Administration of the project

Estimation of functional properties of coatings by different tribological test methods

By Dr. Ameneh Schneider – Optimol Instruments GmbH and Dr. Mathias Woydt – MATRILUB

Introduction

Interest in special coatings and thin films for tribological applications increased rapidly in the last few decades, especially driven by the automotive industry [1,2]. Specific properties of coatings which are interesting for many engineering applications are:

- Low coefficients of friction

- Wear protection

- High to higher hardnesses

- Improved corrosion resistance

- High thermal conductivity

In general, tailoring the surface properties and microstructure of films is very important for any application. Adequate adhesion between coating and substrate is very crucial for tribological longevity. A multitude of process parameters affect the hardness, thickness, residual stresses, roughness, adhesion, elasticity, etc., which in parallel shall not alter the tribological performances of coatings and layers. Thin film coatings for friction reduction make only sense, when they display wear rates below <<10-7 mm³/Nm under lubricated conditions, also because they are thin, and will not delaminate or fragment over time. Due to the high hardness of most coatings and thin films, a smooth surface topography is essential for low wear of the tribosystems and the counter body. Plateau-like profiles have favorable tribological advantages. The major reasons are:

- Smaller peak contact pressures in solid body contact

- Less material fatigues

- Reduction of running-in effects (wear-intensive in process adaptation of the surface structure)

- Reduced so-called cold wear

- Reduced abrasive action against counter body

- Lower risk of furrow

- Furthermore, between the plateaus there are depots for lubricant and for wear particles!

Today, hard thin films and coatings are characterized by scratching with a spherical tipped diamond stylus. During this test, either a constant or increasing force is applied to the pin sliding perpendicular to the surface to be tested to promote adhesion and/or cohesion failure of the layer/substrate interphase. Scratch testing indicates also as a simple and rapid method the level of toughness. The onset load for coating cracking is a measure of the cohesion strength of the coating.

For tribologically stressed material couples, the following characteristic values are usually required: friction and wear behavior; Resistance to scuff or adhesion under gradually increasing load; Fretting wear resistance at low loads and high oscillating frequencies; Wear resistance under unidirectional sliding. Selected examples of different test modes are in the following displayed to establish a functional profile of thin film coatings.

By choosing the pieces/specimens with a metallurgy corresponding to real contact geometries of application regarded under controlled tests conditions by SRV® (e.g. controlled humidity, bulk temperature, dynamic load, frequency and stroke, etc.) model tests can be executed with a high degree of transferability to practical applications [3]. Keys are here the tribometric operating conditions, which shall match those of the application [4]. Additional available measurement sensors, like electrical contact resistance, acoustic emission or total linear wear unveil further insights into the origins of the observed wear mechanisms. SRV® is seen globally as a precise tool for benchmarking the tribological profile of different layers and thin films, e.g. diamond-like carbon (DLC).

Example 1: Evaluation of anti-adhesion characteristics of diamond-like carbon film using reciprocating ball-on-plate tribometer (SRV®)

