I'm an Erasmus Mundus Scholarship recipient in the field of Tribology of Surfaces and Interfaces. The masters program takes place in four different universities namely University of Leeds (UK), University of Ljubljana (Slovenia), University of Coimbra (Portugal) and Lulea Technical University (Sweden).

Oil Sampling Ports

Table of Contents

Introduction:

A powerful method for inspection of oil wetted machine parts is wear particle analysis. Wear Particle analysis (WPA) is very important to identify the wear mechanisms [1].Complex machines and their parts (which are huge) in an industry can’t be examined physically under microscope or using weight loss techniques to identify the wear rate and the mechanism of wear. For, this in-order to identify the wear mechanisms and to assess the condition of life of an asset, predict its future usability and life evaluation we need alternative ways of identifying the wear rate, wear volume and wear mechanisms leading to the failure. So, we can use oil sampling techniques wherein we draw out lubricating oil from the system to see for wear particles their shape, size, concentration etc., and to identify the wear phenomena and mechanisms behind it. The collected oil has wear particles which clearly help us in understanding the phenomena behind the wear mechanism as they are originating from the components and they carry these detailed information along with them. This is the process which is usually performed in industries and they do it following certain standard procedures with certain time intervals between each test or based on the number of operating hours of the machine.

Oil sampling ports for WPA:

a. Oil collection:

The lubricant particles contain comprehensive and significant information about the machine’s state. Shape, size, composition, and concentration of wear particles are used to infer this information. The wear mechanisms within the machine may be identified with the particle properties, which are sufficiently precise to enable prediction of the machine’s future behaviour. We now know the significance of WPA but one important thing is from where we collect the oil sample in-order to perform the WPA. This is extremely vital and the position from where we sample our oil can determine a lot of things. Collecting oil from the wrong place can lead to false results and finally lead to machine failures [2].

b. Sampling ports (Primary and Secondary):

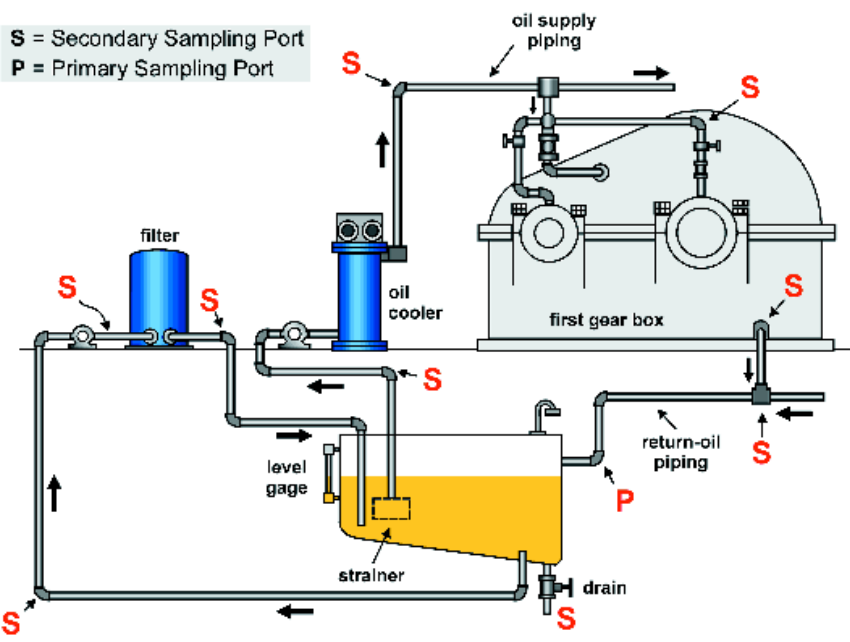

For this reason, we have several locations and ports from where the oil can be sampled. These are namely primary and secondary oil sampling ports. The primary sampling port should ideally be very close to the oil reservoir and on the return line immediately before the reservoir. The reason for this is due to the fact that at this point the lubricating oil has circulated and lubricated all the components in the system where it was designed to lubricate. This indicates us the wear particle concentration in the system. We can quickly determine if an individual part/component is to blame for the wear particle concentration by collecting samples from secondary sampling ports that are placed before and after the component. The secondary sampling port assists in the simple identification of the location of the problem’s root cause if the primary sampling port exhibits extremely high concentration of wear particles.

