I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Wear debris

Table of Contents

Definition:

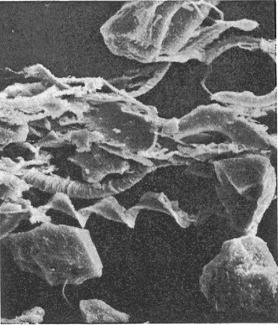

The wear debris are the particles that regenerated at the interface of the two contacting surfaces in motion due to the rubbing of the interfacial layers on the material surface. The wear debris are the characteristic feature of any type of wear, however, it is different in different wear types. The wear debris differs in various sizes and shapes depending on the type of contact and the force encountered at the contact interface. The wear debris or particles are mainly spherical, cylindrical, needle-like, etc. These debris present in the contact interface affects the tribological properties of the surface such as the friction and rate of wear [1]. So, it is important to study these structures and its properties to improve the frictional properties of the surfaces. The wear debris in case of cutting wear is shown in Fig- 1.

Fig-1 Wear debris in case of cutting wear [2].

Wear debris production:

The elements operating in any contact conditions involve the friction at its surface which in turn generates the heat and causes wear on the surface. These factors i.e., friction and wear determine the life of any mechanical components in operation, therefore it is essential to study these factors and the conditions influencing these factors. There are various types of wear mechanisms involved in wear debris production, such as; adhesion, abrasion, fretting, oxidation, corrosion, erosion, etc. These wear mechanisms produce the debris according to the type of the damage i.e., through mechanical, physical, and chemical means. Also, the wear debris formation depends on the type of lubricant contact i.e., boundary and mixed lubrication regimes.

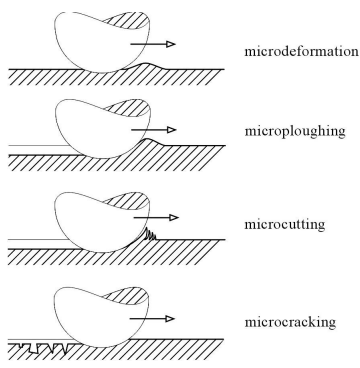

The detachment of the wear debris from the contact surface of the two materials takes place in different ways, it depends on the type of materials, type of sliding conditions, etc. The detachment of the wear particles in case of mechanical means is due to the formation of the micro-stresses that has resulted from the applied load. The detachment also depends on other mechanisms such as micro-cutting, non-elastic deformation, break-off, failure due to fatigue, etc. four different types of wear debris production are shown in Fig- 2. The four different types of these micro-mechanisms for the wear debris formation includes the micro-deformation, micro-ploughing, micro-cutting and micro-cracking.

Fig-2 Wear debris producing mechanisms [1].

Morphology of wear debris:

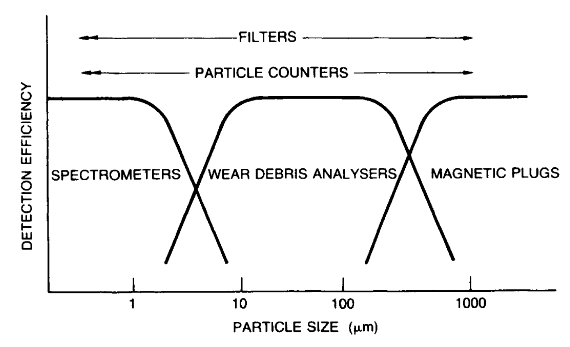

The morphology of the wear debris is one of the important properties that must be studied to improve the tribological properties on the surfaces. There are many studies over many decades where researchers have studied about the different morphological features of the wear debris such as the size, shape, concentration, etc [4]. however, it is very difficult to categorize these features for the defined measurements. The morphology of the wear debris can also be characterized using the type of dyes used for coloring [3], which helps in identifying the differences from the parent body. The efficiency of wear debris monitoring methods is shown in Fig- 3.

Fig-3 The relative efficiency of various wear debris monitoring methods [2].

Studies based on the various optical and scanning electron microscopes have shown that the shapes of the wear debris cannot have the definite shape [5]. Hence, there were many shapes identified for the wear debris which led to the following classification:

- In this classification, the wear particles or debris are classified mainly into flakes and non-flakes. In case of the flakes the debris has the uniform thickness and in case of the non-flakes the debris can be powders, cylinders, ribbons, irregular chunks etc.

- In another classification, they are divided based on the long fibrous and thin platelet, these types are usually found in the case of lubricated samples.

