I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Adhesive Wear

Table of Contents

Definition:

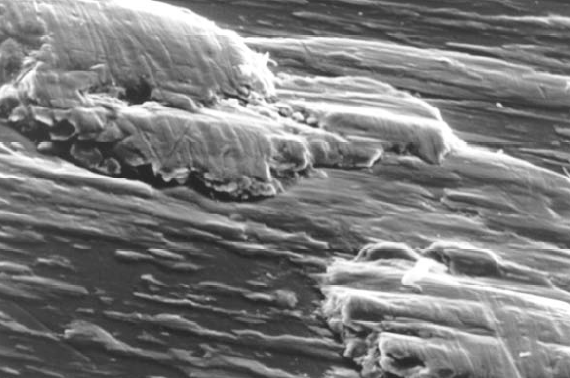

Adhesive wear is a type of wear that is caused on the surface of two materials that are in sliding contacts due to the large atomic bonding forces at the surface in comparison to the surrounding area of the material. The strong atomic bonding at the surface initiates the removal of the material from one of the surfaces due to the higher strength in the bonding. This is the most common type of the wear which is characterized by high wear rates and friction on the surface. The failure in the lubrication on the surface causes the contact in the sliding surface interface resulting in high adhesion and leading to adhesive wear [1]. The representation of the adhesive wear is shown in the Fig-1.

Fig-1 Adhesive wear of brass film on alumina [1]

Laws of adhesive wear:

According to Archard, in adhesive wear the wear volume of the materials is directly proportional to the normal force applied, sliding distance of travel and is inversely proportional to the hardness of the softer materials [2].

The laws can be written as:

- The wear volume is directly proportional to the sliding distance of travel (L).

- The wear volume is directly proportional to the applied load (W).

- The wear volume is inversely proportional to the hardness (H) of the material.

By combining all the laws, the wear volume (V) is given by

V = KWL/3H

Where, K depends on the type of contact (elastic/plastic), effect of the environment and mode of lubrication.

W is the applied load.

L is the sliding distance.

H is the hardness of the material.

Mechanism of adhesion:

Metal-metal adhesion:

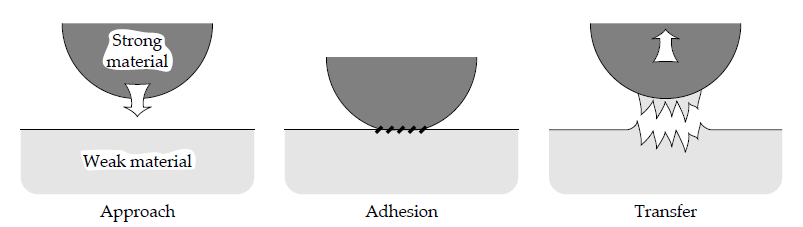

The adhesion in case of the metal-metal interaction is independent of the mutual solubility of the metals and the relative atomic size. [3] When the stronger material encounters the weaker metal then the transfer of the material takes place by the weaker to stronger by adhesion as shown in the Fig – 2. However, the electrons on the surface of the metal are not bound strongly to the structure resulting in bonding with the other metal surface that leads to adhesion [4]. Metals with different crystal structures behaves differently with the adhesion, hexagonal closed packed structure shows lesser adhesion compared to the other crystal structures. Also, materials with larger elastic moduli, higher hardness and surface energy suppress the adhesion [5].

Fig-2 Process of metal transfer due to adhesion [1].

Metal-polymer adhesion:

There is strong adhesion between the metals and polymers the strength of the adhesion in these contacts depends on the presence of the reactive non-metals in the polymers [6]. The strong interaction of the material between the metal and polymer takes place due to the chemical interactions and the weaker interaction takes place by the Van der Waals force of attraction [7].

Metal-ceramic adhesion:

The metal ceramic interaction are basically due to the chemical affinity and it is also found that the metals which do not form the stable oxides exhibits the lower friction coefficients. However, in case of the metal which forms stable oxides exhibits higher friction coefficients on the ceramic materials [8].

