Administration of the project

Nanotribology

What is Nanotribology?

Nanotribology or molecular tribology is one of the most significant components of tribology which is concerned with atomic and molecular interaction at a nanoscale, occurring upon the frictional contact of materials or lubrication. Nanotribology is defined as a fundamental research field of tribology viewed from the perspective of atoms and molecules (reference). The word Nanotribology was introduced for the first time in a paper by J. Krim, D. H. Solina, and R. Chiarello, “Nanotribology of a Kr monolayer: A quartz-crystal microbalance study of atomic-scale friction”, Phys. Rev. Lett. 66, 181 – Published 14 January 1991 . This part of tribology is concerned with the characterization and modification of the interacting surfaces in both scientific and technological manner. Atomic force microscopy and other surface analysis methods have enlarged the possibility to investigate friction and wear phenomena at the nano-Newton/molecular level. Increase of computational power made it possible to research friction by molecular dynamic simulations of sliding surfaces and to investigate the atomic scale contact mechanisms. These advances provided the impetus for research aimed at developing a fundamental understanding of the nature and consequences of the interactions between materials on the atomic scale, and to guide the design efforts in industrial applications. Thus they have led to the appearance of the new field of nanotribology and nanomechanics (Bhushan, 2007) .

The term tribology was introduced in 1964. Until 1980s the field was dominated by macroscopic friction and wear studies which aimed at prolongation of the wear lifetime of components and reduce friction losses. These studies were typically required for macroscopic machines, such as bearings, engines, etc. Since early 1980s, new applications started to emerge. Development of hard drives, Microelectromechanical Systems (MEMS)/ Nanoelectromechanical Systems (NEMS) and biodevices required detailed understanding of the tribological processes on smaller scales. The field of nanotribology has grown in the last 30 years, but it is still evolving rapidly and is taking the center stage in tribology. New industrial applications continue to emerge and pose challenges in the field of nanotribology. The micro/nanotribological studies are needed to develop fundamental understanding of interfacial phenomena on a small scale and to study interfacial phenomena involving ultrathin films (as low as 1–2 nm) and in micro/nanostructures, both used in magnetic storage systems, micro/nanoelectromechanical systems (MEMS/NEMS) and other industrial applications. The components used in micro- and nanostructures are very light (on the order of few micrograms) and operate under very light loads (smaller than 1 mg to a few milligrams). As a result, friction and wear (on a nanoscale) of lightly loaded micro/nanocomponents are highly dependent on the surface interactions (few atomic layers). These structures are generally lubricated with molecularly thin films. Micro/nanotribological techniques are ideal to study the friction and wear processes of ultrathin films and micro/nanostructures.

Tools and measurements techniques in nanotribology

Clearly, the research in the field of nanotribology requires high resolution measurements. The probe-based microscopes, such as scanning tunneling, atomic force and friction force microscopes and the surface force apparatus are the most common tools for nanoscale tribology studies.

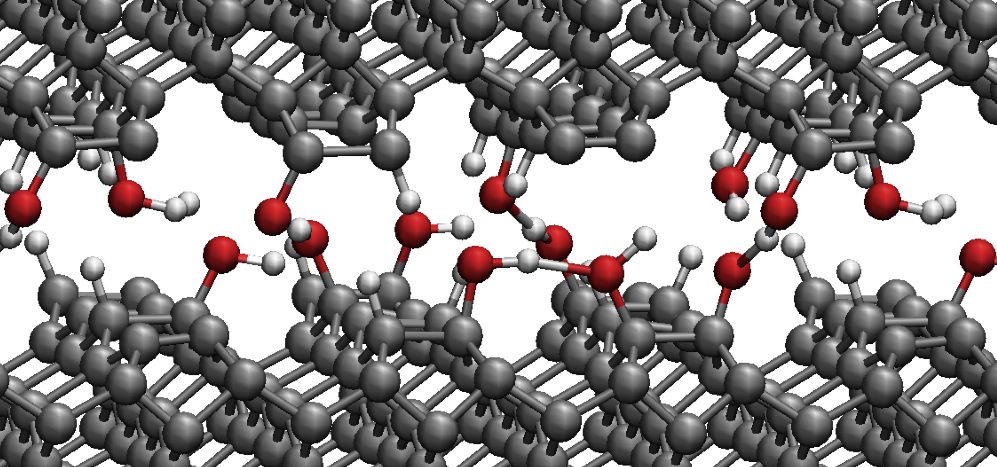

Nanotribology of carbon-based materials

Carbon based materials take a big part in nanotribological studies. Many of those material show exceptional tribological behavior, such as low friction and low wear rates. Examples of these materials include diamond, DLC, graphite, graphene and others. Carbon materials can hybridize easily forming variant bonds which can demonstrate a very high level of tribological performance. Hard carbon materials are considered to produce inert and sharp surfaces which are usually wear resistant David Grierison and Robert Carpick (2007). Superlubricity states were observed for DLC based materials.

References

- Bhushan, B. (2007). Nanotribology, nanomechanics and nanomaterials characterization. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 366(1869), 1351-1381.

- Erdemir, A., & Donnet, C. (2006). Tribology of diamond-like carbon films: recent progress and future prospects. Journal of Physics D: Applied Physics, 39(18), 311.

- Grierson, D. S., & Carpick, R. W. (2007). Nanotribology of carbon-based materials. Nano Today, 2(5), 12-21.

Be the first to comment