I'm an Erasmus Mundus Scholarship recipient in the field of Tribology of Surfaces and Interfaces. The masters program takes place in four different universities namely University of Leeds (UK), University of Ljubljana (Slovenia), University of Coimbra (Portugal) and Lulea Technical University (Sweden).

Introduction to Tribology

Table of Contents

-

Definition of Tribology.

Tribology is the science of friction, wear, and lubrication and is truly interdisciplinary. It studies the interaction of moving surfaces and every aspect related to friction, wear, lubrication, adhesion, tribo-chemistry, etc. Tribology solutions are applied in automotive industry, bearings, space, sports, food, health and biomedical, renewable energy, and other numerous fields.

-

Brief introduction to the Tribology and its fields.

The term “tribology” is derived from the Greek word ‘tribos’ [τρίβοσ] meaning ‘rubbing’ or to rub and it was invented in 1964, while exploration of friction has started well in the past sometime 50,000 B.C. when humans started using it to get fire [see history of tribology]. Ancient civilizations in Egypt and China applied lubrication principles to transport heavy stones used in their gigantic buildings. However, the first systematic studies of tribology were performed by Leonardo da Vinci – the first tribologist of the world in 1490-1500. He focused on all kinds of friction and made a distinction between sliding and rolling friction.

The importance of tribology rises due to the fact that frictional and wear losses consume energy, which otherwise could be saved. Professor Jost estimated that minimal investment [with the ratio of 1 to 50 to the outcome] in research and development of better tribological practices could save from 1% to 1.4% of gross national product [1]. Besides economic effects, tribology can be used to reduce CO2 emissions by increasing the energy efficiency and thus help to maintain our planet. Transportation industry is one of the largest energy consumers, but also CO2 emission source while being potentially largely optimized by using cutting-edge tribology solutions. Wear particles can be a source of mechanical damage in bearings, disk brakes, MEMS, but also are harmful to human health if penetrate from the atmosphere to the human body. The outcomes of the tribological research therefore can be used to solve important problems of society.

Fig-1 History of Tribology [23]

-

Different tribological fields and some points on their explanation.

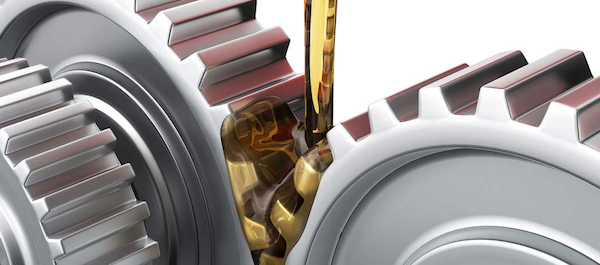

a. Classical Tribology

Wear and friction in manufacturing techniques and mechanical components like brakes, bearings, gears, wheels and clutches are the emphasis of classic tribology. Wherever the bodies are in relative motion to each other we can see friction and wear. These play a vital role in industries and requires a lot of engineering to minimise these for the long run of components. Lubricants are used in majority of the parts in automotives. These lubricants can be of mineral or synthetic origin depending on the usage and the performance. For instance, lubricants are used in gear oils, engine oils, hydraulic and transmission fluids, grease etc. They help in reduction of wear, friction, carrying away heat and corrosion protection etc. For more enhancement of lubricants several additives are added into the base oils. In bearings, tribology plays a vital role as it needs to minimise the wear and friction of the moving parts which are under relatively high pressures. When these bearings are operating at such huge pressures there’re a lot of physio-chemical process changes which might occur on the bearing surfaces which needs to be addressed to predict the wear and minimise the friction. [24]

Fig-2 Classical Tribology [30]