Adhesive wear in different asperity contacts:

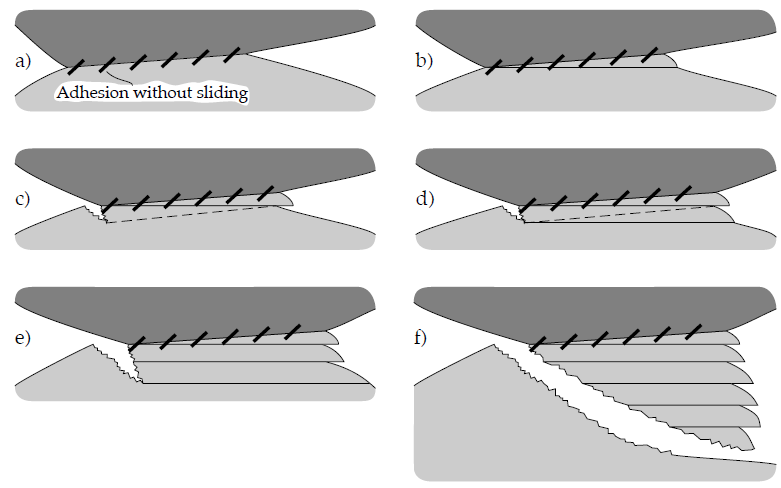

Flat asperity contact:

Severe plastic deformation occurs at these junction due to the combined action of adhesion and the sliding motion. When a constant vertical load is applied and a horizontal force is pulling either of the surfaces then there will be deformation in the series of shear bands causing the crack on the surface [9]. This mechanism is shown in the Fig – 3.

Fig-3 Schematic diagram of the formation of an adhesive transfer particle [1]

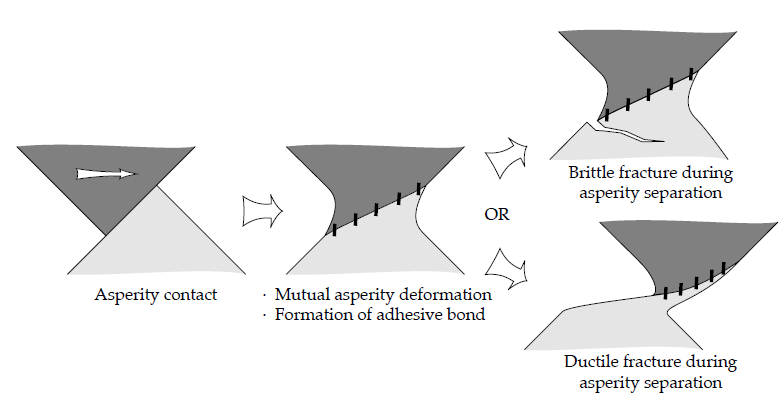

Sharp asperity contacts:

In this type of the contacts the material properties plays an important role in the asperity deformation. In case of the brittle materials the asperities break down producing the fewer wear particles. However, in ductile materials the asperities separate from the region and remains on the surface [10]. This mechanism is shown in the Fig – 4.

Fig-4 Alternative model of deformation in adhesive asperity contact [1]

Transfer layer formation:

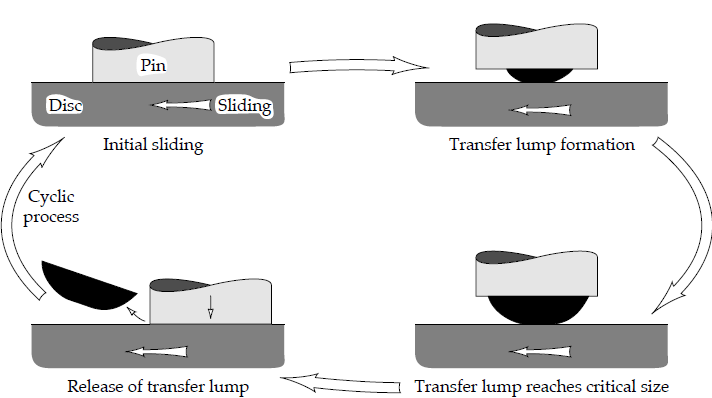

Transfer layer formation is the characteristic feature of the adhesive wear. The transfer layer which is formed due to the adhesion of the interacting surfaces is released to form the wear particles. When the interaction of the two metals takes place, there is a formation of mechanical alloying producing the transfer particle that consists of the lamellar of the two metallic surfaces [11]. The transfer layer formation mechanism can be explained using the Fig – 5. The sliding movement of the pin and disc forms the initial lump which is the transfer lamellar of the pin and disc surfaces. On further sliding motion, the lamellar reaches the critical size and withdraws from the interface forming the wear particles.

