I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Circular economy in tribology

Introduction

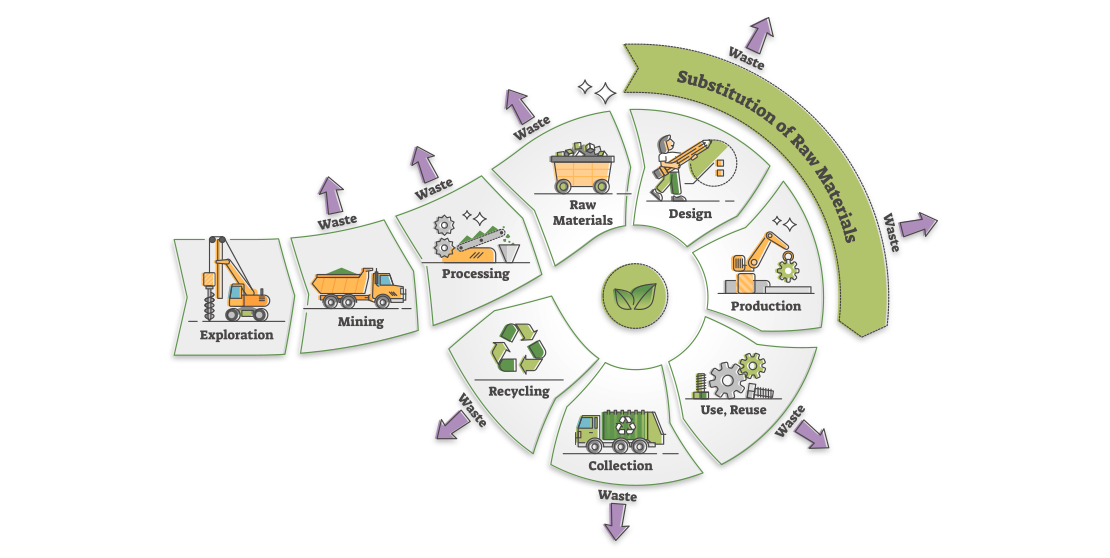

Product manufacturing involves generating wastes from the process involved in those manufacturing techniques. Reducing these wastes from product manufacturing is a challenge of the 21st century. In this context circular economy comes into the picture which is a collection of technical, management, economic and sustainable strategies in manufacturing. Thus, practicing the principles of circular economy involves reducing waste thereby improving the sustainability in the chain of manufacturing. These principles involve reusing, sharing, repairing, remanufacturing, and recycling products and materials. The main goal is to extend the life cycle and reduce the overall waste in manufacturing.

Fig-1 Circular economy in manufacturing [1]

The consideration in circular economy begins in the initial stage of the manufacturing process i.e. design stage which involves creating a component that can be reused and recycled as much as it is possible. Designing a component with a good assembly can help in replacing the damaged part and assembling the new one to continue the process, rather than changing the entire component. The cyclic model or steps in circular economy involves making, use, return, replace, reuse and make. This eliminates the waste from the traditional linear economy which flows as take, make, use and dispose of. In a circular economy, the materials are not discarded and considered waste rather it is brought back into the economy through various means.

Fig-2 Steps in circular economy [2]

The challenges in manufacturing sectors involved rethinking the primitive methods of designing, producing, and shipping the products and making this process more regenerative. There is more awareness about this wastage and consumers demand the products to be more sustainable which involves less waste. Thus, industries and manufacturers are finding various ways to increase sustainability by using recovered materials for their products, decreasing the wastage of materials in packing, and considering ways to reduce energy in the manufacturing stage. These steps are various ways to increase sustainability and thereby reduce the environmental impact.

Fig-3 Flow of circular economy and its loop [3]

New methods and standards have been developed to increase sustainable practices in manufacturing. This allows in creating the manufacturing systems that can be optimized to reduce the intake of energy. Further environmental impacting factors such as carbon footprints etc are taken care of while manufacturing reducing those impacts. Flexible designs are encouraged to improve the products and their adjustability to change. Thus, implementing all the steps could lead to improving sustainability and creating a suitable environment-friendly product.

Circular economy in tribology

Circular economy principles can be implemented in all manufacturing fields, tribological aspects can be influenced by these principles thereby reducing the environmental impacts. There are various studies conducted on tribological aspects considering the circular economy account. In a study conducted on hybrid composites, the importance of the tribological aspects of the natural fibers in a polymer composite is investigated. These studies help in improving sustainable materials in manufacturing [4]. In a work by Raj shah et.al., they have presented a comprehensive perspective on how tribology and sustainability are related and are linked to CO2 emission [5]. Further polymer tribology is another important area where the circular economy principles are well researched, Alejandra Ventura et.al., have investigated the mechanical and tribological aspects of ultra-high molecular weight polyethylene composites reinforced with virgin and recycled carbon fibers under lubricated conditions [6]. All these studies in tribology have considered the circular ecosystem as an important and sustainable practice for creating more environment-friendly products.

Reference

[1] https://www.rowse.co.uk/blog/post/manufacturing-a-circular-economy

Be the first to comment