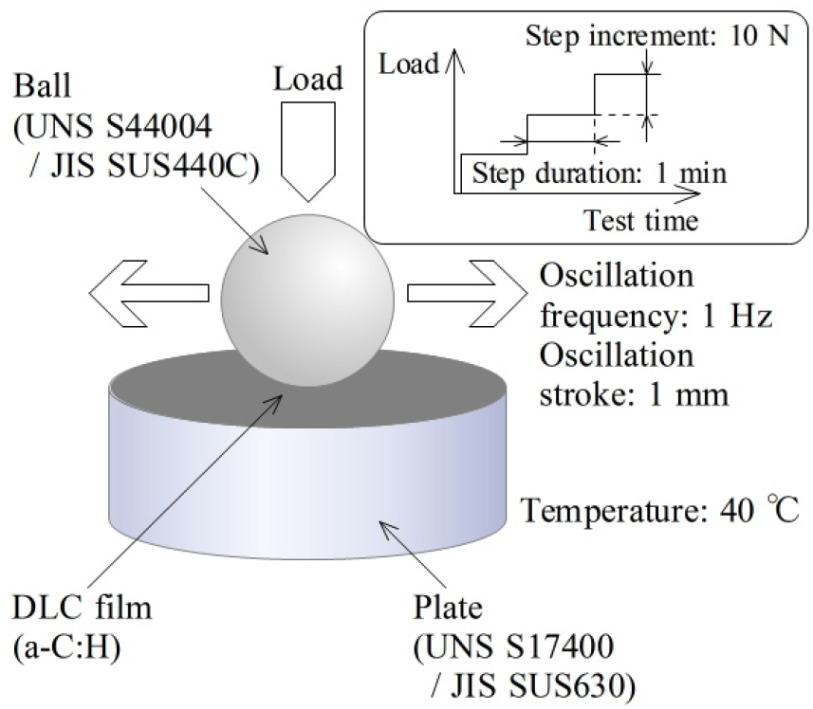

Delamination characteristics of diamond-like carbon (DLC) thin films can be investigated by a reciprocating load step test. The load step increment is 10 N every minute. In such a test, the load carrying capacity leading to a malfunction of DLC films due to delamination and/or wear can be assessed. The test geometry, test conditions, materials and tribological test conditions are shown in Figure 2. Flat disks in X5CrNiCuNb16-4 (AISI 630) were coated with different DLC films (a-C:H, a-C and ta-C) with thicknesses of 0.1, 0.8 and 1.0 mm. The chosen ball materials were X110Cr16 (AISI 440C) or Al2O3. Alumina has the advantage of the absence of tribo-oxidation under such test conditions.

This load step tests indicates the load carrying capacity, the evolution of coefficient of friction as function of load and wear. The test is terminated, when the highest load was reached, delamination at a given load occurred or excessive wear is indicated by fluctuations in the signals of coefficient of friction and oscillation stroke. The adhesion of films was estimated by observation of worn surface and two wear mechanism are discussed by Mano et al. [5], which can be summarized as follows:

- COF is increased when DLC delaminates by fatigue of the interphase between coating and substrate and/or

- COF increase due to embedment of wear debris

Example 2: Evaluation of friction and wear of carbon-based thin films

The tribological properties of most coatings and thin films are sensitive to relative humidity [6] and increasing temperature. In internal combustion engines, the surface temperatures of cams reach 170°C and of piston ring up to 300°C. In consequence, the interaction of lubricants and their additives with thin films as function of temperature in relation to friction, wear and fatigue is of importance.

Frictional and wear behaviors of alumina and silicon nitride balls oscillating against an industrial a-C:H thin film deposited Cronidur30 disk (see Fig. 3) and lubed by a high-temperature ester oil were investigated at temperatures up to 250°C [7]. Independent from the ball material, the wear of the a-C:H film increases with increasing oil temperature, whereas the total wear of the tribosystems depend also from the type of ceramic used.

Molybdenum dithiocarbamate is a very effective friction modifier. The functional interaction between ta-C and a-C:H thin films deposited on 100Cr6 (AISI 52100; SUJ2) disks oscillating against roller in 100Cr6 in API Group III base oil additivated with MoDTC is represented in Figure 3. The SRV® tests confirmed the friction reducing effect of MoDTC but illuminate increased wear of a-C:H thin film by MoDTC [8].

Figure 3: Evolution of coefficients of friction (left) at 80°C and specific wear rates (right) of ta-C and a-C:H thin films [[8]]

Example 3: Enhanced tribological performances of nano-crystalline diamond (NCD) film

The target of this study [9] was to understand the tribological response of NCD-films in the presence of high-quality lubrication and exploring the possibility of using them in future automotive system.

Test parameters in this study were as follow:

- Different geometries and material of acting body

- Different loads adjusting the specific contact pressure

- 3 different lubricant qualities

- Temperature: RT

- Frequency: 10 Hz

Figure 4 illustrates the effect of type of ball material (counter body).