Fig-1 A system depicting Primary and Secondary ports

c. Components involved:

The system described above includes an oil reservoir which is used for storing and recirculating the oil to lubricate the parts, as well as a filter, an oil cooler, oil supply piping, a gear box, return oil piping, and primary, secondary sampling ports. It describes a system for circulating lubricating oil in which the lubricant is provided to the gears to ensure their smooth and continuous operation [3].

d. Working principle:

Under normal operating conditions the oil should initially be collected from the primary sampling port i.e. after passing and lubricating all the components and right before it gets into reservoir. The placement of these ports within a system is essential to monitor and enhance the system condition. As mentioned earlier we get to identify all the secondary ports and primary port and later we perform WPA to find out the health of the system. Once we analyse the sample from primary port and if it has it’s WPC within the defined limits we don’t do any further investigation and proceed with the normal operations of the system, whereas if we find high levels of WPC from the primary sampling port then it there is an imminent need to perform further analysis and this high WPC can be from any of the component or components in a system which can be found out using analysis through secondary ports. As mentioned earlier secondary ports are placed right after and before the component to see if it’s contributing to high WPC. So, in this case we take oil samples from all the secondary ports and try to see which component is responsible for high WPC. Once we identify that component/part we just repair/replace it and continue with the operations. There’s secondary port even on the reservoir named as drain in fig-1 which is important in identifying the sedimentation or settling down of the particles in oil.

In-line, On-line and Off-line techniques:

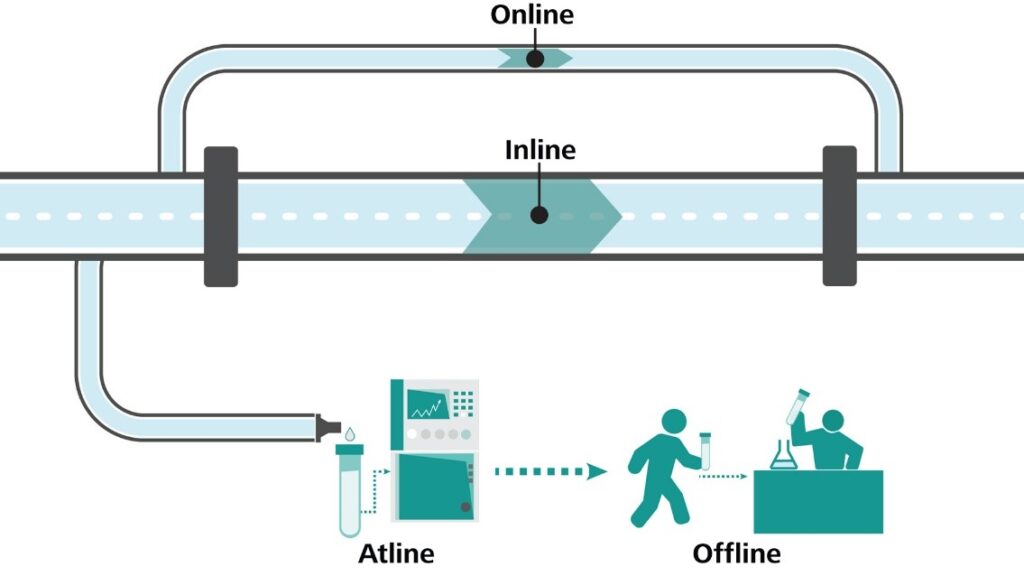

The oil can be collected in different ways such as inline, online and offline techniques.

a. In-line technique:

In this the sensor is directly placed for WPA in the flow which is the most expensive of all.

b. On-line technique:

On-line technique creates a bypass from the original flow channel where the fluid comes and the sensors are placed there for WPA

c. Off-line technique:

In off-line analysis usually the oil is taken out in a container using standard procedures which is then sent to laboratory for WPA. It’s not the best due to possibility of contamination of oil but is the cheapest of all techniques.

It takes lot of time to get the results in off-line case whereas in other methods we get the results instantly from the software which analyse (using image detection and AI) its shape, size etc and try to correlate it with existing data in-order to find out the wear mechanism. This entire process is depicted in the below figure.

Fig-2 In-line, On-line and Off-line techniques [4]

References:

- Laghari, Mohammad &Memon, Qurban&Khuwaja, Gulzar. (2004). Knowledge based Wear Particle Analysis. International Journal of Information Technology.

- “Oil sampling.” Machinery Lubrication,https://www.machinerylubrication.com/Read/128/world-class-oil-sampling

- “Fluid sampling.” Society of Tribologists and Lubrication Engineers (STLE), March 2022, https://www.stle.org/files/TLTArchives/2022/03_March/Lubrication_Fundamentals. aspx

- “On-line, In-line and Off-line analysis.” Metrohm, Feb 3, 2020, https://metrohm.blog/2020/02/03/we-are-pioneers-metrohm-process-analytics/comment-page-1/

Be the first to comment