Automotive researcher, currently researching Tribological applications with graphene. More than 30 years experience on tech center at MAHLE. Fields of expertise include ring free shape process, bore deformation and surface finish, and engine friction. Author of more than 30 international technical papers. Specialties: Tribology, piston ring, surface finish, modelling, graphene applications.

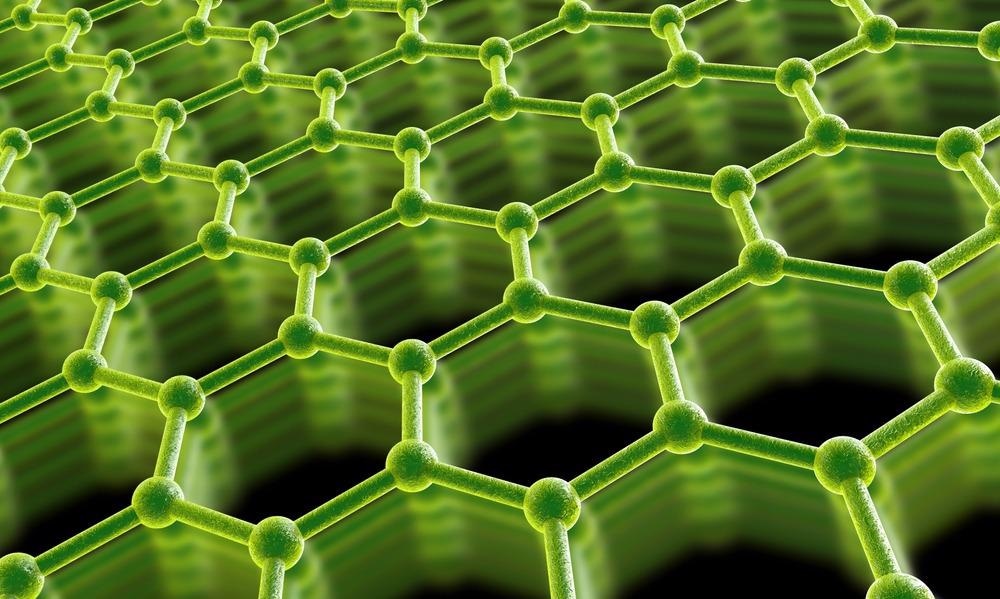

Graphene-Based Materials for Tribological Engineering Applications

Graphene has been applied on several products, from electronic devices to additives for concrete and polymers due to its unique mechanical, electrical and thermal properties . A growing interest is the use of graphene-based materials in mechanical applications to reduce wear and friction.

A recent MDPI review paper, Tomanik, E.; Christinelli, W.; Souza, R.M.; Oliveira, V.L.; Ferreira, F.; Zhmud, B. Review of Graphene-Based Materials for Tribological Engineering Applications. Eng 2023, 4, 2764-2811., gives more attention to engineering applications such additives for lubricants for gearboxes, internal combustion engines and refrigerator hermetic compressors. For compressors the reviewed papers report savings on energy consumption from 4 to 20%. Domestic refrigerators are a significant share of electrical consumption and hence CO2 emissions.

In addition to graphene’s few layers, the paper also gives focus to less expensive Graphene Nanoplatelets (GNP). As most of the covered GNP additives do not contain metals neither Sulphur, GNP is an attractive alternative to current Friction modifier and anti-wear lubricant additives.

The paper has also dedicated chapters for:

- Graphene-Based Materials

- Functionalization of Graphene-Based Materials for Tribological Applications

- Graphene Functionalization for Use in Lubricants

- Tribological Mechanisms of Graphene-Based Materials

- Additive for oil

- Additive for grease

- Use as dry lubricant.

- Use as coatings.

- Graphene as Combustion Improver

- Graphene Derivatives and Chemical Aspects

- In-Situ Graphene Formation, “Superlubricity”

Any amount of graphene-based material for industrial applications will contain particles with variation in terms of size, number of layers etc. Even if the sample contains mostly graphene particles with 1 to 6 layers, the relative share of such small particles in area and volume will be much lower than the number of particles. Figure below shows the relative share of number of particles, area and volume for two samples having mostly particles with few layers. Despite containing mostly particles of few layers, the volume share on both samples is dominated by particles of 6 or more layers.

Potential mechanisms that lead to friction reduction were also discussed. See figure below.

Graphene’s potential tribological mechanisms. (a) Typical FM tribofilm (b) Surface filling and mending (c) Polishing effect (d) nano roller bearings (e) Hydrodynamics at (1) low shear rate, (2) high shear rate. (f) Thermal effects (g) Superlubricity, incommensurable contact.

Also briefly discussed is the impact of GNP on fluid rheology.

Proposed mechanism for graphene (a) increasing viscosity at lower shear rates and (b) decreasing it at higher ones.

Paper can be download here.

Leave a Reply

You must be logged in to post a comment.

Nice aproach. Very interesting!

Great paper highlighting the many attributes that graphene can and will influence within the tribological framework going forward.