Administration of the project

Stribeck Curve

Table of Contents

What is Stribeck Curve?

Stribeck curve is a fundamental and one of the most widely known concepts in tribology and lubrication fields. The concept represents the friction behavior in lubricated contacts as a function of viscosity of the lubricant, entrainment speed and roughness (sometimes, just roughness). Richard Stribeck along with Mayo Hersey are accredited as the pioneer researchers of the 20th century, who introduced Stribeck curve by extending their work on the topic of friction within the railway industry; however the results of the research were in coherence with the previous researches.

Origin of the concept

Various machines and machine elements make use of lubrication to reduce friction and wear. The degree of such reduction hugely depends on the so called lubrication regime established in the contact of rotating elements. In 1902 Richard Stribeck studied the friction in hydrodynamic bearings and reported existence of a minimum of friction coefficient as function of operating conditions [1,2]. Later, based on the results of Stribeck, Gumbel found that the curves of friction lay on a uniform curve if plot as a function of a parameter that includes viscosity ![]() , speed

, speed ![]() and load

and load ![]() (or pressure). With further research and invention of surface roughness measurement techniques it was recognized that the friction coefficient can be also plotted against ratio of the lubricant film thickness (usually central film thickness) to combined root mean square of the surface roughness of the contacting surfaces,

(or pressure). With further research and invention of surface roughness measurement techniques it was recognized that the friction coefficient can be also plotted against ratio of the lubricant film thickness (usually central film thickness) to combined root mean square of the surface roughness of the contacting surfaces, ![]() ,

, ![]() . Also, one could obtain a Stribeck curve by plotting the friction coefficient as a function of speed

. Also, one could obtain a Stribeck curve by plotting the friction coefficient as a function of speed ![]() , if other parameters are fixed.

, if other parameters are fixed.

Explanation of the Stribeck curve shape

With the development of Elastohydrodynamic theory and surface roughness measurement tools, the behavior of the Stribeck curve was well explained. If one starts with inadequate lubrication or extremely harsh conditions, where the parameter ![]() is very small, the friction developed in the contact is determined by the contact between the solids (or respective boundary lubricant films). The whole load is carried by the solid to solid contacts. The friction developed in the solid to solid contact is generally quite high as compared to the friction developed by the viscous shear of the lubricant layers. This type of lubrication is referred to as Boundary Lubrication (BL) regime (see the figure above) and the friction coefficient is typically in the range of

is very small, the friction developed in the contact is determined by the contact between the solids (or respective boundary lubricant films). The whole load is carried by the solid to solid contacts. The friction developed in the solid to solid contact is generally quite high as compared to the friction developed by the viscous shear of the lubricant layers. This type of lubrication is referred to as Boundary Lubrication (BL) regime (see the figure above) and the friction coefficient is typically in the range of ![]() .

.

If the lubrication conditions get better or the operating conditions become less harsh, the lubricant film thickness becomes thicker. The lubricant film thickness starts to separate the surfaces, part of the load is carried by the lubricant and only some parts of the solids come to the direct contact. In this case, the total friction is a combination of the solid to solid contact friction and the friction of the lubricant layers. Friction of the lubricant layers is typically less that the friction of solid to solid contacts, thus overall the friction decreases. This case corresponds to Mixed Lubrication regime (ML). One could describe the friction coefficient ![]() in mixed lubrication as follows:

in mixed lubrication as follows:

(1) ![]()

where ![]() is the friction coefficient in boundary lubrication regime,

is the friction coefficient in boundary lubrication regime, ![]() is the hydrodynamic friction and

is the hydrodynamic friction and ![]() is the ratio of the load carried by the solid to solid contact to the load carried by the lubricant. From this relation its clear that with the increase of the solid to solid contact, friction drops, since up to a certain point

is the ratio of the load carried by the solid to solid contact to the load carried by the lubricant. From this relation its clear that with the increase of the solid to solid contact, friction drops, since up to a certain point ![]() .

.

With further improvement of the operating conditions, the film thickness gets larger and at a certain point, there will be no direct solid to solid contact and full film lubrication conditions are encountered. Here friction is developed by viscous shear of the lubricant layers. As can be seen from the figure above, friction stops decreasing and starts to increase in the full film lubrication regime, despite the fact that the solid to solid contact disappears. This behavior is attributed to the increase in hydrodynamic friction. The issue is that in order to increase the film thickness, one needs to either increase viscosity or speed or decrease load. All lead to increase in shear stresses (except for decrease in load, but there friction force drops slower than the normal load) and as a consequence of friction coefficient.

Quick Video Explanation

Lambda Ratio

Lambda ratio is a very well known parameter in the field of lubrication and tribology that is used to distinguish the lubrication regimes. Lambda ratio is defined as the ratio of the (central) EHL film thickness to the combined root mean square of the surface roughness:

(2)

Here ![]() is the standard deviation of the surface heights of the

is the standard deviation of the surface heights of the ![]() -th surface in contact.

