I am a postgraduate researcher at the University of Leeds. I have completed my master's degree in the Erasmus Tribos program at the University of Leeds, University of Ljubljana, and University of Coimbra and my bachelor's degree in Mechanical Engineering from VTU in NMIT, India. I am an editor and social networking manager at TriboNet. I have a YouTube channel called Tribo Geek where I upload videos on travel, research life, and topics for master's and PhD students.

Tribology test design for Oral medicines

Table of Contents

Introduction

Tribology test methods have been widely applied to semi-solid foods and particulate systems, but detailed interpretation is still lacking. Friction results are typically analyzed using classical lubrication mechanisms like the Stribeck curve, which differentiates boundary, mixed, and full-film lubrication. While correlations between low friction and “creaminess” exist, more detailed insights are needed. Most tests average friction measurements over extended periods, much longer than typical mastication times, making it difficult to track food degradation and structural changes. Oral sensory perception, described as a journey, involves continuous analysis of texture attributes during mastication, with friction playing a crucial role. Ideally, a bench-test would mimic specific oral events like the first bite, mastication, propulsion, or swallowing, under physiologically relevant conditions. The test should provide high-resolution friction data and allow in-situ observation of in-contact films, using repeatable materials and requiring only a small sample to enable gradual degradation or processing during the test.

When designing a tribology test to mimic oral processing, several critical factors need careful consideration. Firstly, understanding the effects of lubricant supply and inlet dynamics is crucial. This involves determining how lubricants interact and influence the formation of protective films on surfaces, mimicking the conditions found in the oral cavity. Secondly, replicating the dynamics of tongue sliding is essential. Factors such as the speed, motion patterns, contact size, and pressure exerted during oral movements play a significant role in determining the frictional behavior of food or medicine during mastication and swallowing. Thirdly, the time-scale of friction measurements is pivotal. It is important to conduct measurements at frequencies and durations that align with the rapid changes in forces and motions experienced during chewing and swallowing processes. Lastly, selecting appropriate test specimen properties is vital for accurate simulation. This includes choosing materials that mimic the mechanical properties of food or medicine, replicating surface textures that interact realistically with oral tissues, and incorporating saliva mimics to simulate the lubricating and enzymatic properties present in the mouth. By addressing these factors comprehensively, tribology tests can effectively simulate and evaluate the frictional behavior and performance of materials during oral processing, leading to improved understanding and design of oral products and formulations.

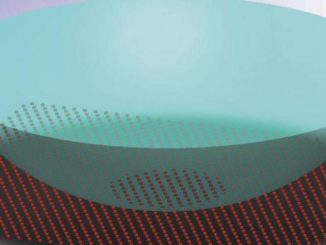

Figure-1 The evolution of film thickness for fluid-like foods or beverages as they traverse oral surfaces during consumption transitions from being primarily influenced by rheological factors to being dominated by tribological properties [2].

Lubricant supply and inlet effects on film formation

In classical lubrication studies, the assumption of fully-flooded conditions with a continuously replenished fluid inlet is standard practice for generating and controlling lubricant films. This approach, typically depicted with a converging inlet, ensures optimal lubrication dynamics. However, in oral contexts, such as during the consumption of semi-solid foods like yogurt, this model diverges significantly. In the mouth, food undergoes shearing at the tongue-palate interface before being swallowed. Unlike in classical lubrication scenarios, where lubricant films are continuously replaced, the food film in the mouth persists within the tongue-palate contact area. Here, it undergoes mechanical and chemical transformations, influenced by saliva interactions. The size of the food film in the mouth is relatively large (~cm), contrasting with the movement range of the tongue, which slides and presses against the palate. This situation resembles a non-replenished lubricated contact, challenging traditional lubrication assumptions. In conclusion, we propose employing a test method that minimizes the role of continuous replenishment, as suggested by a non-replenished protocol. This approach involves a reciprocating sliding motion where the stroke length equals or is less than the contact diameter. By adopting these conditions, there is minimal replenishment of fluid at the contact center, and the lubricating film depends on the initial material charge captured under load. It is crucial to measure friction at a high temporal resolution to accurately track the degradation of the food over time. This approach ensures that the tested fluid sample remains representative throughout the test, allowing changes in film properties such as rheology, structure, or phase to be monitored continuously.

Tongue Palate motion and load conditions

In classical lubrication, key factors influencing lubrication response include sliding speed, kinematics, and contact pressure. During oral processes, the tongue moves in a reciprocating motion against the palate, where the contact length exceeds the sliding distance. Typical sliding speeds range from 10 to 100 mm/s. Traditionally, tests focus on low-speed (<10 mm/s) scenarios to minimize hydrodynamic film formation, assuming inlet-dominated lubrication mechanisms. However, oral film formation involves shearing a captured sample, influenced by the initial viscosity of the food, shear-induced degradation, selective loss of soluble components, and surface deposition. Unlike static tests at discrete speeds, tongue motion during mastication varies dynamically, contributing to a complex friction response.

Timescale of friction measurement

Another crucial parameter is the time scale of friction data sampling. In most tribology tests, friction is typically measured under steady-state lubrication conditions, where measurements are averaged over extended periods. This approach makes it challenging to capture friction changes related to mechanical degradation of food samples or to reflect rubbing times typical of oral film duration. For instance, during swallowing, the peak pressure duration is reported to be less than <1 second. Moreover, when evaluating texture and mouthfeel attributes, such as the effects of solid suspensions in fluids, transient friction properties likely contribute significantly to oral perception and palatability. This aspect is particularly relevant in medicines intended for young and elderly patients.

Testing specimen properties

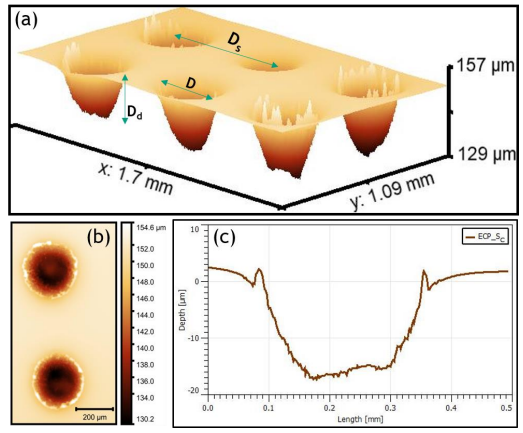

The palate is typically represented by a harder, smoother material such as glass or steel; in this study, a PCX glass lens was used. However, developing more realistic tissue mimics with optimized mechanical, textural, and surface chemistry properties is an important objective in advancing oral tribology tests. Although this study utilized a silicone specimen with a rough surface to simulate the tongue model, it does not address the development of these tissue mimics. Saliva plays a crucial role in the initial stages of food digestion by breaking down carbohydrates with its enzymes, influencing the oral processing. Therefore, it should be integrated into tribology experiments. Methods include using tongue or palate mimics coated with absorbed saliva constituents or incorporating (artificial) saliva into fluid food samples. In this study, a simple mucin solution was adsorbed onto the test surfaces.

Reference

[3] https://pcs-instruments.com/wp-content/uploads/2021/04/Introduction-to-Food-Tribology.pdf