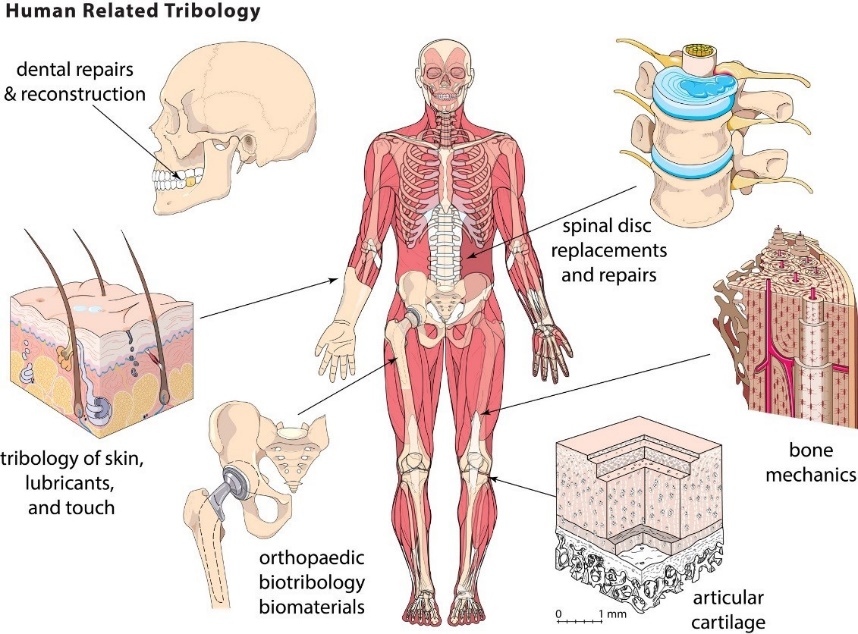

b. Bio Tribology

The term bio tribology is a combination of the phrases biology and tribology [2]. It is the application of tribology to working biological systems, such as dentistry, skin tribology, spinal disc repairs, synovial joints and corresponding replacements. The study of friction, wear and lubrication in such systems is known as bio tribology. The design and function of synovial, hip joint replacements have been investigated extensively, whereas significant investigations have been conducted on the eye in the last few years. Even though wear is not a big problem in the ocular environment, friction and lubrication are critical; this is especially true in the context of a contact lens. [3] Dentistry is undergoing an abundance of tribological studies as a consequence of its aggressive expansion and development. The major tribological issues for a dental implant are fretting corrosion as well as the fixation stability of tooth interface. [4] In biotribology, skin is among the most researched tissues. Sensory response, movement all rely on the nerve-rich skin as it is our contact with the environment. Since skin tribology is so complicated, doctors, metallurgists, physicists, scientists, and chemists must work collaboratively. [5]

Fig-3 Bio Tribology [6]

c. Green Tribology

The term green tribology has become part of the vocabulary now. Green tribology is a branch of tribology that relates specifically to maintaining an ecological balance of any potential environmental and biological impacts of the interactions between various surfaces that can occur between materials. Green tribology works to ensure that any friction and wear occurring between materials happens in an environmentally friendly manner. Researchers in the green tribology field are also looking at wind-power turbines [7], solar panels [25], and tidal turbines [8]. They are focusing on being more environmentally friendly and sustainable in the future.

Green tribology has three basic principles aimed at ensuring a limited impact on the environment and human health. These three principles are biomimetics [imitating the models, systems, and elements of nature in order to solve complex human problems] and self-lubricating materials and surfaces, biodegradable and environmentally friendly lubrication, and renewable and/or sustainable sources of energy.

Specifically, green tribology looks at minimizing friction, minimizing wear, reducing and/or eliminating lubrication, creating natural lubrication, maintaining green engineering and chemistry principles, and real-time monitoring of tribology systems. [7]

Green tribology is a fairly new concept; however, it is already playing an important role in ensuring that all industrial systems are able to function in an environmentally friendly way. Additionally, researchers are looking at methods for integrating green tribology and developing systems that are completely sustainable in terms of engineered design and energy production. Green tribology is garnering a great deal of attention to the high costs related to tribological contacts. Studies show that approximately 23% of today’s global total energy consumption is a result of inefficient performance of the tribological contacts. Of that total, approximately 20% of the energy is used to deal with friction issues and the remaining 3% is to manufacture replacements for parts worn down to due wear and other wear-related failures. [9]Adopting modern tribological techniques could minimize emissions of carbon dioxide by as much as 1,460 MtCO2 globally, saving 450,000 million Euros in the short run. In longer run, a decrease of 3,140 MtCO2 and a cost reduction of 970,000 million Euros are possible. [26]

Fig-4 Green Tribology [31]