- Further, they can also be classified into granular particles, long sheet-like, roll and rope like particles.

Properties of wear debris:

Mechanical properties:

The mechanical properties of the wear debris mainly include the properties like hardness, tension, compression, bending, shear, torsion, creep, fatigue, etc. These properties of the wear debris influence the stress and strains on the interface of the materials contact resulting in changes in the frictional behavior of the materials. Hence, studying these mechanical properties of the wear debris after the wear test is important to understand its influence on the changes in friction and wear rate [6].

Physical properties:

The physical properties of the wear debris mainly include their material composition, density, microstructure, thermal conductivity, thermal expansion, melting point, etc. These properties are mainly dependent on the parent body from which the wear debris is formed. Hence there are many wear particles formed from the materials like metals, metal oxides, metal alloys, plastics, etc.

Chemical properties:

The chemical property of the wear debris is one of the important factors that have to be considered due to the different chemical compositions of the materials in contact. When the wear debris is formed they could be influenced by the chemical properties of the different materials in contact which would be a fine-grained structure. So, the chemical properties are very important to understanding the wear debris in influencing the frictional properties at the interface [7].

Role of wear debris:

Modification of friction and wear

The main role of wear debris formation in the interface of the two materials in the sliding contacts is the varying the friction and wear behaviour. The presence of the wear particles in the interface could be predicted by change in the coefficient of friction (COF) values during the tribological test on any materials. This change in the COF values vary both positively [7] and negatively [8] in the presence of the wear debris at the contact medium. It is found that the wear particles entrapped in the sliding contact could increase the COF values. The COF values change differently due to the presence of the wear debris and it reaches the constant values when the number of wear debris formation at the contact interface is equal to the number of debris leaving the interface. Also, it is studied that the wear debris of the spherical and cylindrical shapes have shown in decreasing the COF values at the interface by acting as the rollers and solid-lubricants at the interface in the absence of lubrication.

Wear debris research:

The research focusing on study of properties of wear debris is a very huge area in the field of tribology. The properties of the wear debris change for different materials, different contacts and at different lubricated conditions. So, it is important to study these properties based on the applications where the tribological properties of the materials in contact can be improvised. M. Varenberg et.al., studied the role of wear debris in the fretting wear they textured the surface of the material contact to create a path for the wear debris escape. They also found that this debris plays an important role in reducing the friction at adhesive wear mechanisms [10]. JA. Savio et.al., have studied the size and shapes of the wear debris in biomaterials, the shapes such as granules, splinters, and flakes were identified that influenced the material properties [11].

References:

[1] Zmitrowicz, A., 2005. Wear debris: a review of properties and constitutive models. Journal of theoretical and applied mechanics, 43.

[2] Neale, M.J., 1995. The tribology handbook. Elsevier.

[3] Myshkin N.K., Kong H., Grigoriev A.Ya., Yoon E.-S., 2001, The use of colour in wear debris analysis, Wear, 250-251, Part 2, 1218-1226

[4] Roylance B.J., Wang G., Bovington C.H., 1992, The determination of particle morphological parameters to assist in elucidation of wear process, [in:] Wear Particles: From the Cradle to the Grave, D. Dowson et al. (Edit.), Elsevier, Amsterdam, 75-79

[5] Roylance B.J., Williams J.A., Dwyer-Joyce R., 2000, Wear debris and associated wear phenomena-fundamental research and practice, J. Eng. Tribology, Proc. Inst. Mech. Eng., 214, J1, 79-105

[6] Sheasby J.S., 1983, Direct observation of dry wear, Wear, 89, 2, 173-183

[7] Wirth A., Eggleston D., Whitaker R., 1994, A fundamental tribochemical study of the third body layer formed during automotive friction braking, Wear, 179, 1-2, 75-81

[8] Zanoria E.S., Danyluk S., McNallan M.J., 1995, Formation of cylindrical sliding-wear debris on silicon in humid conditions and elevated temperatures, Tribology Transactions, 38, 3, 721-727

[9] Kuwahara K., Masumoto H., 1980, Influence of wear particles on the friction and wear between copper disk and pin of various kinds of metal, Lubrication Engineering, 36, 6, 362

[10] Varenberg, M., Halperin, G. and Etsion, I., 2002. Different aspects of the role of wear debris in fretting wear. Wear, 252(11-12), pp.902-910.

[11] Savio Iii, J.A., Overcamp, L.M. and Black, J., 1994. Size and shape of biomaterial wear debris. Clinical Materials, 15(2), pp.101-147.

Be the first to comment