Administration of the project

Fatigue Wear

Table of Contents

Fatigue wear

Definition:

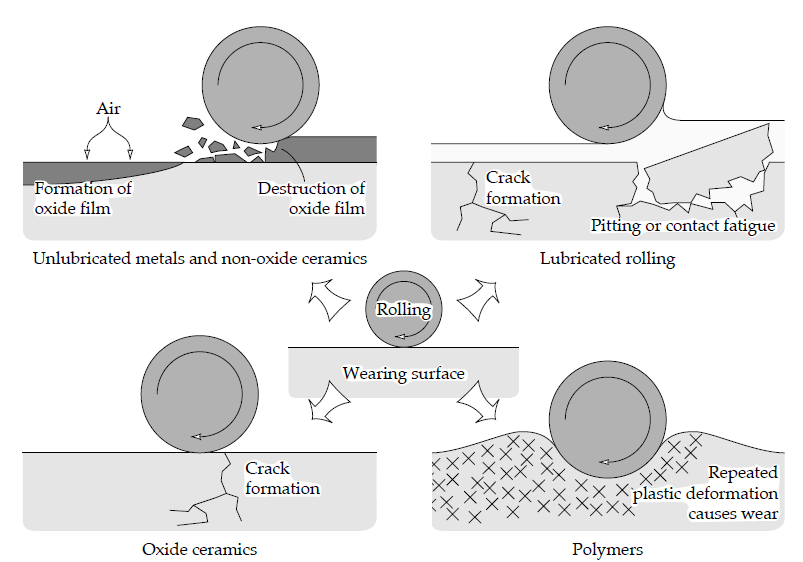

Fatigue wear is a type of wear in which the surface damage of the material takes place due to strain-induced on the surface for a particular number of cycles to a certain critical limit. The fatigue process is generated differently in different conditions, it depends on the type of materials or the type of contact, etc. In case of the metals, the fatigue wear is induced by the creation of surface and subsurface cracks which after a certain number of cycles lead to severe damage. Since this wear is determined by the mechanics of crack formation which is induced by high levels of strains causing the modification of the microstructure of the material’s surface affecting the wear processes [1]. The Fig-1 shows the schematic figure of fatigue wear.

Fig-1 Schematic figure of fatigue wear.

Mechanism of fatigue wear:

The mechanism of the fatigue wear formation starts from the cracks and fissures initiated on the surface of the material, the crack generated on the surface is the result of the strain-induced on the surface due to external conditions like sliding or rolling on the surface [2].

Process of crack initiation and propagation:

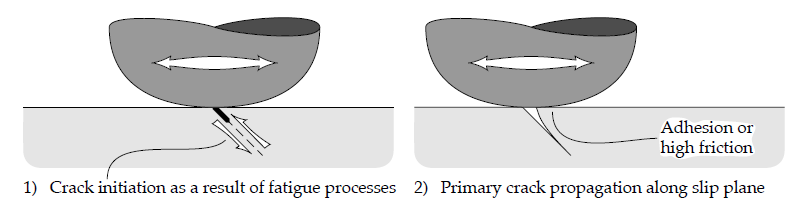

Step-1

The region at which the strain-induced reaches the critical limit is considered the weak point at which the crack initiation process starts. The crack initiated at this weak point propagates along the direction of the weak planes or dislocation cell boundaries leading to the generation of primary crack. This step is shown in Fig- 2.

Fig-2 Schematic figure of fatigue wear primary crack initiation [1].

Step-2

The primary crack on further stresses induced due to the sliding contact at the interface matures into secondary cracks. These secondary cracks formed on the subsurface of the material propagates along the weaker plane towards the surface forming the wear particles on the surface. This step is schematically shown in Fig- 3.

Fig-3 Schematic figure of fatigue wear secondary crack initiation [1].

