Artificial Intelligence in Tribology

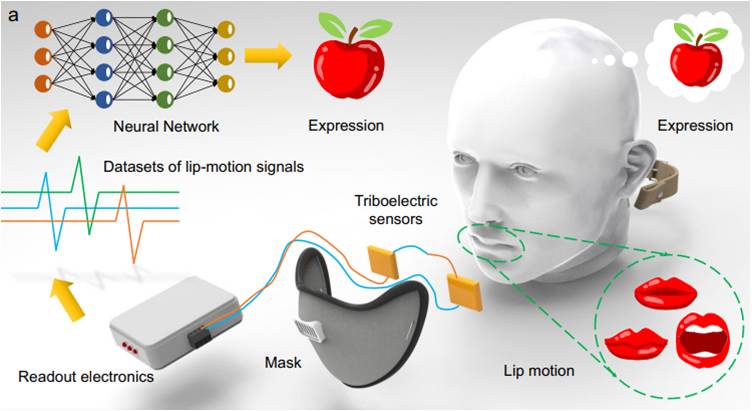

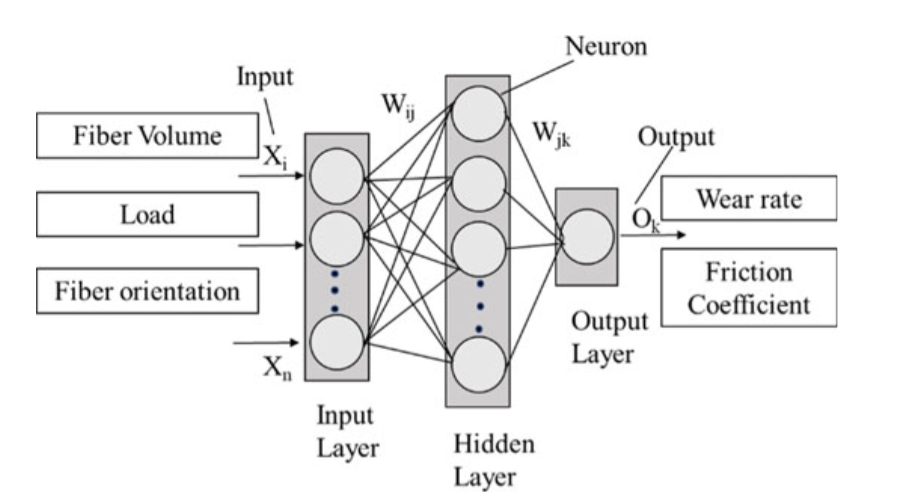

Introduction Traditional ways of testing tribological properties are both time-consuming and costly. However, there’s a promising solution that involves using Artificial Intelligence (AI) to make the process more efficient. This new method employs artificial neural […]