I'm an Erasmus Mundus Scholarship recipient in the field of Tribology of Surfaces and Interfaces. The masters program takes place in four different universities namely University of Leeds (UK), University of Ljubljana (Slovenia), University of Coimbra (Portugal) and Lulea Technical University (Sweden).

Surface Enhancement: Mechanical Methods

Table of Contents

1. Introduction:

The techniques used to modify the surface properties of materials are classified into various categories. Mechanical methods of surface enhancement are one of the many surface modification techniques that are now being used to improve the surface characteristics of the materials.[1] They are used to improve a surface’s characteristics by modifying its morphology and roughness. The surface of a material is strengthened due to plastic deformationas when a material is deformed plastically more dislocations are formedwhich impedes further movement which leads to increase in strength of materials.Micro-machining, polishing, grinding, and shot peening are conventional mechanical surface modification techniques that entail physically modifying, or removing material from the surface. Achieving certain surface roughness and topographies, removing contaminants from surface, and enhancing adhesion are the primary goals of mechanical modification. These techniques are usually used in combination with other procedures as they solely cannot completely improve the surface properties of the material. [2-3] Mechanical surface enhancements such as micro-machining, surface grinding, shot peening and abrasive blasting are discussed below.

2. Micro-machining:

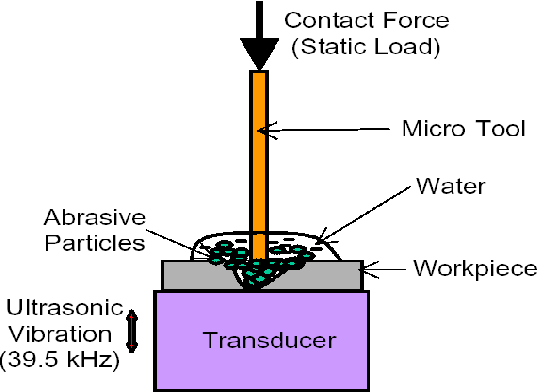

In micro-machining process, the material is removed from the surface as chips or melting and vaporisation. Micro-milling, micro-electric discharge machining, ultrasonic machining (fig-1), micro-electric chemical machining and other methods are often used to enhance the surfaces.Typically, this machining is done following the bulk machining procedure such as etching due to the fact that this removes the unwanted substrate. [4]

Fig-1 Micro-machining process [13]

3. Surface Grinding:

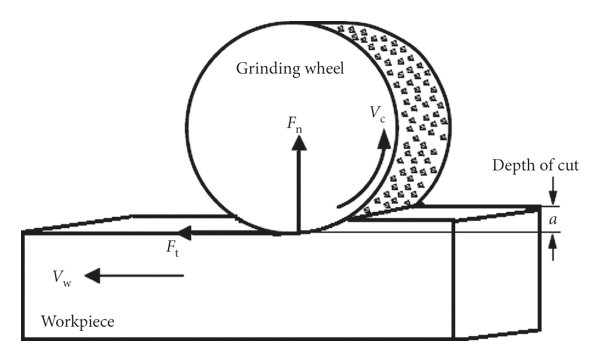

Surface grinding is a finishing technique that employs a rotating wheel of abrasives to smoothen the flat surface of metals as well as non-metals and give them a more polished appearance by eliminating the oxide layer and other contaminants as shown in fig-2. Additionally, this will produce the necessary surface for a practical purpose.Results indicated that roughness and hardness of the surface increased as the size of grinding particles increased. [5] For instance according to studies, grinding of steels would induce cold working and lead to the modifications such asa variation in surface roughness, the development of a layer of fine martensitic grains, residual stress, work-hardening etc. [6]

Fig-2 Surface grinding process [14]

4. Shot Peening/Shot blasting:

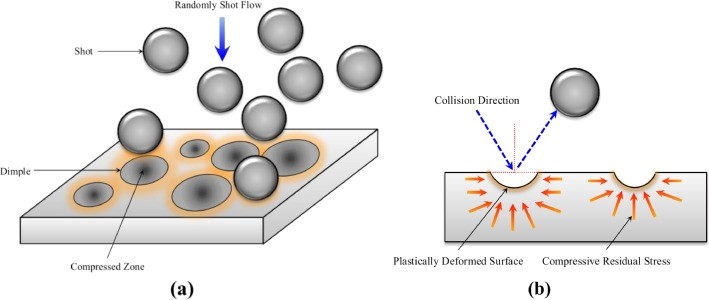

Shot peening also referred as shot blasting is a work-hardening technique which is used for fatigue prevention (since tensile stresses are now replaced with compressive stresses and they help in minimizing fatigue) thus leading to an increase in the life-cycle of a component. It is also used to eliminate oxides as well as other contaminants from the surface of other material. [7]