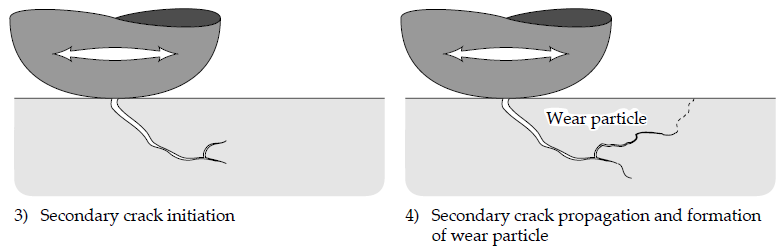

Fatigue wear due to sliding contact:

The fatigue wear in the sliding contacts mainly occurs due to the unlubricated conditions and also due to the sliding motion at the interface of the material reciprocating. The crack initiation takes place at the weaker region on the surface and in this region, there is the orientation of the planes parallel to the sliding motion. The crack mitigates from the surface to the subsurface leading to laminar wear particles along the plane [3]. Lubrication plays an important role in the case of fatigue wear due to sliding contacts because the lubricant reduces the friction at the surface. The effect of lubrication causing the wear can be explained using the delamination model of wear. The reduction in friction due to the lubrication reduces the delamination which further reduces the wear [4]. The fatigue wear due to sliding contact is shown schematically in Fig-4.

Fig-4 Schematic figure of fatigue wear initiation in sliding contact [1].

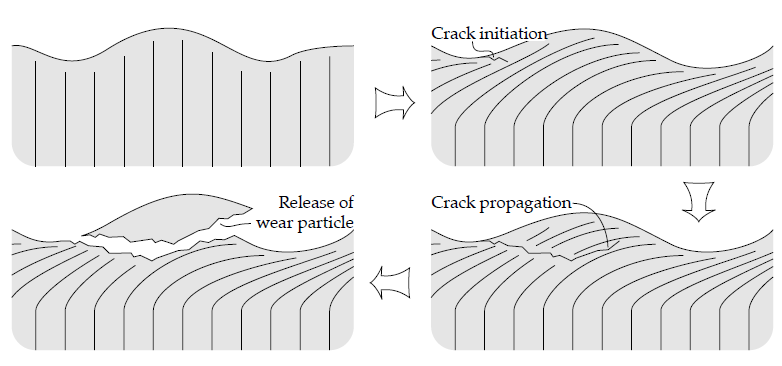

Fatigue wear due to rolling contact:

At the rolling contacts, the materialistic properties of the surface of the material play an important role because of the concentration of the large stresses due to rolling. The stresses are repetitive in nature leading to severe damage on the surface. The fatigue wear depends on the conditions of rolling in different materials which can be explained as. In Fig-5 we can see the schematic representation of the fatigue wear mechanism in rolling contact for different materials.

For metals and non-oxide ceramics without lubrication:

For metals in unlubricated conditions, the rolling on the surface causes the continuous regeneration of the oxide films on the surface. The cycle of formation and destruction of the protective oxide films on the material surface is the characteristic of the wear in these materials.

For oxidising ceramics:

In the case of the ceramics which form the string oxidising films, the wear formation can be controlled to a larger extent. The oxide films act as durable lubricating films reducing wear.

For metals with lubrication:

In lubricated conditions, the surface of the materials will have the protective film of the lubricant against wear. This film helps in avoiding the solid-solid contact, however, due to the large cyclic stresses on the surface, there is the formation of the weaker points on the surface which leads to crack generation causing the fretting wear.

For polymers:

In the case of the polymers when they are in rolling contact with any hard metals there is a concentration of the cyclic load generation on the surface. This leads to deformation of the polymer surface and there is only rapid wear during the geometric changes at the surface after a point the wear becomes milder due to the reduction of contact stresses.

Fig-5 Schematic figure of fatigue wear mechanism in rolling contact for different materials [1].

Contact fatigue:

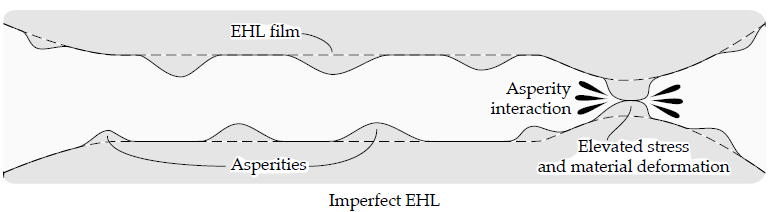

The cause of the contact stresses on the surface of the materials is the result in lack of materials properties, improper lubrication, and operating conditions. The surface finish on the materials plays an important role in contact fatigue generation, also the proper lubrication on the surface protects it from contact fatigue. In the lubrication, the elastohydrodynamic (EHL) lubrication is the most important regime in which the contact fatigue generation is seen, during the rolling if there is any wear debris that gets trapped on the lubricant film might create contact fatigue on the surface.