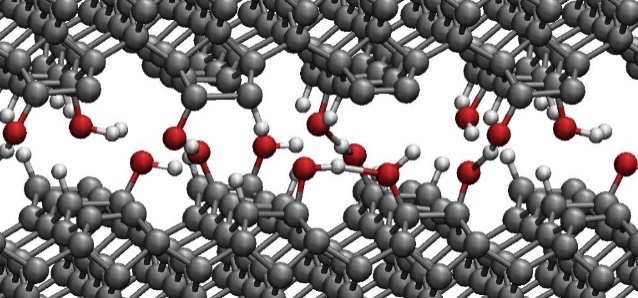

d. Nano Tribology

Nanotribology is a discipline of tribology that investigates adhesion, wear, friction and lubrication at the nanoscale level, where interactions between atoms and quantum effects are significant. Characterizing and altering surfaces for scientific and technical objectives is the purpose of this field. The development of Atomic Force Microscopy [AFM] made the investigation in the field of tribology at nano-scale level much easier. It can assist in many tribological applications on atomic scales and can measure a wide range of normal loads. Single asperity characterization can also be done using the AFM. Nano Electro Mechanical System [NEMS] are an example of implementation of nano-tribology. [27]

Friction may be decreased or improved more intensely than macroscopic level by altering the morphology of surfaces at the nanoscale. This might even lead to super-adhesion and super-lubrication. Friction and wear difficulties in micro and nano-scale systems, which are crucial owing to the relatively high surface to volume ratio, can be addressed by super lubricant coatings. Nanotribological approaches also provide a way to solve adhesion problems. [10]

Fig-5 Nano Tribology [6]

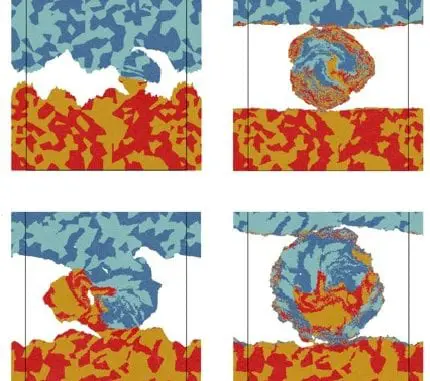

e. Computational Tribology

Computational tribology integrates fields such as fracture and contact mechanics, computational fluid dynamics [CFD] to simulate the behaviour of tribological phenomena via multi-physics simulations. In bearings, CFD helps us to investigate and predict complex interactions between lubricant flow and bearing operation. Regarding to bearing lubrication, CFD can analyse the effectiveness of lubricant supply with respect to various lubricant supply methods, bearing types and operating conditions through predicting oil flow in a bearing. [11] There’re several simulation models such as Boundary element method (BEM), Finite element method (FEM) etc which can be used to solve the complex phenomena using computational tools by taking necessary inputs and boundary conditions. Using these techniques we can simulate the lubrication regimes of a lubricant, stick-slip conditions, elasto-hydrodynamic lubrication and many more.

Fig-6 Computational Tribology [12]