Round particles often referred to as shots are blasted against a material during this process, which helps in eliminating impurities and improving surface finish. It creates dimples on the surface under which compressive stresses act. These residual compressive stresses help in strengthening and protecting the material from fatigue, corrosion, galling and erosion from cavitation as depicted in fig-3. A crucial choice in the shot peening process is the kind of shot media to be deployed. The amount of surface removal will depend on the shot material’s hardness and size. The efficiency of the shot blasting procedure will also depend on the material being treated. When choosing the shot substance and size, we consider the material composition of the surface being shot blasted.[8]

Fig-3 Schematic of shot peening process [9]

Shot blasting is a type of abrasive blasting like sandblasting. Sandblasting and shot blasting are primarily distinguished by the use of round particles as abrasives. Typically, a centrifugal blast wheel for acceleration isused in shot blasting and the exclusive use of compressed air in sandblasting. There are several shot peening techniques such as ultrasonic peening, laser peening, and wet peening which do not use any media.

The type of propulsion and the consequent velocity of the shot particles are crucial components of the shot peening procedure. A recovery system is a common addition to this process. The shot that has already been discharged and collided with the surface being treated will be recovered by the shot blast recovery system and sent to the propelling device to be used yet again. A vacuum is often used to carry out this recovery.Nearly every sector that uses metal today, including aerospace, automobile, shipbuilding, railways, foundry, and, construction makes use of shot blasting. Shot blasting’s effectiveness is significantly superior to that of its alternatives, such as laser rust removal and laser surface cleaning. [10]

The advantages of this technique are:

- It helps in improving the strength and fatigue resistance of complex geometric parts.

- The method has undergone extensive study and quality standards to assure its efficacy. It is also well-known and cost effective. Additionally, the material and tools are easily accessible.

The dis-advantages of this technique are:

- Pre-processing may be necessary in specific circumstances, such as clearing of dust or metal rust.

- Shot peening with high intensities require particular caution since it can leave the surface with unwanted stress or roughness

- It’s not uncommon for the process to end with an average surface roughness value.

5. Abrasive blasting:

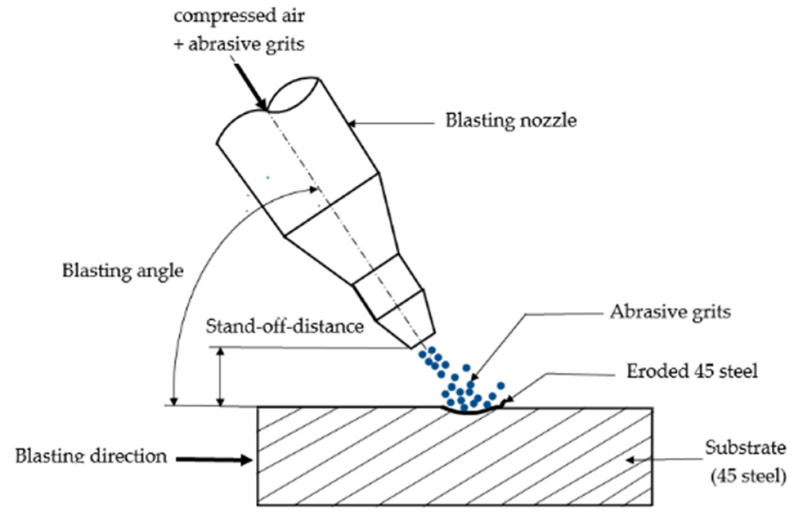

Abrasive blasting removes flaws, paint, corrosion, and other impurities from the material surface. It is a crucial stage in the preparation of surface coating process since it cleans the substrate and prepares it to adhere properly with the base as depicted in fig-4. The majority of abrasive media are inexpensive and reusable. Since it cleans surfaces more quickly and effectively, it is more economical to use. It works well to remove rust from metallic surfaces and they can be effectively prepared for coating through this process. During this, temperature and humidity are extremely crucial since the metal’s contact to the atmosphere renders it vulnerable to oxidation. [11]

Fig-4 Abrasive blasting [12]

So, we can conclude by stating that there’re various mechanical methods of surface enhancement and depending upon the type of application and requirements we need we can identify the particular process of interest for us.

