I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Stick-slip Phenomenon

Table of Contents

Introduction

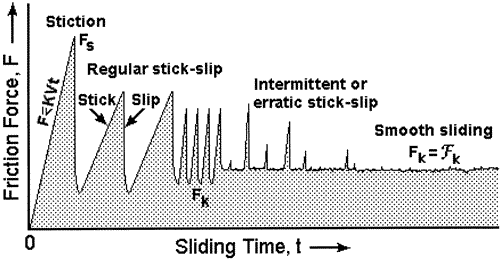

The phenomenon of stick-slip involves the dynamic interaction between two surfaces, where they alternately stick together and then slide over one another, leading to fluctuations in the force of friction between them. In general, when two surfaces are at rest, the force required to initiate movement is higher than the force required to sustain it. Once the applied force surpasses the threshold of static friction, the friction reduces to a lower level known as kinetic friction, resulting in a sudden increase in the velocity of the movement. This behavior arises from the difference in friction coefficients between static and kinetic states and can lead to interesting and sometimes unpredictable movements in various systems [1].

Figure-1 Concept of Stick slip in friction force v/s sliding time graph [2]

Stribeck curve and Stick-slip phenomenon

Stick-slip behavior is closely related to the concept of the Stribeck curve. Stick-slip behavior primarily occurs in the boundary and mixed lubrication regimes. As the system transitions from the boundary to the hydrodynamic regime (increasing Stribeck number), the stick-slip motion tends to diminish, and the friction becomes more stable and consistent. Therefore, understanding the Stribeck curve and its lubrication regimes is crucial in controlling and mitigating stick-slip phenomena in sliding contact systems by selecting appropriate lubricants and operating conditions [3].

Figure-2 Stick slip phenomenon in liquid lubricants at a contact interface [2]

Stick-slip phenomenon in different machinery parts

Linear motion in machinery is not continuous like radial bearings. In linear bearings, the motion must stop at the end of the guideway and then return in the opposite direction. This stop-and-go movement leads to linear recirculating bearings spending more time in what is known as the mixed-lubrication zone, which makes them susceptible to a phenomenon called stick-slip. With recirculating bearings, when motion starts, lubrication is drawn into the contact area between the two surfaces. This reduces the direct contact between the surfaces and causes friction forces to decrease. As the speed increases, the lubricant film increases, further reducing friction. However, beyond a certain point, friction starts to rise again, generating viscous drag. Therefore, using the correct type and amount of lubrication for recirculating bearings is crucial to avoid issues.

Plain bearings can also experience stick-slip due to higher friction coefficients when sliding (rather than rolling) occurs. To minimize stick-slip in plain linear bearings, it is essential to ensure that the bearings are adequately spaced, following the 2:1 rule or ratio. When motion starts in either recirculating or plain bearings, there is a transition from higher static friction to lower dynamic friction. This transition can cause the system to overshoot its target position and negatively impact positioning accuracy. However, with proper design of plain bearing systems and appropriate lubrication for recirculating bearings, the effects of stick-slip can be minimized [4].

Figure-3 Stick slip phenomenon in bearings [5]

In conclusion, recent advancements in both experimental and theoretical studies have provided valuable insights into the intricate phenomenon of stick-slip sliding. The experimental findings, particularly those involving smooth surfaces and liquid lubricants, align well with the concept of “rate and state” dependent models, which consider velocity and time-dependent phase transitions for stick-slip friction. Remarkably, these observations suggest that distance-dependent models or classical models based on negative friction force-velocity profiles were not necessary to explain the behavior of such idealized systems. These advancements represent a significant step towards comprehending the underlying mechanisms governing stick-slip sliding.

Reference

[5] https://www.sciencedirect.com/topics/engineering/slip-stick-effect

Be the first to comment