Fig- 5 Formation and removal of a transfer particle [1].

Research involving adhesive wear:

GA. Fontalvo et.al., studied the micro structural aspects of the adhesive wear in the tool steel (AISI M4), they found that the two main parameters influencing the wear behaviour was the carbide content in the materials and the distance between the carbides [12]. The adhesive wear of the fractal surfaces under normal contact was investigated for its adhesive wear mechanism. This investigation explained the effects of the surface material properties and interfacial adhesion on the adhesive wear of the rough surfaces in the fractal contacts [13]. K.P. Lijesh et.al., modelled the adhesive wear by considering the varying load sequence, in the past the Archard’s equations present the wear model based on the constant load theory however in this work, an attempt was made to study the wear volume based on the constant degradation of the friction coefficient under variable loading conditions [14].

References:

[1] Stachowiak, G.W. and Batchelor, A.W., 2013. Engineering tribology. Butterworth-heinemann.

[2] Popov, V.L., 2019. Generalized archard law of wear based on Rabinowicz criterion of wear particle formation.

[3] F.P. Bowden and G.W. Rowe, The Adhesion of Clean Metals, Proc. Roy. Soc., London, Series A, Vol. 233, 1956, pp. 429-442.

[4] D.H. Buckley, Surface Effects in Adhesion, Friction, Wear and Lubrication, Elsevier, 1981.

[5] M.E. Sikorski, Correlation of the Coefficient of Adhesion With Various Physical and Mechanical Properties of Metals, Transactions ASME, Series D – Journal of Basic Engineering, Vol. 85, 1963, pp. 279-285.

[6] W.C. Wake, Adhesion and the Formulation of Adhesives, Applied Science Publishers, London, 1982, 2nd edition.

[7] B.J. Briscoe and D. Tabor, Surface Forces in Friction and Adhesion, Faraday Special Discussions, Solid-Solid Interfaces, Chem. Soc. London, No. 2, 1972, pp. 7-17.

[8] D.H. Buckley and K. Miyoshi, Tribological Properties of Structural Ceramics, NASA Technical Memorandum 87105, Lewis Research Centre, Cleveland, Ohio, 1985.

[9] T. Kayaba and K. Kato, The Analysis of Adhesive Wear Mechanism by Successive Observations of the Wear Process in SEM, Proc. Int. Conf. on Wear of Materials, Dearborn, Michigan, 16-18 April 1979, editors: K.C.Ludema, W.A. Glaeser and S.K. Rhee, Publ. American Society of Mechanical Engineers, New York, 1979, pp. 45-56.

[10] F.P. Bowden and D. Tabor, The Friction and Lubrication of Solids, Part 2, Oxford University Press, 1964.

[11] T. Sasada, S. Norose and H. Mishina, The Behaviour of Adhered Fragments Interposed Between Sliding Surfaces and the Formation Process of Wear Particles, Proc. Int. Conf. on Wear of Materials, Dearborn, Michigan, 16-18 April 1979, editors: K.C. Ludema, W.A. Glaeser and S.K. Rhee, Publ. American Society of Mechanical Engineers, New York, 1979, pp. 72-80.

[12] Fontalvo, G.A., Humer, R., Mitterer, C., Sammt, K. and Schemmel, I., 2006. Microstructural aspects determining the adhesive wear of tool steels. Wear, 260(9-10), pp.1028-1034.

[13] Yin, X. and Komvopoulos, K., 2010. An adhesive wear model of fractal surfaces in normal contact. International Journal of Solids and Structures, 47(7-8), pp.912-921.

[14] Lijesh, K.P. and Khonsari, M.M., 2018. On the modeling of adhesive wear with consideration of loading sequence. Tribology Letters, 66(3), pp.1-11.

Be the first to comment