I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Bio-tribological Advancements in Modular Interface of a Joint Implant

Introduction

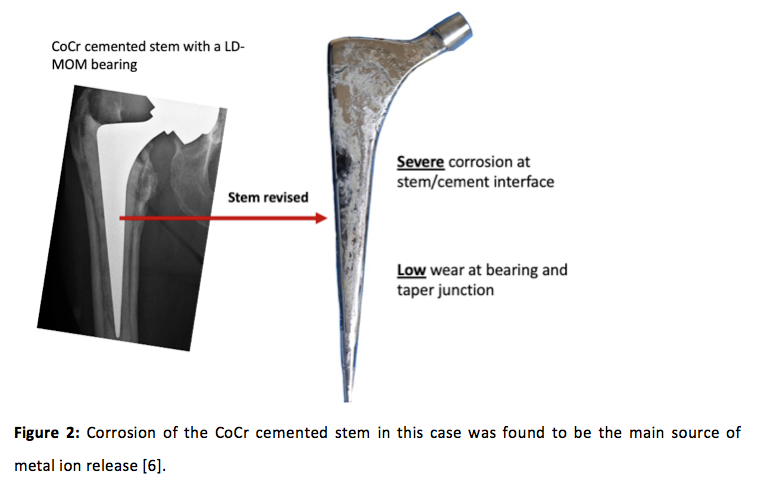

In daily activities, articulating interfaces undergo three-dimensional dynamic motion and loading, transmitting frictional forces to modular interfaces, causing fretting wear and corrosion. This phenomenon is observed in various artificial joints, including hips, knees, shoulders, and spinal fixation assemblies. Fretting corrosion is a common occurrence in these systems.

Important factors

Several factors are linked to increased corrosion and/or fretting scores at the taper interface, including femoral head size, surface roughness, femoral head-femoral stem offset, and material combinations. Material combinations play a crucial role in fretting corrosion, with CoCrMo or stainless steel paired with titanium alloy exhibiting more severe fretting corrosion compared to others. The use of a ceramic ball head with a titanium alloy femoral stem tends to result in relatively light fretting corrosion. Furthermore, compared to CoCrMo, a femoral stem made of low elastic modulus titanium alloy and a ceramic ball joint increases fretting corrosion. Conversely, the use of a PEEK femoral stem reduces fretting corrosion.

Fig-1 The fretting corrosion at the modular interface of the joint implant [2]

Design and manufacturing parameters of modular interfaces significantly influence fretting motion. Larger diameters in metal-on-metal bearing surfaces lead to more severe fretting corrosion. Taper shape, including cone angles and lengths, affects fretting corrosion in metal-on-metal joints. Surface morphologies and textures can enhance interface fixation, with increased cone roughness resulting in more serious fretting corrosion. The bearing surface between the femoral head and acetabular cup also plays a role, and under adverse conditions, large-diameter metal-on-metal bearing surfaces can produce high friction coefficients, causing severe fretting corrosion. Patient weight directly impacts fretting corrosion damage, with females at a higher risk for joint reduction due to smaller implant sizes.

References

[1] https://www.opnews.com/2021/12/corrosion-of-orthopaedic-implants/17241

Be the first to comment