The main results of this study can be summarized as follow:

- The material of counter body plays a significant role

- The existing roughness points (asperities) Rp/Rz > 0.7 favorite layer damage at high pressures in the SRV® Tests

- The lubricant quality in combination with coated layer plays in most cases a subordinate role (exception: glycerol mono-oleate (GMO), Molybdenum-containing lubricants)

- The humidity affects the CoF values, especially for all DLCs.

Example 4: A screening test method for anti-wear coatings (DLC) with SRV®

5 different carbon-based coatings of different types were deposited on standard SRV® disk (100Cr6) by 3 suppliers. The important data of selected disks for this study are summarized in Table 1.

Table 1: Data of selected DLC coated disks

The chosen operating conditions based on the results of pretests and experiences from literature and recommendations from the suppliers are as follows:

- Duration: 30 min.

- Load: 5 N

- Frequency: 1 Hz

- Stroke: 5 mm

Ball bearing steel 100Cr6 (AISI 52100) and alumina (Al2O3) were chosen for upper specimen (ball with 6 mm diameter) materials. It is well known that the environmental conditions have a significant effect of the tribological results. Two different relative humidity (r.h.) values were adjusted and controlled by the climate tool connected to the SRV®5 test chamber. Environmental test conditions were as follows:

- Temperature: 25 °C

- No Lubricant (dry)

- Relative humidity in the testing camber:

- 30 % RH

- 90 % RH

Figure 5 shows exemplary the comparison of evolution of coefficients of friction (CoF) values with test time. The effect of the ball material can be observed clearly. Alumina is at RT insensitive to tribo-oxidation, whereas 100Cr6 forms by tribo-oxidation iron oxides, which hydrolysis with humidity to -, – und -FeOOH and Fe(OH)2.

SRV® Software offers different automatically evaluation of the results. Evaluation of average value of CoF for chosen periods is easily possible. The coefficients of friction can be displayed at any desired test time, e.g. here in Figure 6 at 5 and 25 minute.

The comparison of evaluated CoF for all conditions are shown in Figure 7. The effect of ball material and the level of humidity can be observed clearly. With ceramic ball, the CoF values are significantly lower except for coating #2.

Conclusions:

- A full functional profile of coatings and thin films can be established via tribometric techniques.

- Tribological performances of different surface coatings can be benchmarked with SRV® and 2disk tribometers.

- Adhesion performance and load carrying properties of hard thin films by means of oscillating load step test, which delivers also data on coefficients of friction as function of Hertzian contact stresses.

- Friction, wear rates and load carrying capacity under slip-rolling and high Hertzian contact pressures illuminate the retention of friction and slip-rolling resistance.

- An accelerated friction and wear screening test of tribosystems is presented as well.

- Anti-fretting resistance (according to ASTM D7495).

Remark: Two additional sensors for SRV®5 machines deliver further valuable information on the wear mechanisms of coatings and their origins:

- Electrical resistance – measures changes in electrically contact resistance due to coatings delamination, coatings worn down to the substrate, tribochemisty, etc. and

- Acoustic noise emission detects the early beginning of delamination and fatigue before it is seen macroscopically.

Using ETS (Easy Tribology Screener) for coatings

This newly developed tabletop tribometer enables coating producers to benchmark the tribological performances of their product in a very simple manner. With sinusoidal movement under normal load up to maximum 300 N equipped with an innovative online wear sensor, this machine can help coating producer to develop their quality and even their production process. One DLC coating is measured under following parameters:

- Load: 10 N

- Frequency: 10 Hz

- Stroke: 2 mm

- Temperature: RT

- Rel. humidity: 35 %

- Lubrication dry

- Duration: 20 min

Figure 8 displays a good repeatability for the online recorded evolution of coefficients of friction and linear, total wear of both tribo-elements.

2disk test rig for determining the tribological profile of coatings under slip-rolling

2disk represents a new screening method to differentiate the frictional response, wear behavior and slip-rolling resistance in one test under of slip-rolling, high Hertzian contact pressures and different lubrication regimes [10]:

- unlubricated conditions,

- mixed / boundary friction conditions and

- hydrodynamic lubrication.