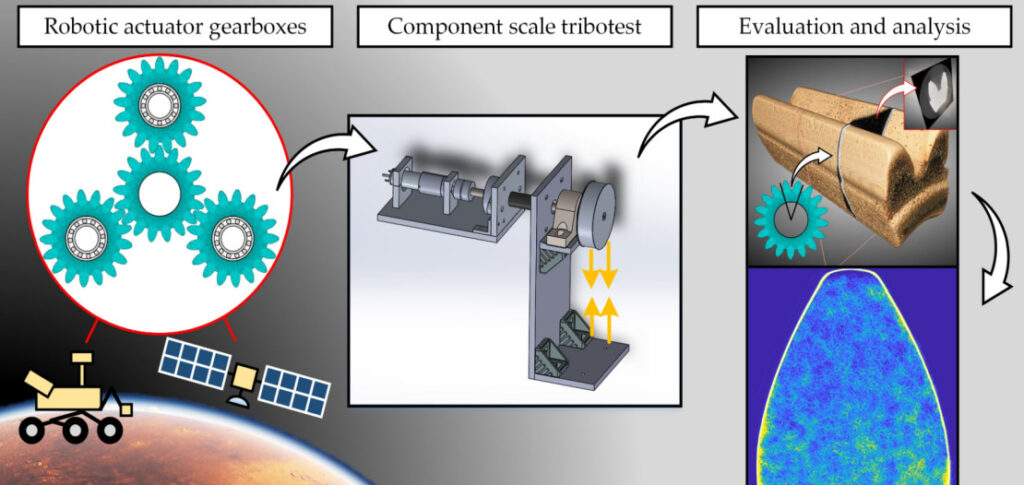

f. Space Tribology

Space tribology is the study of tribological technologies that can function in the harsh conditions of space. This necessitates lubricants with a low vapor pressure and the ability to endure severe temperature changes. [13] The environmental condition encountered by satellites, space shuttles can be harsh [varying from cryogenic to hundreds of °C temperatures], which tends to disallow the usage of liquid lubricating oils as its molecules thermally decompose at adequately high temperatures, and fluids get too viscous to flow at relatively low temperature. Solid lubrication is the only option in such conditions. In reality, both solid and fluid lubricants play vital roles; it’s just a matter of choosing the lubricant which can properly handle the anticipated working circumstances. [14]Solid lubricants of various types, such as lamellar solids, polymers and soft metals have been utilized in space. Transition metal dichalcogenides, such as molybdenum disulfide and tungsten disulfide, are examples of lamellar solids. Gold, lead, indium and silver are examples of soft metals. Polymeric materials such as polyimides and PTFE have been employed in space applications. Metal films and lamellar solids, unlike liquid lubricants, are deployed as thin films. [28]

Fig-7 Space Tribology [29]

-

Application of tribology.

The applications of tribology can be seen in numerous fields starting from classic ones to nano and space tribology. This area of application tends to grow larger with evolving technology. Tribology study has traditionally focused on designing proper lubrication of machine elements, notably bearings. Tribology also encompasses most parts of latest technology, and any process in which one material moves over the other can be influenced by it. [15]

Tribology investigation in the transportation sector has focused predominantly on dependability, assuring the safety and uninterrupted functioning of machine elements. Efficiency has grown extremely vital in recent years as a result of a greater emphasis on consumption of energy, and lubricants have gotten extremely complicated to achieve this. [15] Tribology is indeed very crucial in the manufacturing industry. Friction, for instance, enhances wear rate and the force acting on work-piece in metal-forming activities. As a result, there is increase in costs due to increased replacement of tools, tolerance loss due to fluctuations in tool dimensions, and more pressures required to form a component.

-

Future scope of Tribology.

Until recently, tribology has been a vital part of mechanical progress. As the emphasis on innovation gradually expands to nano and bio-technology, the role of tribology will become more significant. Sturdiness will become a vital criterion utilized in industry in the twenty-first century, that has not been adequately addressed in the preceding years.

Contact mechanics and tribology are currently expanding to substantially new sectors of application that are at the centre of global technology trends, such as biology [16], micro- and nano-technology [17], and healthcare [18,19,20]. Following significant and contentious debates, multiple efforts have recently been made to achieve agreement on the current status of tribology and accessible techniques [21,22]. These efforts, as well as the fast growth into emerging research fields like nanotechnology and life sciences, offer reason to believe that tribology will experience a golden era in the future years.

References:

- Jost, H.P.: Tribology micro & macro-economics: A road to economic savings, Tribology and Lubrication Technology, Vol. 61, No. 10, pp. 18-23, 2005.

- YoshikiOshida, Mechanical and Tribological Behaviors, Bioscience and Bioengineering of Titanium Materials [Second Edition], Elsevier, 2013, Pages 117-137, ISBN 9780444626257, https://doi.org/10.1016/B978-0-444-62625-7.00005-4.

- Mann, B.J. Tighe, Ocular biotribology and the contact lens: Surface interactions and ocular response, Biomaterials and Regenerative Medicine in Ophthalmology [Second Edition], Woodhead Publishing, 2016, Pages 45-74, ISBN 9780081001479, https://doi.org/10.1016/B978-0-08-100147-9.00003-1

- Zhang, X., Zhang, Y. &Jin, Z. A review of the bio-tribology of medical devices. Friction 10, 4–30 [2022]. https://doi.org/10.1007/s40544-021-0512-6

- Dowson, Duncan [2012]. Bio-tribology. Faraday Discussions, 156[], 9–. doi:10.1039/c2fd20103h

- “Modern applications of tribology.” Tribonet, 16 July 2017, https://www.tribonet.org/news/modern-applications-of-tribology/

- Nosonovsky, Michael & Bhushan, Bharat. [2010]. Green tribology: principles, research areas and challenges INTRODUCTION. Philosophical transactions. Series A, Mathematical, physical, and engineering sciences. 368. 4677-94. 10.1098/rsta.2010.0200.

