Founder of TriboNet, Editor, PhD (Tribology), Tribology Scientist at ASML, The Netherlands. Expertise in lubrication, friction, wear and contact mechanics with emphasis on modeling. Creator of Tribology Simulator.

Evolving friction of graphene

Two-dimensional materials are defined as substances with the thickness less than few nanometers. While there may exist around 500 of various 2D materials, the first discovered 2D material is graphene. Graphene is flexible, transparent, possesses higher conductivity than copper and is stronger than steel – no wonder it has been studied in many research areas including tribology.

In our field, graphene is a promising material to be used as an additive or as a solid lubricant and may improve the efficiency of many mechanical devices. It was shown to be effective as an additive. It was first predicted theoretically and further confirmed experimentally that graphene-gold interface results in a superlubricity – a state of vanishingly low friction. A macro-scale superlubricity was achieved with the aid of graphene and Diamond Like Carbon (DLC).

Frictional behavior of 2D materials can be sometimes peculiar. For example, graphene may exhibit a negative friction-load dependence: decrease of friction with increase of the applied load. Another evidence showed a friction hysteresis of graphene in humid environment. It was also reported that it is possible to control friction behavior of graphene by varying the applied force of the Atomic Force Microscope tip.

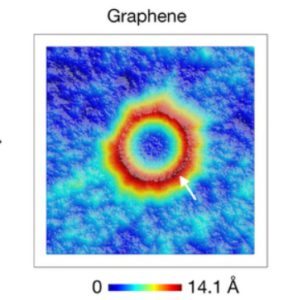

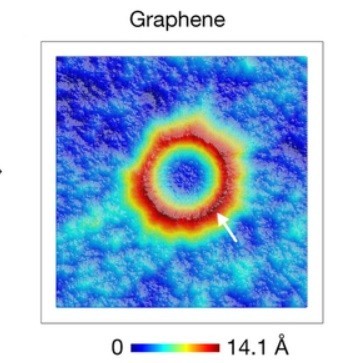

Recently, an international team of researchers from Germany, China and USA addressed another feature in the frictional behavior of graphene: a monolayer graphene (loosely attached to the substrate) exhibits higher friction than multilayer graphene and friction increases with sliding. In the past studies this behavior was attributed to the enhanced capability of puckering of thinner samples. Since puckering leads to an increased contact area the friction is increased. In the current study the puckering and the corresponding friction rise were also observed, however, the change in friction was substantially larger than the change of contact area. Therefore researchers explored further mechanisms of the friction evolution.

Using Molecular Dynamic Simulations and performing the analysis on a monolayer of graphene, the researchers clearly observed two simultaneous effects: enhancement of the pinning of individual carbon atoms (getting an atom into an energetic trap) and also an increase of the number of pinned atoms (commensurability). Both of these effects are attributed to a high freedom of the graphene atoms due to its enhanced bending flexibility. For a multilayer graphene, the flexibility is reduced and the researchers showed that the pinning strength and the overall commensurability are reduced. To confirm this result, the simulations were also performed on a strongly bonded graphene and the friction strengthening were not observed, owing to a much less flexibility.

Presented results can be used to control the friction developed on the surface of graphene.

Further details can be found in the original article: “The evolving quality of frictional contact with graphene”, doi:10.1038/nature20135.

Leave a Reply

You must be logged in to post a comment.

“…[T]he simulations were also performed on a strongly bonded graphene and the friction strengthening were not observed, owing to a much less flexibility.”

Another reason for in situ (bottom-up) synthesis of graphene, rather than attempting to use ex situ (suspended) graphene as a lubricant additive. If the graphene is synthesized on the substrate (surface to be lubricated), it is likely to be more bound to it and less mobile (free). Now, add to the equation the removal of surface asperities by graphene-coated (rigid) polishing spheres, interposed between the interacting (graphene-coated) surfaces, and you have the conditions for superlubricity reported elsewhere (by simulation) using graphene-wrapped nanodiamond on DLC.