I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Journal bearing

Table of Contents

Introduction

The application of using rotary machines to convert the rotating energy from different sources to useful energy is well known. For these rotating machines, there is always one rotating part that is separated from the stationary portion of the machine. This is fulfilled by using the bearings [1]. The bearings help in allowing the surfaces of the rotating part to slide relative to the stationary part. Journal bearings are the most commonly used bearings in most mechanical applications.

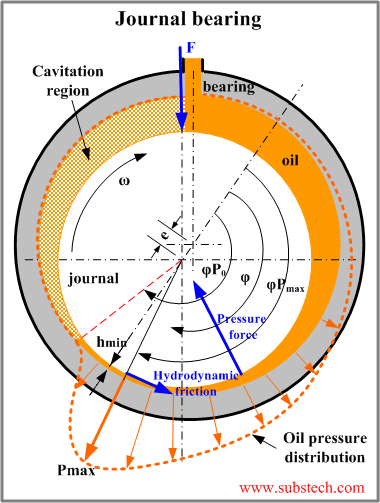

Fig-1 Schematic representation of journal bearings [2]

Definition

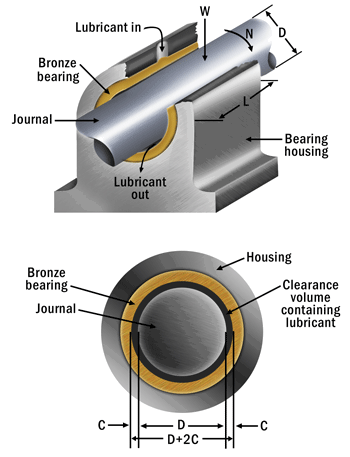

Journal bearings are the simplest types of bearings that allows the shaft to rotate freely within a supporting sleeve. The part of the shaft which is fit in these bearings is called a journal hence the name journal bearing. These bearings do not have rollers to support the radial loads however they are capable of supporting these weights which is due to the weight of shafts.

Fig-2 Schematic representation of journal bearings with components [3]

Working principle

Journal bearings operate in both boundary and hydrodynamic lubrication regimes, it operates at the boundary lubrication regime at the start and shutdown of the bearings. At the start and shut down of the bearing operation there is metal-to-metal contact leading to boundary contacts. After the start, the oil is supplied at the junction that causes the pressure and hydrostatic lift thus it operates at the hydrodynamic lubrication regime. The hydrodynamic fluid film helps in higher load support and also operates at high rotational speeds.

Fig-3 Schematic representation of journal bearings working principle [4]

Types of journal bearings

There are mainly two types based on their assembly or setup. They are integral or plain bearings and two-piece bearings.

Plain or integral bearings

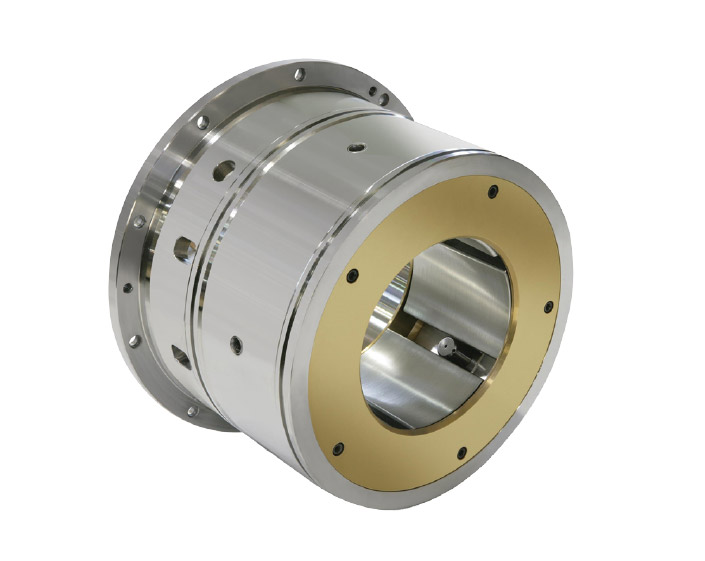

In this type of bearing it is assembled into the object as a hole that acts as a bearing surface. The most commonly used is the pillow block bearing, in this bearing the materials used inside and on the bearing surfaces are different. The housing of these bearings is made of cast iron and the surface of the bearing is made of chromium steel alloys. The lubrication in these bearings is supported by the grease nipples which supply the lubrication thereby maintaining the good lubrication property.

Fig-4 Schematic representation of plain journal bearing [5]

Two-piece bearings

In this type of bearing they have two parts lower and upper parts; where the lower part of the bearing is positioned on the application and the upper part is removable. These parts upper and lower are also referred to as shells which are used on large diameters as in the case of a crankshaft. These bearings are usually manufactured larger than their housing and are compressed to fit the application during installation.

Fig-5 Schematic representation of a two-piece journal bearing [6]

Lubrication in journal bearings

The lubrication in bearings is important to protect their surfaces from corrosion and seal them against contamination. The lubrication also helps in creating the barrier between the rolling contact and sliding surface and helps in providing heat transfer. Thus bearing lubrication should be understood for its better functionality in various applications.

Oil lubrication:

The requirement of oil lubrication in journal bearing is used for cooling and clearing debris and contaminants. In case of the high-speed applications, oil lubrication is preferred over grease. The oil viscosity used in different bearing applications depends on the rotating speeds, operating temperature, and applied load.

Grease lubrication:

Grease lubrication is used in the journal bearing when cooling of the bearing is not considered and in case of low-speed conditions. This lubrication is mostly suited when there is a frequent start-stop in the bearing operation to prevent shock loading. In case of high temperatures, low speed, and higher loading applications then the greases with higher viscosity base oil can be used. Whereas in case of low-temperature applications then the grease with lower viscosity base oil can be used.

Reference

[2] https://www.substech.com/dokuwiki/doku.php?id=hydrodynamic_journal_bearing

[3] https://www.machinerylubrication.com/Read/29654/journal-bearing-oil

[4] https://savree.com/en/encyclopedia/plain-bearing

[5] https://www.waukbearing.com/en/products/fluid-film-bearings/journal-bearings.html

Leave a Reply

You must be logged in to post a comment.

awesome blog and referal link and some are here for study purpose https://mcqquestions.net/practice/mcq-on-bearing

Here you have an online Journal Bearing App to test the theory and predict the hydrodynamic pressure built-up 😉

http://www.i-tribomat.eu –> TRIBOLOGY UNIVERSE

(you need to register but it free!)