The article is written by Riya Veluri, an editorial team member of Industrial Lubricants. After her graduation, Riya works as a website developer & SEO specialist in Lubrication & Tribology Industry & writes technical articles on Lubricants, Lubrication, Reliability & sustainability.

Reciprocating Sliding Friction and Wear test

Friction and wear are two important factors affecting mechanical components’ performance and durability. Reciprocating sliding friction and wear tests evaluate the tribological properties of materials and coatings under simulated sliding conditions. These tests can provide valuable information on the wear resistance, friction coefficient, and wear mechanism of materials and coatings, which can be used to optimize the design and performance of mechanical components.

Reciprocating Sliding Friction and Wear Test rig Working Principle

A reciprocating sliding friction and wear test rig is a device used to study materials’ wear and friction properties under sliding conditions. It simulates the conditions of real-world applications such as gears, bearings, and other mechanical components.

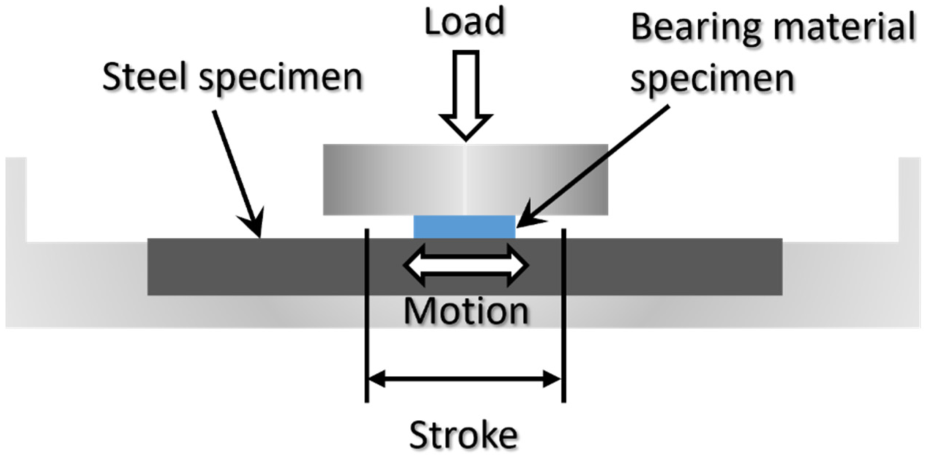

The test rig typically consists of a stationary block and a moving block that are in contact with each other. The moving block is attached to a reciprocating mechanism that moves it back and forth against the stationary block. The contact between the two blocks is typically maintained by a normal load applied through a load cell.

The motion of the moving block can be controlled to simulate different sliding conditions such as velocity, frequency, amplitude, and temperature. The surfaces of the blocks can also be prepared with different surface finishes, coatings, or lubricants to study the effects on wear and friction.

The wear and friction properties of the materials can be measured using various techniques such as surface profilometry, optical microscopy, and tribology testing. These measurements can provide information on the wear rate, coefficient of friction, and surface roughness of the materials.

The friction coefficient is the ratio of the friction force to the normal load, while the wear rate is the loss of material in the sliding distance. Both the parameters are important in evaluating the tribological properties of materials and coatings.

The wear mechanism of the material can also be studied by examining the worn surfaces of the two blocks after the test. The wear debris can be analyzed using various techniques, such as scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS) to identify the wear type and the worn material composition.

It’s important to note that the results obtained from a reciprocating sliding friction and wear test rig are specific to the test conditions used and may not necessarily apply to all applications. Real-world applications can be complex and influenced by factors such as temperature, humidity, pressure, and other environmental conditions, which may not be present in the lab test.

But with the help of today’s modern technology, reciprocating sliding friction and wear test rigs can test under different environmental conditions. Also, some test rigs are designed to operate at high temperatures, high pressures, or in corrosive environments. This can provide valuable information on how the materials will perform in those conditions and how they may be affected by changes in temperature, pressure, or exposure to different chemicals.

The test rig can evaluate the performance of different surface treatments such as hardening, nitriding, and electroplating. This can provide valuable information on how different surface treatments can be used to improve the performance of mechanical components.

Some reciprocating sliding friction and wear test rig can also be used to study the effect of different loading conditions. Some test rig can be designed to apply different types of loadings such as cyclic loading, impact loading, or vibration loading. This can provide valuable information on how the materials will perform under different loading conditions, and how they may be affected by changes in loading frequency, amplitude, or direction.

Different Kinds of Modern reciprocating sliding friction and wear test rig

- In modern technology, reciprocating sliding friction and wear test rig can be designed and configured in different ways to suit the specific requirements of the study. For example, some test rigs may use a pin-on-disk configuration, where a small pin is pressed against a larger disk, while others may use a block-on-block configuration, where two blocks are pressed against each other.

- Another common test rig design is a four-ball configuration, which is used to study the tribological behavior of lubricants. In this configuration, a load is applied to three stationary balls that are pressed against a rotating fourth ball. The wear and friction properties of the lubricant can be measured by analyzing the wear on the balls and the coefficient of friction.

- In some test rig designs, it is also possible to measure the temperature at the interface between the two blocks; this can be done through a thermocouple attached to the interface. This can give an idea of the heat generated due to the friction and wear.

- Another Reciprocating sliding friction and wear test rig can be tested under different lubrication conditions. Different lubricants can significantly impact the wear and friction properties of materials. By testing under different lubrication conditions, it’s possible to determine the optimal lubricant for a given application. This can help to improve the performance and extend the lifespan of the mechanical components.

Conclusion

In conclusion, reciprocating sliding friction and wear test rig are important tools in tribology and materials science. It provides a controlled environment for studying materials’ wear and friction properties under different sliding conditions. The results obtained from the test rig can be used to optimize the design of mechanical components and improve their performance and reliability.

References and further reading: https://www.sciencedirect.com/science/article/pii/014294189090040K

Leave a Reply

You must be logged in to post a comment.

One of the challenges of this equipment is the start/stop at every reciprocating movement. Adhesive wear at start/stop is likely to occur while in most applications this is not the case (only in piston movement).