6. References:

- Mitra S.K., Saha A.A. (2008) Surface Modification, Methods. In: Li D. (eds) Encyclopedia of Microfluidics and Nanofluidics. Springer, Boston, MA. https://doi.org/10.1007/978-0-387-48998-8_1503.

- Mozetič M. Surface Modification to Improve Properties of Materials. Materials (Basel). 2019 Jan 31;12(3):441. doi: 10.3390/ma12030441. PMID: 30709009; PMCID: PMC6384733.

- Cavalu, Simona &Antoniac, Iulian & Mohan, Aurel George & Bodog, Florian &Doicin, Cristian & Mates, Ileana &Ulmeanu, Mihaela-Elena &Murzac, Roman &Semenescu, Augustin. (2020). Nanoparticles and Nanostructured Surface Fabrication for Innovative Cranial and Maxillofacial Surgery. Materials. 13. 10.3390/ma13235391.

- Jain VK, Patel DS, Ramkumar J, et al. Micro-machining: An overview (Part II). Journal of Micromanufacturing. 2022;5(1):46-73. doi:10.1177/25165984211045244

- Ligong Ling, Lei Luo, Fengsheng Liu, Effects of grinding treatment on surface properties and deformation microstructure in alloy 304L, Surface and Coatings Technology, Volume 408, 2021, ISSN 0257-8972, https://doi.org/10.1016/j.surfcoat.2021.126850.

- S Byun, N Hashimoto, K Farrell, Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels, Acta Materialia, Volume 52, Issue 13, 2004, Pages 3889-3899, ISSN 1359-6454, https://doi.org/10.1016/j.actamat.2004.05.003.

- Tiansheng Wang, Jinku Yu, Bingfeng Dong, Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 1Cr18Ni9Ti stainless steel, Surface and Coatings Technology, Volume 200, Issues 16–17, 2006, Pages 4777-4781, ISSN 0257-8972, https://doi.org/10.1016/j.surfcoat.2005.04.046.

- John M, Kalvala PR, Misra M, Menezes PL. Peening Techniques for Surface Modification: Processes, Properties, and Applications. Materials (Basel). 2021 Jul 9;14(14):3841. doi: 10.3390/ma14143841. PMID: 34300760; PMCID: PMC8307355.

- ErfanMaleki, OkanUnal, AuezhanAmanov, Novel experimental methods for the determination of the boundaries between conventional, severe and over shot peening processes,Surfaces and Interfaces, Volume 13, 2018, Pages 233-254, ISSN 2468-0230, https://doi.org/10.1016/j.surfin.2018.09.003.

- “Shot Blasting.” Metal supermarkets, 23 Jun 2020, https://www.metalsupermarkets.com/what-is-shot-blasting/

- “Abrasive Blasting.” Polygon, https://www.polygongroup.com/en-US/blog/benefits-of-using-abrasive-blasting-before-surface-coating/

- Gbenontin BV, Kang M, Ndiithi NJ, Nyambura SM, Awuah E, Zhang Y. Effect of Grit Blasting and Polishing Pretreatments on the Microhardness, Adhesion and Corrosion Properties of Electrodeposited Ni-W/SiC Nanocomposite Coatings on 45 Steel Substrate. Crystals. 2021; 11(7):729. https://doi.org/10.3390/cryst11070729

- Cherku, Sreenidhi, Murali M. Sundaram and Kamlakar P. Rajurkar. “Experimental study of micro ultrasonic machining process.” (2008).

- Amon, Gasagara&Jin, Wu-Yin &Uwimbabazi, Angelique. (2020). Modeling of Vibration Condition in Flat Surface Grinding Process. Shock and Vibration. 2020. 1-12. 10.1155/2020/3069895.

Be the first to comment