-th surface in contact.

Calculate Central Film Thickness Online: EHL Film Thickness Calculator – Elliptical (Point) Contact

Typically, the lubrication regimes are identified based on ![]() as follows :

as follows :

1) ![]() , full film lubrication regime (FF);

, full film lubrication regime (FF);

2) ![]() , mixed lubrication regime (ML); friction is influenced by both the lubricant properties and those of the “solid” contacts. The total load is partly carried by the lubricant and partly by the solid contacts.

, mixed lubrication regime (ML); friction is influenced by both the lubricant properties and those of the “solid” contacts. The total load is partly carried by the lubricant and partly by the solid contacts.

3) ![]() , boundary lubrication regime (BL); friction is fully determined by the shear strength of the surface boundary layers and is typically characterized by a boundary friction coefficient (relatively constant, characteristic value of a given system).

, boundary lubrication regime (BL); friction is fully determined by the shear strength of the surface boundary layers and is typically characterized by a boundary friction coefficient (relatively constant, characteristic value of a given system).

It should be emphasized that the range of the lambda ratio given above is a rule of thumb and in real cases it may be quite different. Sometimes full film lubrication can be established at lambda values as low as ![]() .

.

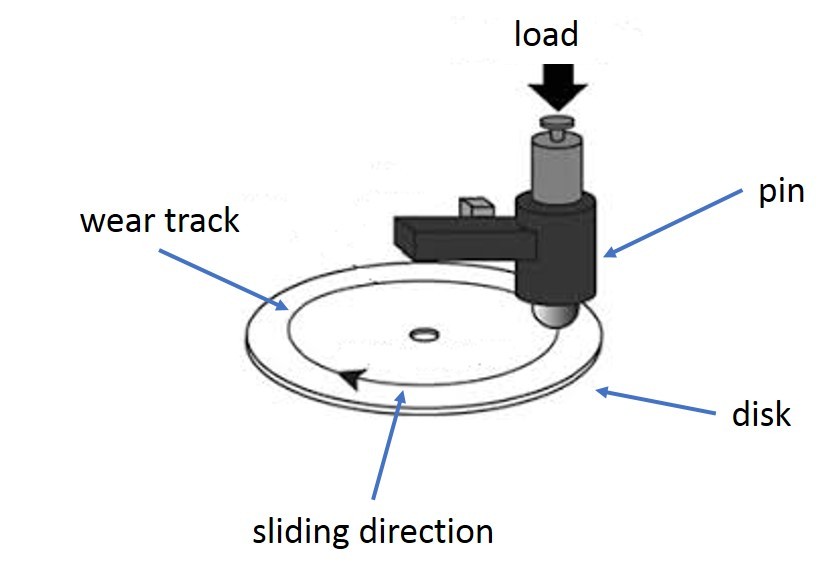

Measuring Stribeck Curve

Measuring Stribeck curve can be useful to evaluate the performance of a certain lubricant or surface finishing of solids in contact. The easiest way to measure Stribeck curve is to use a pin-on-disk machine. Schematically, the pin on disk test is depicted in the figure below. The stationary pin is pressed against rotating disk under the given load. The pin can be of any shape, however, the most popular shapes are spherical (ball or lens) or cylindrical due to ease of alignment of such pins (flat pins are typically subject to certain misalignment which can lead to non-uniform loading and difficulties for theoretical analysis). During the test, the friction force, wear and temperature could be monitored.

The easiest way to measure Stribeck curve is to measure friction coefficient in a tribosystem as a function of speed. This parameter is the easiest to change, since there is no need to change the samples (as in case if you would like to alter friction via surface roughness) or lubricant (in case if you would like to change viscosity). The measurement typically starts from the low speed in order to reach BL regime. Its better to start from this regime in order to minimize the impact of wear on the friction variation during the measurement in the ML and FF. Further, in order to record the Stribeck curve, the speed in the experiments is increased. Increase in speed results in increase of the central film thickness and the lubrication condition goes towards ML and further to full film. This experiment should run relatively fast in order to minimize the impact of the running in. Alternatively one could first run-in the surfaces and then measure the Stribeck curve. Nowadays, changing speed can be done automatically, which makes the test easy and fast. Example of a Stribeck curve:

Of course, one could also build the Stribeck curve as a function of viscosity or surface roughness, but this is much more time consuming.

It is necessary to mention that the tests in tribology should be prepared well. This is due to the fact that the friction is extremely sensitive to the to the surface conditions and lubrication. The surfaces should be finished and cleaned in the same way before starting the experiments.

