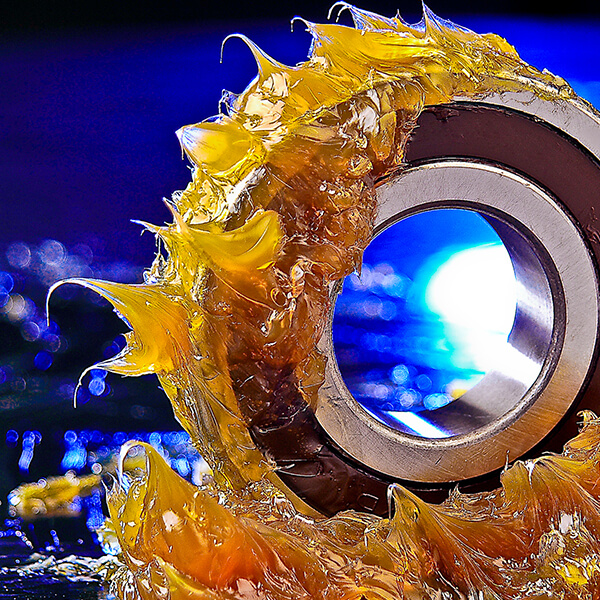

Lubrication can be defined as the application of some materials between two objects moving relative to each other to allow smooth operation as much as necessary. Either oil or grease is used for rolling bearings to prevent noise, wear and tear, and heat from being generated from their rolling and sliding movements, and in some special cases, solid lubricants are occasionally used. The amounts and kinds of lubricants for rolling bearings are determined depending on operation speed, temperature, and surrounding condition, and so on. Because lubricants have spent their service-life or polluted with foreign materials, they cannot serve their function well hence they have to be periodically replaced or oiled.

Fig-1 Lubrication

Purpose of Lubrication

The main purposes of lubrication are the following:

- Forming a lubrication film on the interface between two parts reducing the amount of loading and hence extending its service life.

- To enhance the favourable driving characteristics, such as low noise or friction.

- To prevent overheating of bearings and to prevent lubricants deterioration by radiating the generated heat to outside. It works particularly well if the circulation lubrication method is adopted.

- To prevent foreign material penetration, rust, and corrosion.

Lubricant

In all types of machines, the surfaces of moving or sliding or rolling parts rub against each other. Due to the mutual rubbing of one part against another, a resistance is offered to their movement. This resistance is known as friction. It causes a lot of wear and tear of surfaces of moving parts. Any substance introduced between two moving/sliding surfaces with a view to reduce the friction (or frictional resistance) between them, is known as a lubricant. The main purpose of a lubricant is to keep the moving/sliding surfaces apart, so that friction and consequent destruction of material is minimized. The process of reducing friction between moving/sliding surfaces, by the introduction of lubricants in between them, is called lubrication.

Function of Lubrication

- It reduces wear and tear of the surfaces by avoiding direct metal to metal contact between the rubbing surfaces, i.e., by introducing lubricants between the two surfaces.

- It reduces expansion of metal due to frictional heat and destruction of material.

- It acts as coolant of metal due to heat transfer media.

- It avoids unsmooth relative motion.

- It reduces maintenance cost.

- It also reduces power loss in internal combustion engines.

Mechanisms of Lubrication

- Thick-Film lubrication

In this, moving/sliding surfaces are separated from each other by a thick film of fluid, so that direct surface to surface contact and welding of junctions does not occur. The lubricant film covers/fills the irregularities of moving/sliding surfaces and forms a thick layer between them, so that there is no direct contact between the material surfaces. This consequently reduces friction. The lubricant chosen should have the minimum viscosity (to reduce the internal resistance between the particles of the lubricant) under working conditions and at the same time, it should remain in place and separate the surfaces. Hydrocarbon oils (mineral oils which are lower molecular weight hydrocarbons with about 12 to 50 carbon atoms) are considered to be satisfactory lubricants for thick-film lubrication. In order to maintain the viscosity of the oil in all seasons of year, ordinary hydrocarbon lubricants are blended with selected long chain polymers.

Fig-2 Thick film lubrication

- Thin film Lubrication

This type of lubrication is preferred where a continuous film of lubricant cannot persist. In such cases, the clearance space between the moving/sliding surfaces is lubricated by such a material which can get adsorbed on both the metallic surfaces by either physical or chemical forces. This adsorbed film helps to keep the metal surfaces away from each other at least up to the height of the peaks present on the surface. Vegetable and animal oils and their soaps can be used in this type of lubrication because they can get either physically adsorbed or chemically react into the metal surface to form a thin film of metallic soap which can act as lubricant. Although these oils have good oiliness, they suffer from the disadvantage that they will break down at high temperatures. On the other hand, mineral oils are thermally stable and by adding vegetable/animal oils to them, their oiliness can be brought up. Graphite and molybdenum disulphide are also popular choices for thin film lubrication.