In the case of the surface finish of the materials, the elevated asperities on the surface during the EHL regimes will have contact with its counter surface and causes the elevation in the stresses at the surface. This leads to the imperfect EHL film on the surface causing fatigue wear [5]. In Fig- 6. a schematic diagram of imperfect EHL film causing the contact fatigue is shown.

Fig-6 Schematic diagram of imperfect EHL film causing contact fatigue [1].

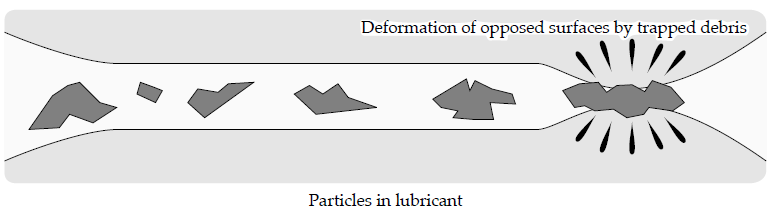

Similarly, during the wear, if there is wear debris formation, this wear debris gets entrapped in the lubricant film. This entrapped debris if comes in contact with the elevated asperities on the surfaces and gets trapped there generating the stresses causing the fatigue wear [6]. This mechanism is shown in Fig- 7.

Fig-7 Schematic diagram wear particles causing the contact fatigue [1].

Fatigue wear research:

The design aspects of any mechanical components play an important role in reducing wear, it is required to investigate the design aspects and modify the traditional designs to prevent wear and increase its life and efficiency. K Mao conducted similar work in his study on analyzing the gear tooth contact to reduce fatigue wear. He found the solution based on modifying the micro geometry of the gear tooth i.e. tip relief, face width crowning, etc to reduce the fatigue wear [7]. B. Zhang et.al. studied the simulation of the fatigue wear coupling mechanism of the aviation gear and found that the initial crack generation in the fatigue wear at the surface and the subsurface depends on the surface roughness of the material [8].

References:

[1] Stachowiak, G.W. and Batchelor, A.W., 2013. Engineering tribology. Butterworth-heinemann.

[2] D.A. Rigney and J.P. Hirth, Plastic Deformation and Sliding Friction of Metals, Wear, Vol. 53, 1979, pp. 345-370.

[3] N. Soda, Y. Kimura and A. Tanaka, Wear of Some F.C.C. Metals During Unlubricated Sliding Part I: Effects of Load, Velocity and Atmospheric Pressure, Wear, Vol. 33, 1975, pp. 1-16.

[4] N. Soda, Y. Kimura and A. Tanaka, Wear of Some F.C.C. Metals During Unlubricated Sliding Part II: Effects of Normal Load, Sliding Velocity and Atmospheric Pressure on Wear Fragments, Wear, Vol. 35, 1975, pp. 331- 343.

[5] R.S. Sayles and P.B. MacPherson, The Influence of Wear Debris on Rolling Contact Fatigue, Proc. Symposium on Rolling Contact Fatigue Testing of Bearing Steels sponsored by ASTM Committee A-1 on Steel, Stainless Steel, and Related Alloys, Phoenix, 12-14 May 1981, editor: J.J.C. Hoo, 1981, pp. 255-274.

[6] S.H. Loewenthal and D.W. Moyer, Filtration Effects on Ball Bearing Life and Condition in a Contaminated Lubricant, Transactions ASME, Journal of Lubrication Technology, Vol. 101, 1979, pp. 171-179.

[7] Mao, K., 2007. Gear tooth contact analysis and its application in the reduction of fatigue wear. Wear, 262(11-12), pp.1281-1288.

[8] Zhang, B., Liu, H., Zhu, C. and Ge, Y., 2021. Simulation of the fatigue-wear coupling mechanism of an aviation gear. Friction, 9(6), pp.1616-1634.

Leave a Reply

You must be logged in to post a comment.

Hi

Is it possible to detect shaft fatigue through oil analysis? We had a Cooling Tower gearbox shaft fail on what looks like fatigue. There was also indication of accelerating wear 3 months before the failure. Could the fatigue cracks on shaft be generating the wear?