Administration of the project

New insight into the Fischer-Tropsch reaction

By Dr. Neil Canter, Contributing Editor | TLT Tech Beat February 2024

Experimental work identifying that the reaction exhibits an oscillation effect was verified by theoretical analysis.

HIGHLIGHTS

• Insight into the Fischer-Tropsch reaction revealed that the process varies over specific time frames and temperatures by virtue of an oscillation effect.

• The reaction slows down as the temperature increases because the two reactant gases (hydrogen and carbon monoxide) lose contact with the catalyst surface. Once this occurs, the reaction temperature declines enabling the reactant gases to enrich on the catalyst surface leading to an increase in product conversion and closure of the oscillation cycle.

• If the ratio of hydrogen to carbon monoxide is varied, this impacts the product mix. At a low ratio, propylene (and higher homologues) that contains smaller levels of hydrogen predominate while at high ratios, more hydrogenated species such as propane and methane predominate.

The growing demands for high performance lubricants are leading to the development of improved base stocks that are prepared by synthetic pathways as compared to traditional crude oil processing. An example of a base stock that is prepared through synthetic processing is polyalphaolefins (PAOs).

Another base stock that is produced through a chemical process known as the Fischer-Tropsch reaction has been identified as a gas-to-liquid (GTL) base stock. In this process, two gases, carbon monoxide and hydrogen, are reacted to produce liquid hydrocarbons, including those that have sufficient viscosity to be used as base oils.

A previous TLT article1 discusses the manufacture of GTL base stocks. The Fischer-Tropsch process yields mixtures of hydrocarbon liquids and waxes that can be used to produce naphtha and diesel fuel that have extremely low levels of sulfur and nitrogen-based impurities. Hydroisomerization of the waxes then leads to the manufacture of base stocks that also are low in sulfur, high in viscosity index and exhibit excellent oxidative and thermal stabilities. Economics has restricted the availability of GTL base stocks since they were first introduced.

The Fischer-Tropsch reaction was discovered in 1925 and utilizes cobalt or iron catalysts to produce hydrocarbons at temperatures between 200 °C and 350 °C and pressures between one and several tens of atmospheres. While the reaction has been known for about 100 years, there is no consensus on its mechanism.

Norbert Kruse, Voiland Distinguished Professor in Washington State University’s Gene and Linda Voiland School of Chemical Engineering and Bioengineering in Pullman, Wash., says, “The currently accepted mechanism involves a ‘carbide-type’ mechanism in which carbon-carbon bond coupling between surface hydrocarbon fragments (methylene or methylidyne) takes place. This theory states that carbon-carbon coupling on the surface of either an iron or cobalt catalyst produces a species that upon hydrogenation yields hydrocarbons. The problem with this approach is that it does not account for the synthesis of oxygenated products such as long-chain alcohols and aldehydes.”

Experimental research produces evidence that a carbon monoxide insertion mechanism is more likely. Kruse says, “This mechanism accounts for the formation of oxygenate products and water during the reaction. One of the concerns about carbon monoxide insertion on the metal catalyst surface is the energetic and steric requirements of a quasi-concerted dissociation and formation of bonds in the target species of the insertion.”

Kruse and his colleagues initiated experimental and theoretical research that has provided more insight into the mechanism of the Fischer-Tropsch reaction.

Oscillating reaction

The researchers conducted experimental work using a gradient-free, fixed-bed flow reactor to enable reactor response to be monitored as a function of time. The catalyst consisted of cerium oxide on cobalt metal. Kruse says, “We studied the transient kinetics when the reactor was switched from hydrogen flow to activate the catalyst to the introduction of the starting materials hydrogen and carbon monoxide. Once the reaction was initiated, we found that the temperature of the process oscillated over time. After initial concern about the reaction setup, this oscillation effect was replicated consistently leading to the conclusion that the Fischer-Tropsch reaction does not occur at a single temperature but varies over specific time frames and temperatures.”

This oscillation behavior changes as the ratio of hydrogen to carbon monoxide varies from 1 to 12. Increasing the ratio results in a decrease of the oscillation period from approximately 340 to 230 seconds and decreases the amplitude of the temperature change from 7 to 1 Celsius degree.

The researchers determined that the reaction, which is strongly exothermic, slows down as the temperature increases because the two reactant gases lose contact with the catalyst surface. As this occurs, the reaction temperature declines enabling the reactant gases to enrich on the catalyst surface leading to an increase in product conversion and closure of the oscillation cycle.

