The article is written by Riya Veluri, an editorial team member of Industrial Lubricants. After her graduation, Riya works as a website developer & SEO specialist in Lubrication & Tribology Industry & writes technical articles on Lubricants, Lubrication, Reliability & sustainability.

Cavitation

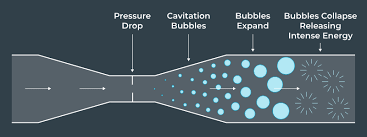

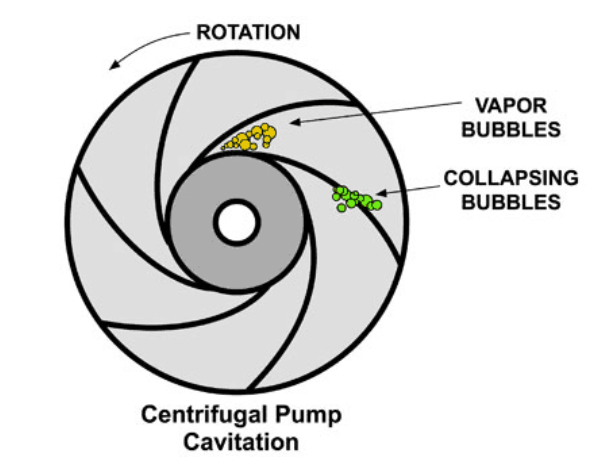

Cavitation is a phenomenon that occurs when a liquid is subjected to a pressure drop that causes its pressure to fall below its vapour pressure. This forms vapour bubbles within the fluid, collapsing as the pressure increases again.

Cavitation is commonly observed in pumps, propellers, and other fluid dynamic systems. Unfortunately, it can cause significant damage to these systems and reduce their efficiency. For example, the collapse of vapour bubbles in a pump can create intense shockwaves that can erode the metal surfaces of the pump, leading to reduced performance and increased maintenance costs.

Several factors, including high fluid velocities, fluid pressure drops, and low liquid levels, can trigger the formation of cavitation bubbles. In addition, the severity of cavitation damage is also influenced by factors such as the size and number of bubbles, the duration of the bubble collapse, and the properties of the liquid.

Figure 1. Cavitation: easily explained!

How engineers prevent/lower cavitation effects?

- Increasing the inlet pressure of the fluid to the pump or propeller.

- Reducing the fluid velocity by using larger diameter impellers or diffusers.

- Using cavitation plates or other devices to create a positive pressure at the inlet of the pump or propeller.

- Using coatings or other surface treatments to increase the resistance of the metal surfaces to erosion caused by cavitation.

Additionally, numerical simulation tools such as Computational Fluid Dynamics (CFD) can be used to predict and analyse the potential for cavitation in a given system, allowing engineers to design systems that are less susceptible to cavitation damage.

Cavitation can also occur in other applications, such as in pipelines, water treatment systems, and even in the human body where it can be responsible for blood vessel damage and other medical issues.

Figure 2. Centrifugal pump cavitation, https://www.thermal-engineering.org/what-is-suction-cavitation-definition/.

Negative Effects of Cavitation

- Cavitation is a complex phenomenon that can significantly adversely affect fluid dynamic systems, including pumps and propellers. However, by understanding the factors that contribute to cavitation and utilizing various prevention methods, engineers can design systems that are more resistant to cavitation damage, thus increasing efficiency and reducing maintenance costs.

- Another essential aspect of cavitation is the noise that it generates. The collapse of the vapour bubbles creates intense pressure waves that can be heard as a loud, high-pitched noise. This noise can be a nuisance in some applications, such as in water treatment plants or in boats and ships, and can also be a safety hazard in industrial settings where it can be difficult to hear warning signals or alarms.

- Cavitation can also lead to vibration, further damaging the system or the surrounding structure. Some systems that are affected by cavitation include water and sewage systems, oil and gas pipelines, and hydroelectric power plants.

- Another essential aspect of cavitation is the impact it can have on the efficiency of the system. The formation of vapour bubbles in a pump or propeller reduces the effective flow area, which decreases performance. Additionally, the collapse of the vapour bubbles causes turbulence and generates heat, which can further reduce efficiency.

- In pumps, cavitation can lead to reduced head and flow, and in propellers, it can lead to reduced thrust and increased fuel consumption. Both cases can result in increased operating costs and reduced productivity.

- Cavitation can also occur in valves, leading to leakage and reduced control. In some valves, cavitation can cause erosion and pitting, further affecting the flow control and causing leakage.

To prevent or mitigate cavitation, engineers may use a variety of methods. One standard practice is to design the system with a larger inlet area, which reduces the pressure drop and the potential for cavitation. Another approach is to use a more viscous fluid, which reduces the fluid velocity and the potential for cavitation.

Figure 3. Cavitation damage on a propeller. https://commons.wikimedia.org/wiki/File:Cavitation_Propeller_Damage.JPG

Positive Aspects of Cavitation

It’s also worth mentioning that cavitation can be used in specific applications as a beneficial process. Some of the most notable positive aspects of cavitation are:

- Cleaning: Ultrasonic cavitation is used in cleaning applications where high-frequency sound waves are used to create bubbles that implode and remove dirt and debris from surfaces. This method is beneficial for cleaning hard-to-reach areas and removing stubborn stains and contaminants.

- Mixing and Emulsifying: Cavitation can be used to mix and emulsify liquids, which can be helpful in the food and pharmaceutical industries. The collapse of the bubbles generates high shear and turbulent mixing, which can be used to create homogenous mixtures and emulsions.

- Medical Applications: Focused ultrasound cavitation can destroy certain tumours or kidney stones. The bubbles created by the ultrasound waves generate intense pressure and heat, which can be used to ablate the tissue.

- Mass Transfer: The intense mixing and shear forces generated by cavitation can enhance mass transfer in chemical reactions, such as oxidation and reduction reactions. This can be useful in various industrial applications, such as wastewater treatment and catalytic reactions.

- Surface Treatment: Cavitation can also be used to treat surfaces, such as polishing, surface activation and surface cleaning. The intense forces generated by the collapse of bubbles can remove surface impurities, smooth rough surfaces, and activate surfaces for better adhesion.

Figure 4. Cavitation resulting from a pressure drop, https://www.iqsdirectory.com/articles/mixer/homogenizer.html.

It’s worth mention that the positive aspects of cavitation are highly dependent on the specific application and the design of the system. Therefore, it’s crucial to have a proper understanding of the fluid dynamics, the properties of the liquid, and the system design to take advantage of the positive aspects of cavitation. Also, cavitation can be caused by external factors such as temperature changes, fluid composition changes, and the surrounding environment. Therefore, it’s essential to consider such elements in the system’s design, operation and maintenance.

In summary, cavitation is a complex phenomenon that can have both negative and positive effects depending on the application and can significantly impact the efficiency and performance of fluid systems. Therefore, engineers and designers need to understand the factors that contribute to cavitation and employ appropriate prevention methods to minimize damage and noise while also taking advantage of the benefits of cavitation in specific applications.

Leave a Reply

You must be logged in to post a comment.

Nice presentation, certainly of a great help.

Thank you

I appreciate how you’ve explained the science behind cavitation in a clear and accessible way. The visuals and diagrams you’ve included make it even easier to grasp the concept. It’s fascinating to learn about the different types of cavitation and their practical implications in various fields.

Moreover, the historical context and real-world examples you provided added depth to the topic. It’s incredible to see how cavitation has been observed and harnessed throughout history, from the damaging effects in propellers to its use in medical applications.