Impact of running-in on Stribeck curve

During the operation of machine elements, the initial surfaces of the contacting bodies usually start to wear. This wear process typically has a relatively high wear rate in the beginning, followed by a lower wear rate, in the so called steady state wear. The initial process of a high wear rate is called running-in. The running-in stage is the initial phase, characterized by significant wear loss, variation of the friction coefficient and surface roughness evolution. At this stage, the contacting substrate materials are worn due to local plastic deformation.

During the running-in, surface roughness is getting worn and thus, ![]() parameter increases. This means that the Stribeck curve shifts, as shown in the figure below. Interestingly, sometimes also the boundary friction coefficient drops, even though that happens not always.

parameter increases. This means that the Stribeck curve shifts, as shown in the figure below. Interestingly, sometimes also the boundary friction coefficient drops, even though that happens not always.

Calculating Stribeck Curve

Currently, there are two ways available for calculating friction (Stribeck curve prediction) in all lubrication regimes. One could solve numerically the full system of the EHL equations for rough surfaces. In this case, the governing flow equations (e.g., Reynolds equation) and surface deformation equations are solved numerically by taking the surface roughness’s directly into all of the equations. But his approach is computationally intense and consequently has limitations on the size of the computational mesh. On the other hand load-sharing concept can be used to solve the problem approximately, but considerably faster and simpler. The concept, first introduced by Johnson [4], offers advantages of robustness, significantly reduced computational requirements and a relative simplicity. In these models the general problem is split up into two problems: lubrication problem assuming smooth surfaces and a “dry” rough contact problem, for details see [5]. In this case the flow equations are solved assuming that the surfaces in contact are smooth, while the “dry” contact problem assumes that there is no lubricant between the surfaces. These problems are linked via the load carried by the lubricant and by the “dry” contact [6], see figure below.

In the simplest form, the load-sharing concept can use a central film thickness fit to calculate the lubricant film thickness for the lubrication problem and Greenwood-Williamson model (GW) for the “dry” contact problem. This approach can give a good qualitative prediction of the friction evolution, however, it is likely to overestimate friction due to assumptions used in both GW model (assumption of the independent asperity deformation, which overestimates the load carried by asperities) and central film thickness calculations (assumption of a constant film thickness in the contact area, which is true only for “highly” loaded cases), see [6]. In the case of a highly loaded contact, a much better approach would be to use instead of GW models for the solution of a dry contact problem, the half-space approximation approach. In this model, the elasticity equations are solved semi-analytically, which may give a much better prediction of friction, see the figure below. You can use the online tools cited below to calculate Stribeck curve using load-sharing concept.

Online Stribeck Curve Calculator – Elliptical (Point) Contact

Online Stribeck Curve Calculator – Cylindrical (Line) Contact

References

- [1] Stribeck, R. (1901), Kugellager für beliebige Belastungen (Ball Bearings for any Stress), Zeitschrift des Vereins Deutscher Ingenieure 45 (STRIBECK PAPER.pdf).

- [2] Stribeck, R. (1902), Die wesentlichen Eigenschaften der Gleit- und Rollenlager (Characteristics of Plain and Roller Bearings), Zeit. des VDI 46.

- [3] Aydar Akchurin, Rob Bosman, Piet M. Lugt, Generation of wear particles and running-in in mixed lubricated sliding contacts, Tribology International, Volume 110, 2017, Pages 201-208, ISSN 0301-679X, https://doi.org/10.1016/j.triboint.2017.02.019.

- [4] Johnson KL, Greenwood JA, Poon SY. A Simple Theory of Asperity Contact in Elasto-Hydrodynamic Lubrication. Wear. 1972;19:91-108.

- [5] Zhu D, Hu Y-Z. A computer program package for the prediction of EHL and mixed lubrication characteristics, friction, subsurface stresses and flash temperatures based on measured 3-D surface roughness. Tribology Transactions. 2008;44:383-90.

- [6] Akchurin, A., Bosman, R., Lugt, P.M. et al. On a Model for the Prediction of the Friction Coefficient in Mixed Lubrication Based on a Load-Sharing Concept with Measured Surface Roughness. Tribol Lett 59, 19 (2015). https://doi.org/10.1007/s11249-015-0536-z

- [7] Li, X., Wang, A. & Lee, KR. Mechanism of contact pressure-induced friction at the amorphous carbon/alpha olefin interface. npj Comput Mater 4, 53 (2018). https://doi.org/10.1038/s41524-018-0111-x

- [8] Bruker https://www.bruker.com/

Leave a Reply

You must be logged in to post a comment.

I think the name is Ludwig Gumbel and not “Gumberl”.

In the text several references are made but these references are not reported in this article.

The first paragraph in this article says: ” ….a function of viscosity of the lubricant, entertainment speed and roughness”. So, what the hell is “entertainment speed”???

That is entrainment speed, but with a bit of fun 🙂 thank you for the comment, fixed it 🙂