Founder of TriboNet, Editor, PhD (Tribology), Tribology Scientist at ASML, The Netherlands. Expertise in lubrication, friction, wear and contact mechanics with emphasis on modeling. Creator of Tribology Simulator.

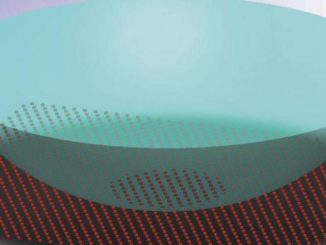

Antiwear tribofilm growth – AFM study

In a wide range of tribological components, the lubricant is not capable of separating the surfaces and areas of metal-to-metal contact occurs. However, the metal-to-metal contact area can be minimized by the action of additives, which are widely used in the lubricants. They proved to form protective tribofilms on the surfaces and reduce the friction and wear. Despite the significance of the process, the exact pathways of the film generation are not well understood. Particularly, there is no consensus on the mechanisms of self-limiting film growth, which would help to develop predictive models.

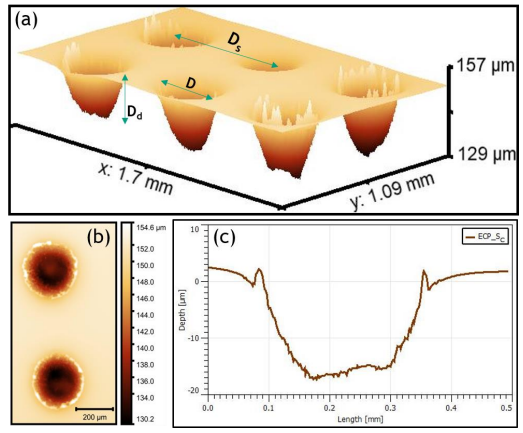

A joint team of researchers from University of Pennsylvania and Exxon Mobil Research and Engineering explored the generation of the tribofilm due to a widely used ZDDP additive using Atomic Force Microscpope. The AFM tip was used as a pin to slide against Fe-coated (and also uncoated) Si substrate in presence of ZDDP containing stock under a range of temperatures and applied normal loads. It was found, that the tribofilm growth rate as a function of both load and temperature indicated a clear exponential dependence. Specifically, at lower contact stresses or temperatures, the growth rate of the film is slower. Based on these results, it was concluded that the tribofilm growth occurs through a stress and thermally activated tribochemical reactions. Both, the thermal and load dependence curves were well fitted using Arrhenius model. Moreover, it was found that the growth morphology remains the same for both, Fe coated and uncoated Si substrates.

The findings can explain the self-limiting behavior of the thickness of the tribofilms. Specifically, since the tribofilm has a lower elastic modulus than the tip or substrate, the increase of the film thickness leads to lower contact pressure. Since the growth of the tribofilm is slower at lower stresses due to lowered amount of the stress-induced reactions, the growth of the film is balanced by the wear. Therefore, a self-limiting growth process is established.

The results presented in the work can be used to design new additives, as well as to incorporate the growth and rupture of tribofilm layers into material wear models.

The details of the model can be found in the original article by N. N. Gosvami, J. A. Bares, F. Mangolini, A. R. Konicek, D. G. Yablon, R. W. Carpick, Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts.