I am currently working as a Postgraduate Researcher at the University of Leeds, where I am actively involved in research activities. Prior to this, I successfully completed my master's degree through the renowned Erasmus Mundus joint program, specializing in Tribology and Bachelor's degree in Mechanical Engineering from VTU in Belgaum, India. Further I handle the social media pages for Tribonet and I have my youtube channel Tribo Geek.

Tribology of carbon nanotubes

Table of Contents

Introduction

In recent years, carbon nanotubes (CNTs) have emerged as one of the most promising materials due to their extraordinary properties. With ultrahigh strength and modulus, as well as anisotropic electrical conductivity, CNTs possess unique characteristics that set them apart from conventional materials. These cylindrical carbon structures have the potential to revolutionize various industries by serving as building blocks for advanced nanocomposites. By incorporating CNTs into a matrix, remarkable property improvements can be achieved in the resulting nanocomposite materials. This introduction explores the fascinating world of CNT-based nanocomposites and their potential applications in diverse fields, highlighting the significant role played by CNTs in enhancing material performance and functionality [1].

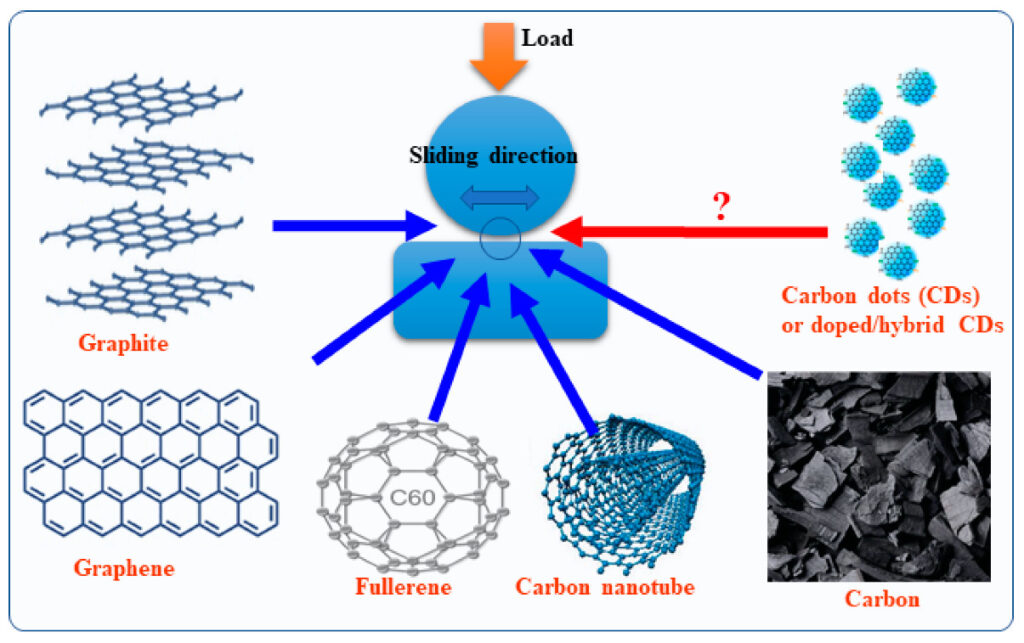

Fig-1 Different structures of carbon atom [2]

The incorporation of CNTs and graphene in Metal Matrix Composites (MMCs) holds great potential for advancing various fields of engineering and technology. The exceptional properties of CNTs and graphene, including their mechanical strength, electrical conductivity, and thermal conductivity, make them ideal candidates as reinforcing fillers in MMCs. These nanomaterials can effectively enhance the mechanical performance, electrical conductivity, and magnetic properties of the composites, enabling the development of advanced structural components and functional devices. Furthermore, the unique self-lubricating properties offered by CNTs and graphene make them particularly intriguing for applications in which reducing friction and wear are crucial, such as in aerospace, automotive, and energy systems. The combination of these nanomaterials with metallic matrices opens up new avenues for the creation of next-generation composites with improved performance and versatility [3].

CNT structure

When a sheet of carbon atoms is rolled, it gives rise to CNTs with different structures. The smallest type, called single-walled carbon nanotubes (SWCNTs) with a diameter of around 1nm. On the other hand, there are double-walled and multi-walled nanotubes, formed by rolling multiple carbon sheets, with diameters ranging from 4 to 20nm. CNTs possess distinctive mechanical and physical properties, along with lubricating characteristics. These exceptional attributes position them as promising candidates for reinforcement in metallic matrices. By incorporating CNTs into a metal matrix, the properties of materials can be enhanced, including high-temperature stability, increased strength and stiffness, superior electrical and thermal conductivity, and improved performance of industrial metal components. This makes CNTs a valuable option for advancing materials and optimizing the performance of various industrial applications [4].

Fig-2 Carbon nanotube structures [5]

CNTs – Tribological challenges

SWCNTs show promise as additives for coatings on Si (silicon) surfaces, especially for applications requiring strong wear resistance. By enhancing the adhesion strength between SWCNTs and the polymer matrix, issues like peeling-off or delamination of the coating can be mitigated, leading to improved wear resistance. In contrast to SWCNTs-reinforced coatings, the addition of MWCNTs (Multi-Walled Carbon Nanotubes) in coatings has shown reduced friction and wear. This can be attributed to the outstanding self-lubricating properties and load-bearing effects of MWCNTs. The incorporation of MWCNTs into coatings enables them to act as effective lubricants, reducing friction and providing excellent load-bearing capabilities. As a result, coatings with MWCNTs exhibit improved performance in terms of reduced friction and wear compared to their SWCNTs-reinforced counterparts [6].

Fig-3 Carbon forms in providing the lubrication for tribological interface [7]

Reference

[5] https://tuball.com/articles/single-walled-carbon-nanotubes

Be the first to comment