- Van, Nguyen &Kuzharov, Alexander & Le, Hải& Minh, Nguyen & Huynh, Andrey &Kuzharov, [2020]. Green Tribology. 10.5772/intechopen.94510.

- “Green tribology.” Tribonet, 16 September 2019, https://www.tribonet.org/news/green-tribology/

- “Nanotribology.” Wikipedia, 6 September 2021, https://en.wikipedia.org/wiki/Nanotribology

- “CFD simulation of lubricant flow in bearings.” Tribonet, 4 October 2021, https://www.tribonet.org/news/cfd-simulation-of-lubricant-flow-in-bearings/

- “Analyzing the evolution of adhesive wear.” Tribonet, 6 May 2019, https://www.tribonet.org/news/analyzing-the-evolution-of-adhesive-wear/

- “Space Tribology.” Wikipedia, 2 February 2022, https://en.wikipedia.org/wiki/Space_tribology

- Roberts, E W [2012]. Space tribology: its role in spacecraft mechanisms. Journal of Physics D: Applied Physics, 45[50], 503001–. doi:10.1088/0022-3727/45/50/503001

- Stachowiak, G.W. How tribology has been helping us to advance and to survive. Friction 5, 233–247 [2017]. https://doi.org/10.1007/s40544-017-0173-7

- Gorb, S. N. [Ed.]. [2009]. Functional Surfaces in Biology. Springer.

- Bhushan, B. [Ed.]. [2017]. Nanotribology and Nanomechanics. Heidelberg: Springer International

- Willert, H.-G., Buchhorn, G. H., Fayyazi, A., Flury, R., Windler, M., Köster, G., et al. [2005]. Metal-on-metal bearings and hypersensitivity in patients with artificial hip joints. J. Bone Joint Surg. 87, 28–36. doi: 10.2106/jbjs.a.02039pp

- Paterson, M. [2007]. The Senses of Touch: Haptics, Affects and Technologies. Oxford: Berg.

- Li, Q. S., Lee, G. Y. H., Ong, C. N., and Lim, C. T. [2008]. AFM indentation study of breast cancer cells. Biochem. Biophys. Res. Commun. 374, 609–613. doi: 10.1016/j.bbrc.2008.07.078

- Müser, M. H., Dapp, W. B., Bugnicourt, R., Sainsot, P., Lesaffre, N., Lubrecht, T. A., et al. [2017]. Meeting the contact-mechanics challenge. Tribol. Lett. 65:4. doi: 10.1007/s11249-017-0900-2

- Vakis, A. I., Yastrebov, V. A., Scheibert, J., Nicola, L., Dini, D., Minfray, C., et al. [2018]. Modeling and simulation in tribology across scales: an overview. Tribol. Int. 125, 169–199. doi: 10.1016/j.triboint.2018.02.005

- Dowson D [1979] History of tribology. Longman,New York

- Qiu, M., Chen, L., Li, Y., Yan, J. [2017]. Friction, Wear, and Lubrication in the Bearing Application. In: Bearing Tribology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-53097-9_1

- Tzanakis, M. Hadfield, B. Thomas, S.M. Noya, I. Henshaw, S. Austen,Future perspectives on sustainable tribology,Renewable and Sustainable Energy Reviews,Volume 16, Issue 6,2012,Pages 4126-4140,ISSN 1364-0321,https://doi.org/10.1016/j.rser.2012.02.064.

- Holmberg, K., Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 5, 263–284 (2017). https://doi.org/10.1007/s40544-017-0183-5

- Bhushan B. Micro/nanotribology using atomic force microscopy/friction force microscopy: State of the art. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 1998;212(1):1-18. doi:10.1243/1350650981541859

- Jones, W R; Jansen, M J (2008). Tribology for space applications. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 222(8), 997–1004. doi:10.1243/13506501JET305

- Nyberg E, LlopartiCervelló D, Minami I. Tribology in Space Robotic Actuators: Experimental Method for Evaluation and Analysis of Gearboxes. Aerospace. 2021; 8(3):75. https://doi.org/10.3390/aerospace8030075

- “Europe’s Largest International Conference on Tribology and Lubrication.” BearingNews, 13 December 2017, https://www.bearing-news.com/europes-largest-international-conference-tribology-lubrication/

- “Green Tribology.” PCS Instruments, https://pcs-instruments.com/industry/green-tribology/

Be the first to comment