Fig-3 Thin film lubrication

- Extreme Pressure Lubrication

When the moving/sliding surfaces are under very high pressure and speed, high local temperatures develop, liquid lubricants fail and may decompose and even vaporize. To meet these extreme pressure conditions, special additives are added to minerals oils. These are called extreme pressure (EP) additives. These additives form a film capable of withstanding very high loads and high temperatures on metal surfaces. Important additives are organic compounds having active radicals or groups such as chlorine (as in chlorinated esters), sulphur (as in sulphurized oils) or phosphorus (as in tricresylphosphate). These compounds, at sufficiently elevated temperatures, react with metallic surfaces to form metallic chlorides, sulphides or phosphides.

Fig-4 Extreme pressure lubrication

Classification of Lubricants

Lubricants are classified on the basis of their physical state, as follows;

- Liquid lubricants or Lubricating Oils,

- Semi-solid lubricants or Greases and

- Solid lubricants.

Liquid lubricants or Lubricating Oils

Lubricating oils also known as liquid lubricants and further classified into three categories: Animal and Vegetables oils, Mineral or Petroleum oils and Blended oils.

- Animal and Vegetables oils: Animal oils are extracted from the crude fat and vegetables oils such as cotton seed oil and caster oils. These oils possess good oiliness and hence they can stick on metal surfaces effectively even under elevated temperatures and heavy loads. But they suffer from the disadvantages that they are costly, undergo easy oxidation leading to gummy products and hydrolyses easily on contact with moist air or water. Hence, they are seldomly used these days for lubrication. They are still used as blending agents in petroleum-based lubricants to get improved oiliness.

- Mineral or Petroleum oils: These are basically lower molecular weight hydrocarbons with about 12 to 50 carbon atoms. As they are cheap, available in abundance and stable under service conditions, hence they are widely used. But the oiliness of mineral oils is lower than natural oils, so the addition of higher molecular weight compounds like oleic acid and stearic acid is used to increase the oiliness of mineral oils.

- Blended oils: No single oil possesses all the properties required for a good lubricant and hence addition of proper additives is essential for an optimum performance. As mentioned before, the addition of higher molecular weight compounds like oleic acid, stearic acid, palmetic acid or vegetable oil (e.g., coconut oil, castor oil) increases the oiliness of a mineral oil.

Characteristic of good lubricating oils:

(1) high boiling point, (2) low freezing point, (3) adequate viscosity for operational window, (4) high resistance to oxidation and heat, (5) non-corrosive properties and (6) stability to decomposition at the operating temperatures.

Fig-5 Liquid lubrication

Semi-solid Lubricants or Grease

A “grease” is a semi-solid lubricant obtained by combining a lubricating oil with a thickening agent. The lubricating oil is the principal component, and it can be either petroleum oil or a synthetic hydrocarbon of either low or high viscosity. The thickeners primarily consist of special soaps of Li, Na, Ca, Ba, Al, etc. Non-soap thickeners include carbon black, silica gel, polyureas and other synthetic polymers, clays, etc. Greases can support a much heavier load at low speeds than liquid lubricants. Compared to lubricating oils, greases cannot effectively dissipate heat from the bearings.

Fig-6 Semisolid/Grease Lubrication

Solid Lubricants

They are preferred where,

- The operating conditions are such that a lubricating film cannot be secured by the use of lubricating oils or greases.

- Contamination (by the entry of dust particles) of lubricating oils or grease is unacceptable.

- The operating temperature or load is too high even for a grease to remain in the contact.

- When combustible lubricants must be avoided.

Solid lubricants are used either in dry powder form or with binders to make them effectively stick to the metal surfaces while in use. They are available as dispersions in non-volatile carriers like soaps, fats, waxes, etc and as soft metal films. The most common solid lubricants are graphite, molybdenum disulphide, tungsten disulphide and zinc oxide. They can withstand temperatures up to 650° C and can be applied in continuously operating situations. Solid lubricants are also often used as additives to mineral oils and greases. Other solid lubricants in use are soapstone (talc) and mica.

Graphite: It is the most widely used of all solid lubricants and it can be used either in powder or suspension form. It is soapy to touch; non-inflammable and stable up to a temperature of 375° C. Graphite has a flat plate like structure and the layers of graphite sheets are arranged one above the other and held together by weak Vander Waal’s forces. These parallel layers which can easily slide one over the other make graphite an effective lubricant. Additionally, graphite layers have the tendency to absorb oil and to be wetted by it.

Molybdenum Disulphide: It has a sandwich- like structure with a layer of molybdenum atoms in between two layers of sulphur atoms. Poor inter-laminar attraction helps these layers to slide over one another easily. It is stable up to a temperature of 400° C.

