I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

How do texturing and coating affect surface Tribology?

Table of Contents

Introduction

Researchers worldwide have focused on reducing friction and enhancing the tribological properties of materials to save energy and resources. Surface texturing, a key surface engineering technique, plays a crucial role in improving surface tribological properties, particularly in lubricated contact conditions. By creating micro-dimple patterns on material surfaces, surface texturing generates hydrodynamic pressure within these dimples, facilitating the formation of thick lubricant films at solid-solid interfaces and consequently reducing friction. Various texturing methods, including laser surface texturing, micro-electro discharge machining (EDM), abrasive water jet machining, and ion beam machining, have been employed for this purpose, but they often have limitations such as surface damage and the formation of debris or burrs. Electrochemical polishing (ECP) emerges as a promising technique, as it dissolves debris and burrs electrochemically, leaving a smooth textured surface. Surface coatings play a pivotal role in enhancing the tribological performance of materials, impacting factors like the coefficient of friction (COF) and wear rate. These coatings offer solutions for tribological contacts by facilitating easy shear mechanisms, reducing the need for liquid lubrication. Various types of solid lubricant coatings, including diamond-like carbon (DLCs) and tungsten carbide with carbon (WC/C) coatings, have been explored. Among these coatings, transition metal dichalcogenide (TMD) coatings have emerged as particularly significant contributors to improved surface frictional properties.

Figure-1 Surface texturing through EDM on steel surface [2]

Summary of Article-1

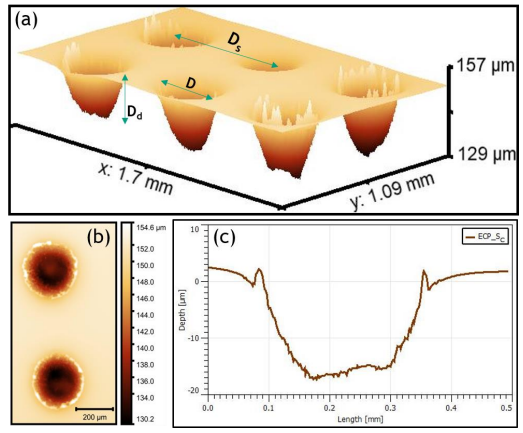

This study focuses on enhancing the tribological properties of surfaces that experience continuous lubricated sliding motions, such as those found in automobile engine piston cylinders, mechanical components like rings and tappets. The aim is to improve surface properties to increase component lifespan and conserve energy and resources. To achieve this, the research combines surface texturing using electrochemical processing (ECP) with the application of transition metal dichalcogenides (TMD), specifically a molybdenum-selenium-carbon (MoSeC) film, onto steel surfaces. The study involves block-on-ring experiments conducted under lubricated conditions to assess the coefficient of friction (COF) across various lubrication regimes. Results indicate that MoSeC-coated circular patterns on the steel surface significantly improve frictional properties compared to smooth surfaces in all lubrication conditions [1].

Figure-2 Texture profiles from ECP method [1]

Summary of Article-2

This study explores the impact of a hybrid surface modification process, combining surface texturing and coating, on the tribological properties of steel surfaces under lubricated conditions. The steel surface was textured using micro-electric discharge machining (micro-EDM) to create specific patterns (rectangular and circular), followed by the application of a tungsten-sulphur-carbon (WSC) coating through magnetron sputtering. Tribological testing was conducted using a block-on-ring setup, and the results were compared with those from a smooth uncoated specimen. The findings indicated significant improvements in tribological properties, especially in specimens with circular dimple patterns. The WSC-coated circular dimple specimens exhibited a reduction in the coefficient of friction (COF) by 7-12% in the boundary lubrication regime and 9-25% in the mixed and hydrodynamic lubrication regimes compared to the untreated specimen [2].

Reference

Be the first to comment