This functional profile is complementary to bench tests and 2disk shortens the screening of oils, additives, materials and coatings and the development time of products.

Figure 8 shows the results of investigation on different thin film coatings under slip-rolling with 10% of slip and very high Hertzian contact pressures (P0max 1.5-1.95 GPa). Some coating materials with low coefficients of friction failed at higher cycle numbers. The DLC thin film (red) retained its low friction until 10 million of cycles and can be considered as slip-rolling resistant.

For further information please contact Dr. Ameneh Schneider: [email protected]

References

- F. O. Kolawole, S. K. Kolawole, L. B. Varela, A. F. Owa, M. A. Ramirez and A. P. Tschiptschin, Diamond-Like Carbon (DLC) Coatings for Automobile Applications, December 3rd 2020, IntechOpen, DOI: 10.5772/intechopen.95063. Available from: https://www.intechopen.com/online-first/74304 ↑

- T. Hosenfeldt, CO2-neutrale Mobilität als Herausforderung und Chance -Vom Antriebsstrang bis zum Elektrolyseur: Die Plasma-Oberflächentechnik entlang der Energiekette, Journal VIP – Vakuum in Forschung und Praxis, Februar 2021, Vol. 33, Nr. 1, DOI:10.1002/vipr.202100753 ↑

- H. Czichos and M. Woydt, Systematic Diagnosis of Friction and WearPart A.Introduction to Tribology and Tribological Parameters, p. 1-15 andPart B.Tribological Testing and presentation of data, p. 16-32.In: ASM Handbook Friction, Lubrication, and Wear Technology, Vol. 18, December 2017, ASM International, ed. G.E. Totten, ISBN-13: 978-1-62708-141-2, ISBN-10: 1-62708-141-0 ↑

- M. Woydt, Modern methods to retrieve innovative material solutions for tribosystems, Lubrication Engineering, 2000, May, p. 26-30 ↑

- H. Mano and T. Ohana, Evaluation of anti-adhesion characteristics of diamond-like carbon filmusing high-frequency, linear-oscillation tribometer, WEAR, 386-387 (2017) 188-194 ↑

- D. Klaffke, J. Brand, C. Brand and R. Wittorf, Tribological characterisation of a-C:H coatings at room temperature; effect of counterbody material, Proc. 14th Int. Coll. Tribology, (ed. W. J. Bartz), TAE Esslingen, Jan 2004, Vol. I, 605-614 ↑

- R. Wäsche, A. R. Jayachandran, G. Brandt, T. Schmid, T. Tamura and T. Nakase, Friction and wear of a-C:H coatings under influence of temperature in boundary lubricated oscillating sliding, Tribologie + Schmierungstechnik, 65. Jahrgang, 5/2018, p. 28-37 ↑

- K. Ohara, K. Hanyuda, Y. Kawamura, K. Omura, I. Kameda, N. Umehara and H. Kousaka, Analysis of Wear Track on DLC Coatings after Sliding with MoDTC-Containing Lubricants, Tribology Online, 2017, Vol. 12, Issue 3, p. 110-116, https://doi.org/10.2474/trol.12.110 ↑

- A. Schneider, D. Steinmüller-Nethl, F. Franek, Enhanced tribological performances of nanocrystalline diamond film, Int. J. of Refractory Metals and Hard Materials, Vol. 28 (1), 40-50, 2010

- C-A. Manier, G. Theiler, D. Spaltmann, M. Woydt, H. Ziegele, Benchmark of thin film coatings for lubricated slip-rolling contacts, WEAR 268 (2010) 1442-1454, http://dx.doi.org/10.1016/j.wear.2010.08.004 ↑

- M. Woydt and R. Shah, Newly designed innovative 2disk Test Instrument to study friction under slip rolling conditions, Labcompare, 25.08.2020, https://www.labcompare.com/10-Featured-Articles/567541-Innovative-2-Disk-Test-Instrument-to-Study-Friction-Under-Slip-Rolling-Conditions/ ↑

Be the first to comment