Fig-7 MoS2 Solid lubricantion

Properties of Lubricants

- Viscosity

- Flash Point and Fire Point

- Cloud Point and Pour Point

- Aniline Point

- Corrosion Stability

Viscosity: The resistance to flow of liquid is known as viscosity. The unit of viscosity is poise. It is the most important single property of any lubricating oil because it is the main determinant of the operating characteristics of the lubricant. If the viscosity of the oil is too low, a liquid oil film between two moving/sliding surfaces cannot be maintained. On the other hand, if the viscosity of the oil is too high, excessive friction will result. Effect of temperature on viscosity: Viscosity of liquids decreases with increasing temperature and, consequently, the lubricating oil becomes thinner as the operating temperature increases. Hence, viscosity of good lubricating oil should not change much with change in temperature, so that it can be used continuously, under varying conditions of temperature. The rate at which the viscosity of lubricating oil changes with temperature is measured by an arbitrary scale, known as Viscosity Index (V. I). If the viscosity of lubricating oil falls rapidly as the temperature is raised, it has a low viscosity index. On the other hand, if the viscosity of lubricating oil is only slightly affected on raising the temperature, its viscosity index is high.

Flash Point and Fire Point: Flash point is the lowest temperature at which the lubricant oil gives off enough vapours that it would ignite for a moment, when a tiny flame is brought near it; while Fire point is the lowest temperature at which the vapours of the lubricant oil burn continuously for at least five seconds, when a tiny flame is brought near it. In most cases, the fire points are 5° C to 40° C higher than the flash points. The flash and fire points do not have anything to do with lubricating capacity of the oil, but these are important when oil is exposed to high temperature conditions. A good lubricant should have flash point at least above the temperature at which it is to be used. This safeguards against fire risk during the use of lubricant.

Cloud Point and Pour Point: When the lubricant oil is cooled slowly, the temperature at which it becomes cloudy or hazy in appearance, is called its cloud point; while the temperature at which the lubricant oil cease to flow or pour, is called its pour point. Cloud and pour points indicate the suitability of lubricant oil in cold conditions. Lubricant oil used in a machine working at low temperatures should possess low pour point; otherwise, solidification of lubricant oil will cause jamming of machine. It has been found that presence of waxes in the lubricant oil raise pour point.

Aniline Point: The aniline point of the lubricant oil is defined as the minimum equilibrium solution temperature for equal volumes of aniline and lubricant oil samples. It gives an indication of the possible deterioration of the lubricant oil in contact with rubber sealing, packing, etc. Aromatic hydrocarbons tend to dissolve natural rubber and certain types of synthetic rubbers. Consequently, low aromatic content in the lubricant oil is desirable. A higher aniline point means a higher percentage of paraffinic hydrocarbons and hence, a lower percentage of aromatic hydrocarbons. Aniline point is determined by mixing mechanically equal volumes of the lubricant oil samples and aniline in a test tube. The mixture is heated, till homogenous solution is obtained. Then, the tube is allowed to cool at a controlled rate. The temperature at which the two phases (the lubricant oil and aniline) separate out is recorded at the aniline point.

Corrosion Stability: Corrosion stability of the lubricant oil is estimated by carrying out a corrosion test. A polished copper strip is placed in the lubricant oil for a specified amount of time at a particular temperature. After the stipulated time, the strip is taken out and examined for corrosion effects. If the copper strip has tarnished, it shows that the lubricant oil contains chemically active substances which cause the corrosion of the copper strip. A good lubricating oil should not affect the copper strip. To retard corrosion effects of the lubricant oil, certain inhibitors are added to them. Commonly used corrosion inhibitors are organic compounds containing P, As, Cr, Bi or Pb.

Essential requirements for a good lubricant

- It should have a high viscosity index (VI).

- It should have flash and fire points higher than the operating temperature of the machine.

- It should have high oiliness.

- The cloud and pour points of a good lubricant should always be lower than the operating temperature of the machine.

- The volatility of the lubricating oil should be low.

- It should deposit the least amount of carbon during use.

- It should have higher aniline point.

- It should possess a higher resistance towards oxidation and corrosion.

- It should have good detergent quality.

References

- [1] TABOR, D. Modern Problems in Friction and Lubrication. Nature 182, 980–981 (1958). https://doi.org/10.1038/182980a0

- [2]DOWSON, D., LONGFIELD, M. An Elastohydrodynamic Lubrication Experiment. Nature 197, 586 (1963). https://doi.org/10.1038/197586a0

- [3]YOUNG, N. Capillary Lubrication. Nature 216, 1246 (1967). https://doi.org/10.1038/2161246a0

Be the first to comment