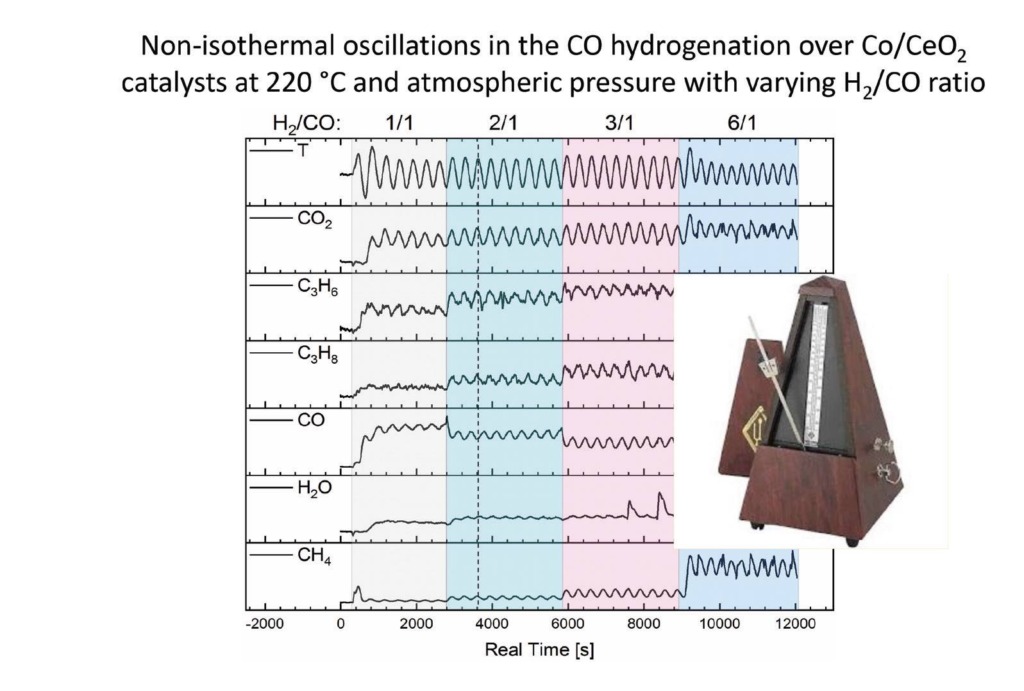

Changing the reactant ratios also impacts the product mix. Figure 3 shows the concentration of carbon dioxide (CO2), propylene (C3H6) and propane (C3H8), as examples for chain-lengthened product formation. Carbon monoxide (CO), water (H2O) and methane (CH4) formed at varying ratios of hydrogen (H2) to carbon monoxide when the Fischer-Tropsch reaction is conducted at 220 °C under atmospheric pressure. At low ratios of hydrogen to carbon monoxide, species such as propylene (and higher homologues) that contain smaller levels of hydrogen predominate. But once the ratio of hydrogen to carbon monoxide increases, more hydrogenated species such as propane and methane become the major products formed.

The researchers took the initial experimental work and had a theoretical analysis conducted that modeled the flow of hydrogen and carbon monoxide onto the catalyst, under deliberately imposed temperature oscillations, using the carbon monoxide insertion mechanism. Kruse says, “The theoretical analysis duplicated the results achieved experimentally.”

Kruse provided a detailed analysis of the mechanism. He says, “Carbon monoxide inserts initially into a hydroxyl radical to form a formate species. At this point, partial hydrogenation generates a methoxy species, which upon total hydrogenation produces methane and water. Lengthening the carbon chain is accomplished by insertion of a second carbon monoxide molecule producing an ethoxy species after partial hydrogenation that is eventually converted after further hydrogenation to the hydrocarbon, ethane or the alcohol, ethanol.” The carbon chain can continue to be extended in this manner to eventually form longer hydrocarbons suitable as lubricant base stocks.

Kruse indicates that water formation takes place at a late stage of the Fischer-Tropsch reaction when hydrocarbon chain-lengthening is engaged. Data in Figure 3 shows this occurring and that water formation increases at higher ratios of hydrogen to carbon monoxide.

Figure 3. Temperature (T) of the Fischer-Tropsch reaction varies over time, which is an indication of the oscillation process. The mixture of products produced in the Fischer-Tropsch reaction varies with the ratio of hydrogen (H2) to carbon monoxide (CO). At low ratios of hydrogen to carbon monoxide, olefins such as propylene (C3H6) predominate. Once the ratio increases, more hydrogenated species such as propane (C3H8) and methane (CH4) become the major products formed. Water (H2O) formation occurs at the late stages of the Fischer-Tropsch reaction. Figure courtesy of Washington State University.

Cerium oxide’s role in catalyzing the reaction is uncertain. Kruse speculates, “We believe the reaction may be occurring at the interface between the cobalt metal and the cerium oxide. The fact that the valence state of cerium can fluctuate between the +4 and+3 valence probably enhances the catalysis.”

Future work will involve elucidation of the Fischer-Tropsch reaction mechanism and examination of other catalyst systems to determine if the oscillation mechanism can be detected. Kruse says, “We also are interested to find out if other reactions independent of Fischer-Tropsch also undergo self-oscillation.”

Additional information can be found in a recent article2 or by contacting Kruse at [email protected].

REFERENCES

1. Whitby, R. (2015), “GTL base oils,” TLT, 71 (11), p. 128. Available here.

2. Zhang, R., Wang, Y., Gaspard, P. and Kruse, N. (2023), “The oscillating Fischer-Tropsch reaction,” Science, 382 (6666), pp. 99-102.

Neil Canter heads his own consulting company, Chemical Solutions, in Willow Grove, Pa. Ideas for Tech Beat can be submitted to him at [email protected].

Be the first to comment